HFST high-friction resin surface structure and preparation method thereof

A high-friction, superficial technology, applied in the direction of on-site coagulation pavement, roads, buildings, etc., can solve the problems of stone falling off particles, reduced structural depth, insufficient cohesion, etc., and achieves low crushing value, Good angularity, improved flatness and roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

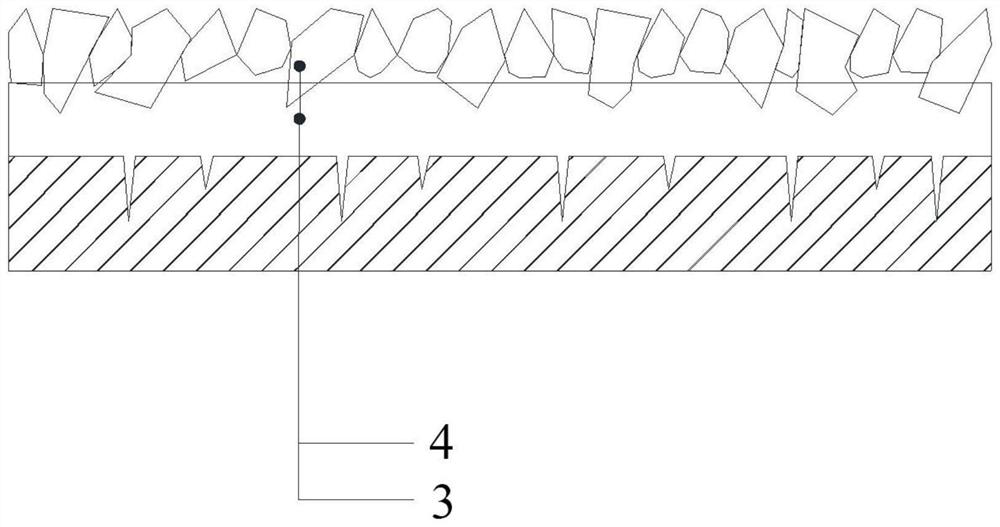

[0054] Embodiment 1: Construction is carried out on the asphalt pavement of a heavy-duty expressway in Jiangsu according to the following steps:

[0055] (1) Spray the super-sticky modified epoxy resin layer on the original asphalt pavement. The super-sticky modified epoxy resin bonding layer is configured in the mixing pipe of the spraying equipment according to the proportion of each component. According to The calculation of mass parts includes 45 parts of bisphenol A glycidyl ether type epoxy resin, 25 parts of methyl tetrahydrophthalic anhydride curing agent, 15 parts of toughened polyacrylate, 10 parts of silicone, and 5 parts of glass fiber. The mixer is stirred for 1 minute, the mixing tube is 1.5m long, the diameter is 50mm, and the rotating speed is 250R.p.m. Multiple extrusion spraying equipment are used for simultaneous stirring and simultaneous spraying. The extrusion pressure is 0.9Mpa, and the spraying amount is 2kg / m 2 , the spraying thickness is 2mm, and the d...

Embodiment 2

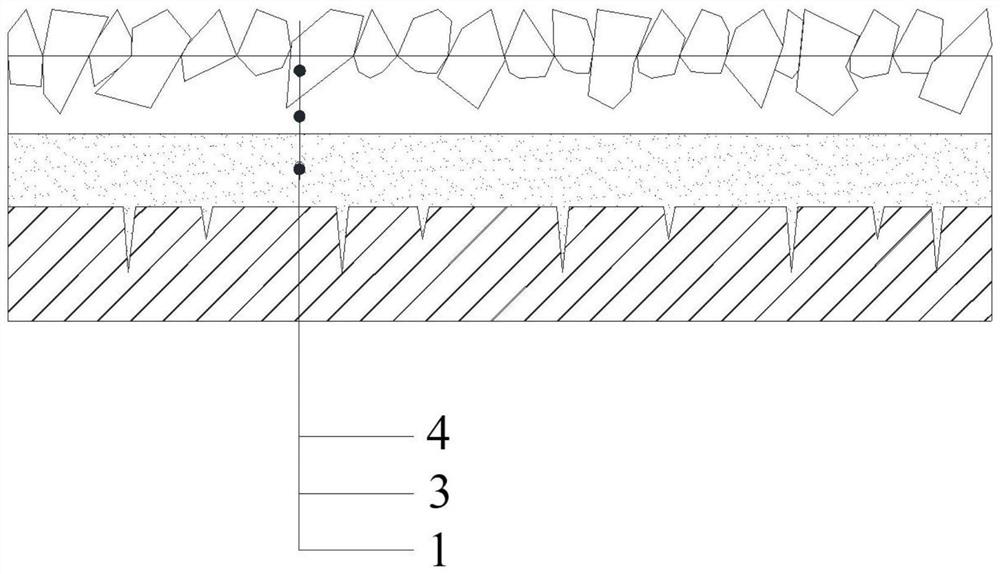

[0062] Example 2: A HFST high friction resin surface structure and its preparation method

[0063] In order to solve the cracking problem caused by the inconsistency between the surface of the high-friction resin and the asphalt pavement, and further improve its anti-skid performance and reduce noise, this technology has been improved.

[0064] The overtaking lane of an expressway in Jiangsu has been in operation for more than 10 years, and the anti-skid performance has declined. It is urgent to carry out anti-skid improvement. The construction is carried out according to the following steps:

[0065] (1) Spray a flexible resin coordinated sealing layer on the original asphalt pavement, so that the surface of the high friction resin can be deformed in harmony with the original asphalt pavement. The flexible resin is configured in the mixing tube of the spraying equipment according to the proportion of each component. Calculated according to the mass parts, it consists of 40 pa...

Embodiment 3

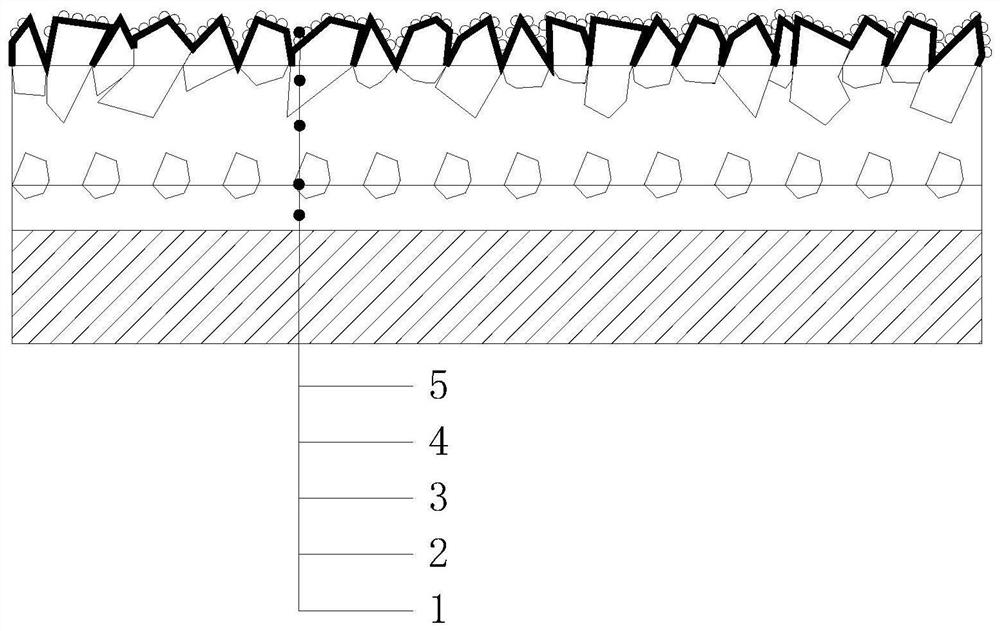

[0073] Embodiment 3: HFST high friction resin surface structure and its preparation method

[0074] In order to further solve the problems of local peeling and high noise on the surface of high-friction resin, and further improve its anti-skid performance, this technology has been improved. This invention is implemented in a heavy lane of an expressway with an operation period of more than 10 years, as follows Step construction:

[0075] (1) Using the W2000 ultra-precision milling process of the multi-point laser leveling system to perform ultra-precise milling on the original asphalt pavement, the number of milling drums is 1100, the laser leveling system has 6 points, and the driving speed is 2m / min , the milling depth is 7mm, and the flatness index IRI after milling is 1.3m / km.

[0076] (2) After the ultra-precise milling, use the Case cleaning machine to preliminarily clean the milled objects on the interface, open the traffic for 1 day, use the impact force and shear str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com