Composite photocatalyst for treating organic pollutants in wastewater as well as preparation method and application of composite photocatalyst

A technology for organic pollutants and wastewater treatment, which is used in catalyst activation/preparation, water pollutants, physical/chemical process catalysts, etc. It can solve the problems of low utilization of sunlight, lack of research on photocatalytic effects, etc., and improve the conductivity. , The effect of improving photocatalytic performance and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

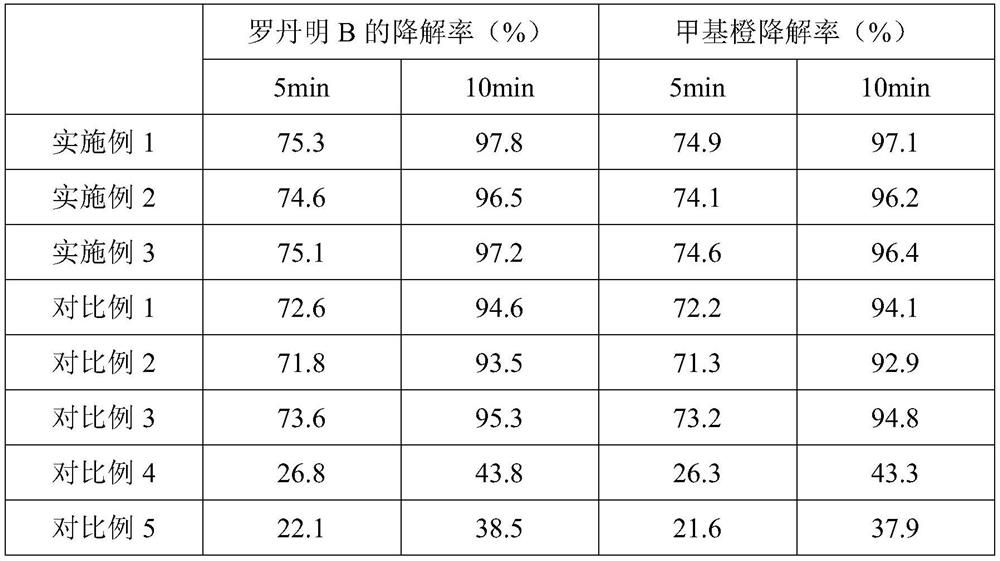

Embodiment 1

[0030] A preparation method of a composite photocatalyst for treating organic pollutants in wastewater, the preparation method comprising the following steps:

[0031] (1) Dissolve 1 mol of bismuth nitrate, 0.02 mol of copper nitrate and 0.03 mol of nickel nitrate into 65 mL of ethylene glycol solvent, then add 4 mol of urea and continue to stir for 30 min, then react in hydrothermal reaction at 150 °C for 16 h, centrifuge the solid after the reaction Separation, washing with deionized water for 3 times, and drying at 90°C for 13 hours to obtain bismuth oxide co-doped with copper and nickel;

[0032] (2) Take the copper and nickel co-doped bismuth oxide prepared in step 1) and add the ethylene glycol solution of 1mol / L bismuth nitrate to 20mL, get 10mL concentration and add the sodium metasilicate aqueous solution that is 1mol / L In the ethylene glycol solution of bismuth, stir magnetically for 35 minutes; slowly add aqueous sodium hydroxide solution dropwise under stirring con...

Embodiment 2

[0034] A preparation method of a composite photocatalyst for treating organic pollutants in wastewater, the preparation method comprising the following steps:

[0035] (1) Dissolve 1 mol of bismuth acetate, 0.03 mol of copper chloride and 0.02 mol of nickel nitrate in 70 mL of ethanol solvent, then add 5 mol of urea and continue to stir for 40 min, then perform a hydrothermal reaction at 160°C for 14 h, and centrifuge the solid after the reaction , washed with deionized water for 3 times, and dried at 100°C for 10 hours to obtain bismuth oxide co-doped with copper and nickel;

[0036](2) Take the copper and nickel co-doped bismuth oxide prepared in step 1) and add it to the ethanol solution of 1mol / L bismuth chloride of 30mL, get 15mL of concentration and add the sodium metasilicate aqueous solution that is 1mol / L to the chloride In the ethanol solution of bismuth, stir magnetically for 40 minutes; slowly add potassium hydroxide aqueous solution dropwise under stirring conditi...

Embodiment 3

[0038] A preparation method of a composite photocatalyst for treating organic pollutants in wastewater, the preparation method comprising the following steps:

[0039] (1) Dissolve 1 mol of bismuth acetate, 0.01 mol of copper nitrate and 0.04 mol of nickel chloride into 60 mL of glycerol solvent, then add 3 mol of urea and continue to stir for 20 min, then perform a hydrothermal reaction at 140 ° C for 18 h, and after the reaction, the solid centrifuged, washed with deionized water three times, and dried at 80°C for 16 hours to obtain bismuth oxide co-doped with copper and nickel;

[0040] (2) Get the copper and nickel co-doped bismuth oxide that will step 1) prepare and add the glycerin solution of 1mol / L bismuth acetate of 10mL, get 5mL concentration and add the sodium metasilicate aqueous solution that is 1mol / L to acetic acid In bismuth glycerol, stir magnetically for 30 minutes; slowly add ammonia solution dropwise under stirring conditions to adjust pH = 10; continue sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com