Comprehensive resource recovery method for laterite-nickel ore

A technology of lateritic nickel ore and recovery method, which is applied in the field of metallurgy, can solve the problems of large amount of waste residue and wastewater, high carbon emission, and long construction period, etc., to reduce equipment investment costs, low-carbon recycling, and reduce carbon emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The composition of laterite nickel ore to be treated in this embodiment is: Ni 0.75wt.%, Co 0.061wt.%, Mn0.57wt.%, Sc 0.0055wt.%, Fe 47.8wt.%, Mg 0.43wt.%, Al 3.98wt.% and Cr1.23wt.%.

[0045] The resource comprehensive recovery method of the laterite nickel ore of the present embodiment may further comprise the steps:

[0046] (1) Mix laterite nickel ore and concentrated sulfuric acid uniformly at a mass ratio of 5:1, and then heat them in a tubular atmosphere furnace to 250°C for heat treatment for 1 hour to obtain modified laterite nickel ore.

[0047] (2) Mix water and modified laterite nickel ore uniformly at a liquid-solid ratio (ratio in mL / g) of 10:1, and then transfer to a high-pressure reactor for hydrolysis reaction. The hydrolysis temperature is 200°C. The time is 1h, and the laterite nickel ore leaching solution and leaching slag are obtained. During this process, the leaching rates of Ni, Co, Mn, Sc, Fe, Mg, Al and Cr are 96.36%, 76.06%, 82.18%, 87.14%, 5...

Embodiment 2

[0052] The composition of laterite nickel ore to be treated in this embodiment is: Ni 0.75wt.%, Co 0.061wt.%, Mn0.57wt.%, Sc 0.0055wt.%, Fe 47.8wt.%, Mg 0.43wt.%, Al 3.98wt.% and Cr1.23wt.%.

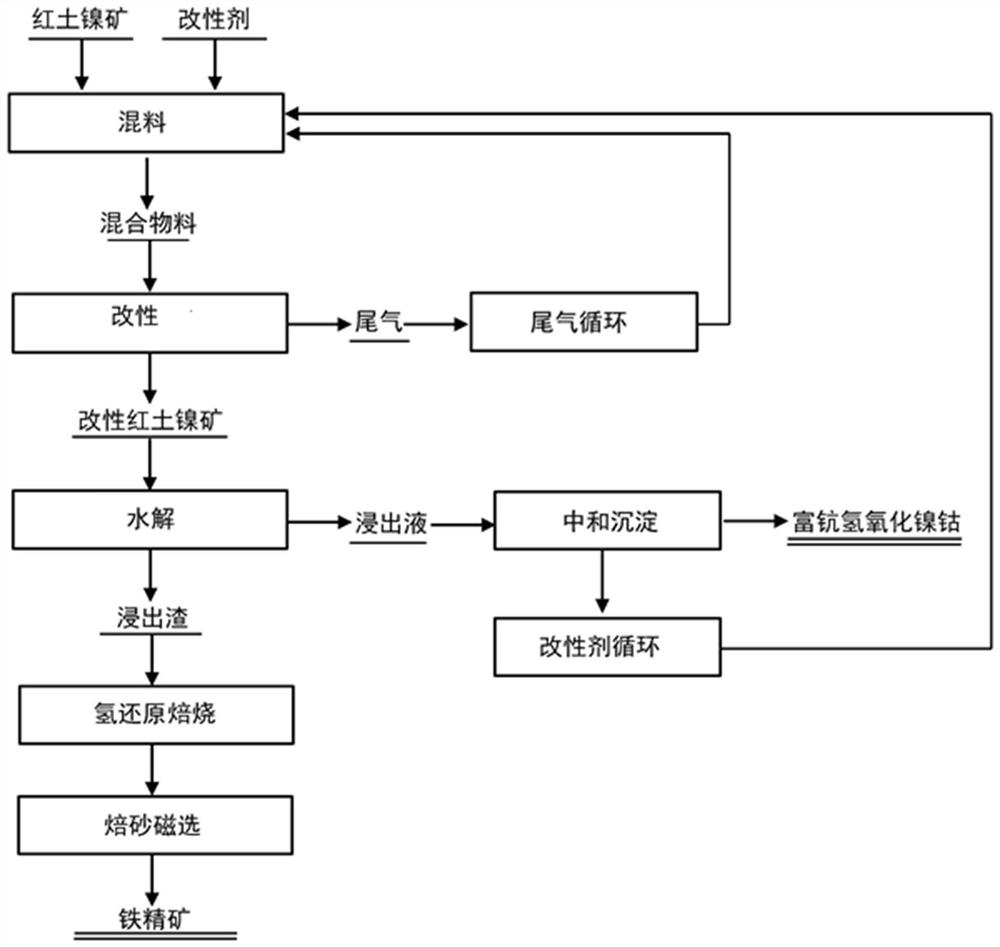

[0053] The resource comprehensive recovery method of the laterite nickel ore of the present embodiment, its process flow chart is as follows figure 1 shown, including the following steps:

[0054] (1) Mix the laterite nickel ore and ammonium sulfate uniformly at a mass ratio of 1:1, and then heat them in a tubular atmosphere furnace to 350°C for heat treatment and modification for 3 hours to obtain modified laterite nickel ore. The heat treatment modification process The ammonia produced in the process is absorbed with 0.5mol / L dilute sulfuric acid, and the ammonium sulfate solution obtained evaporates, concentrates, and crystallizes to prepare ammonium sulfate, and returns to the mixing process of step (1) for recycling.

[0055] (2) Mix water and modified laterite nickel ore uniforml...

Embodiment 3

[0060] The composition of laterite nickel ore to be treated in this embodiment is: Ni 0.75wt.%, Co 0.061wt.%, Mn0.57wt.%, Sc 0.0055wt.%, Fe 47.8wt.%, Mg 0.43wt.%, Al 3.98wt.% and Cr1.23wt.%.

[0061] The resource comprehensive recovery method of the laterite nickel ore of the present embodiment, its process flow chart is as follows figure 1 shown, including the following steps:

[0062] (1) Mix the laterite nickel ore and ammonium bisulfate uniformly at a mass ratio of 1:1, and then heat them in a tubular atmosphere furnace to 350°C for heat treatment and modification for 3 hours to obtain modified laterite nickel ore. The ammonia produced in the process is absorbed with 0.5mol / L dilute sulfuric acid to obtain ammonium sulfate solution, evaporated, concentrated, and crystallized to prepare ammonium sulfate, and return to the mixing process of step (1).

[0063] (2) Mix water and modified laterite nickel ore uniformly at a liquid-solid ratio (ratio in mL / g) of 10:1, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com