Photocuring composition, coating and preparation method thereof, carbon fiber prepreg and preparation method thereof, and fiber composite material

A composition and light-curing technology, applied in the field of fiber composite materials, can solve the problems of easy hydrolysis and high activity, and achieve the effect of maintaining low viscosity, excellent operability, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

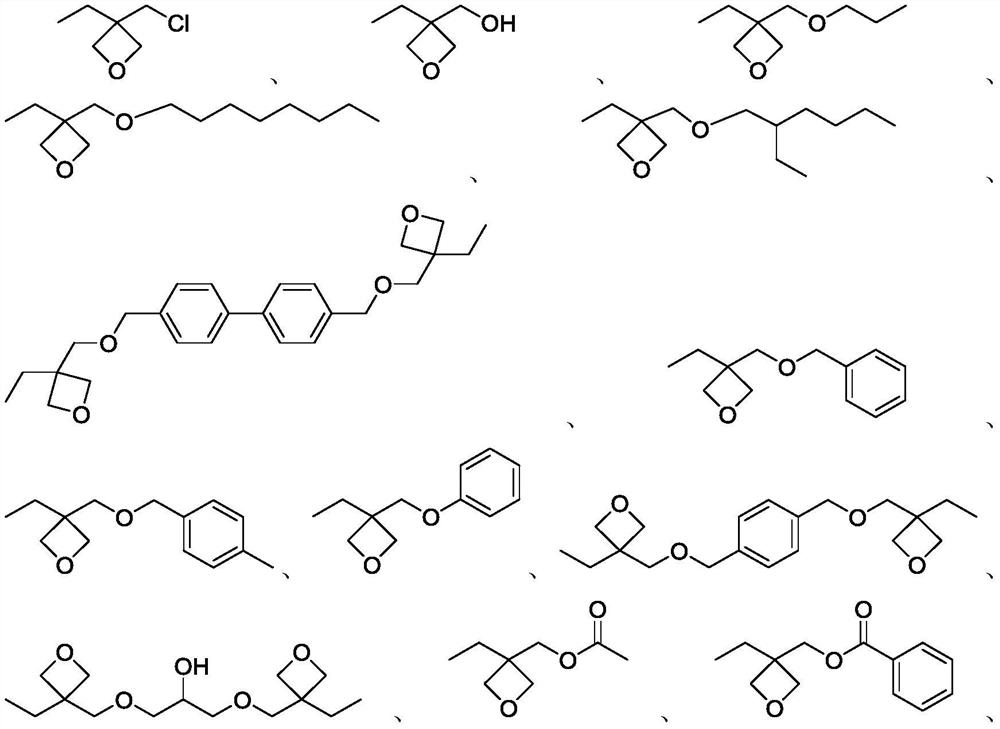

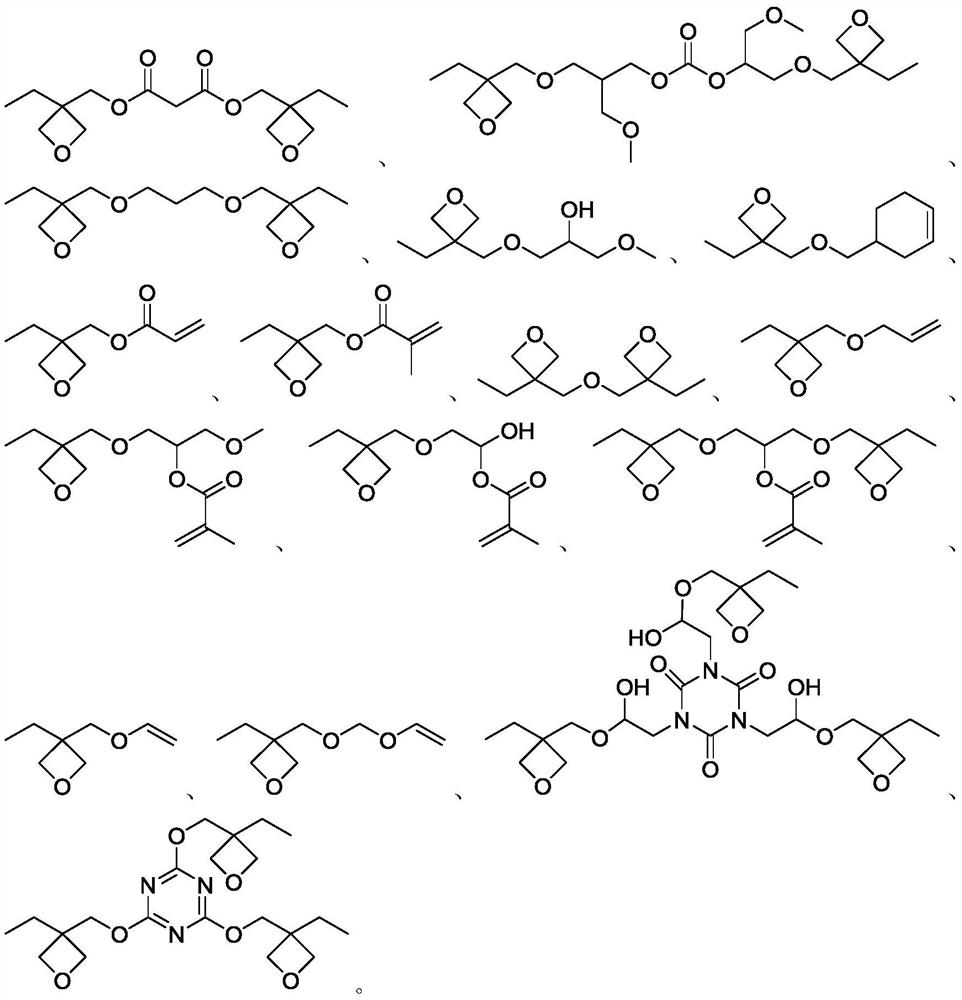

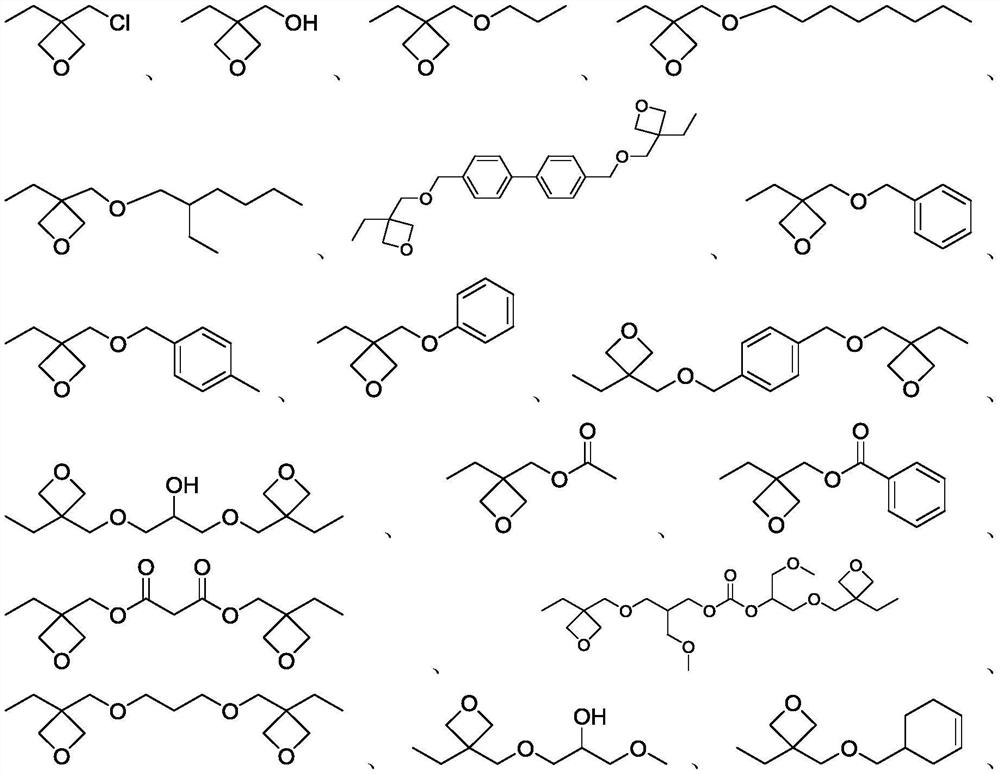

Method used

Image

Examples

preparation example Construction

[0055] In yet another typical embodiment of the present application, a method for preparing any of the above-mentioned coatings is provided, including: step S1, under ultraviolet light irradiation, the monomer and cationic photoinitiator in the photocuring composition Mixing to form a photoinitiating solution; step S2, mixing the photosensitive resin in the photocuring composition with the photoinitiating solution at a temperature below 20°C to obtain a system to be cured. When the coating also includes additives, the additives are added in step S2 .

[0056] When mixing the monomer and the cationic initiator, use ultraviolet light to irradiate the cationic initiator to initiate the formation of an intermediate; It can ensure the uniform mixing of the resin and the photoinitiating solution, and can avoid the polymerization of the photosensitive resin, thereby forming a system to be cured with low viscosity and excellent wettability, which is conducive to large-area roll coatin...

Embodiment 11

[0084] The viscosity of component 60g is 1-bis(3-ethyloxetanyl-3-methoxy)methanol-butyl ether (A), 5g bis(4-tert-butylphenyl)iodonium hexa Fluorophosphate (B) mixed evenly, stirred under mercury lamp (100mv / cm 2 , 2min), then add 35g of bisphenol A epoxy resin (C) at 0°C (temperature 1) to form a system to be cured, with a viscosity of 783cps, stir evenly, and let it stand for use. Put the dried carbon fiber woven cloth layup (10cm*50cm, 10 layers) into a vacuum bag and place it in a molding mold at a temperature of 15°C (temperature 2), and depressurize it to -0.1MPa by a vacuum pump, and put the above-mentioned to-be-cured The system is injected into a vacuum bag at 0.2MPa to form a fiber prepreg.

[0085] After the injection was completed, the temperature of the mold was raised to 30° C. (temperature 3), and demoulding was carried out after 5 minutes to obtain a carbon fiber composite laminate with a carbon fiber woven cloth volume content Vf of 45%.

[0086] By changing ...

Embodiment 21

[0093] The difference from Example 1 is that the component B content is 1.9 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com