Silicon combined silicon carbide diesel particulate filter and preparation method thereof

A particle filter and silicon carbide technology, which is applied in ceramic products, mechanical equipment, machines/engines, etc., can solve the problems of poor micropore connectivity, high production cost, and difficulty in firing, and achieve thermal expansion coefficient and thermal conductivity matching. The effect of high degree of hardness and reducing the risk of product cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

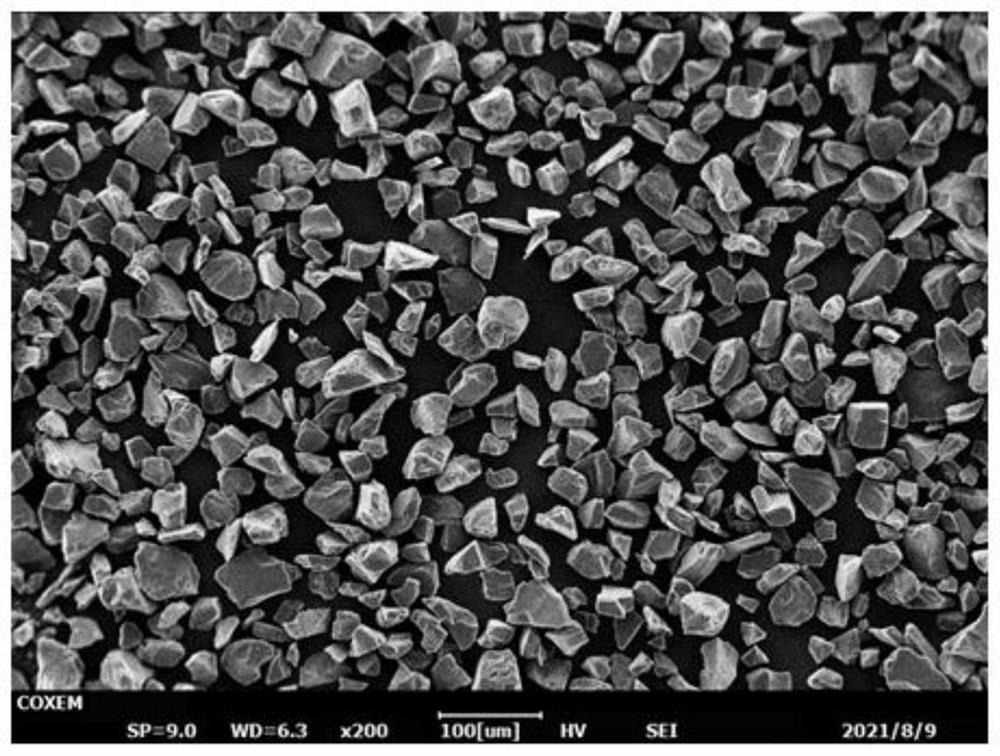

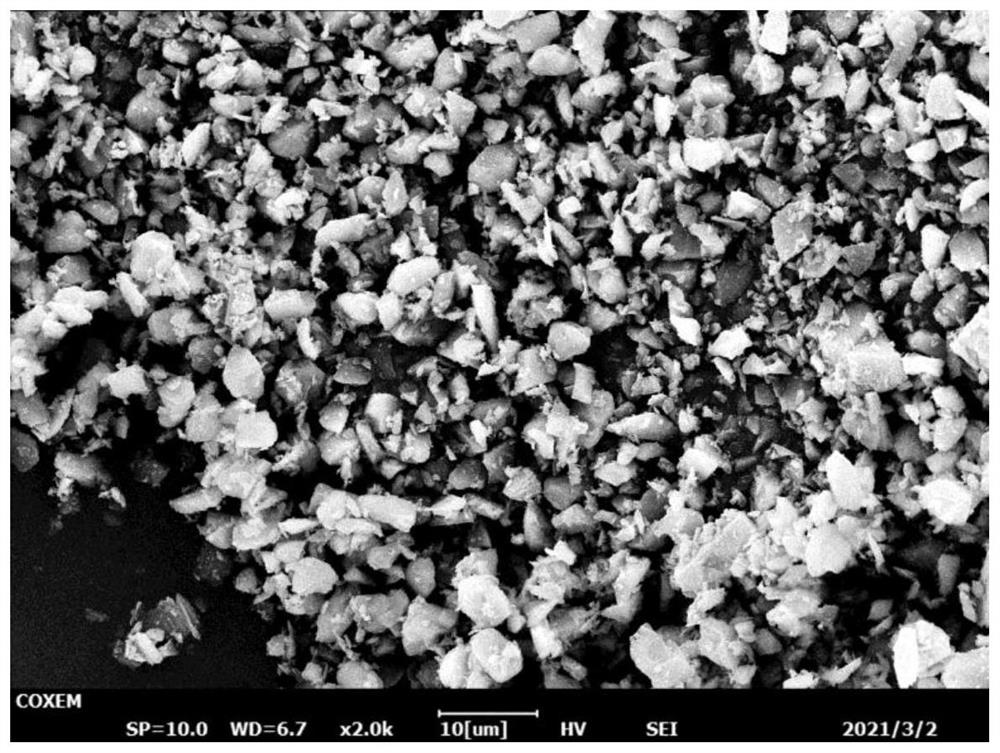

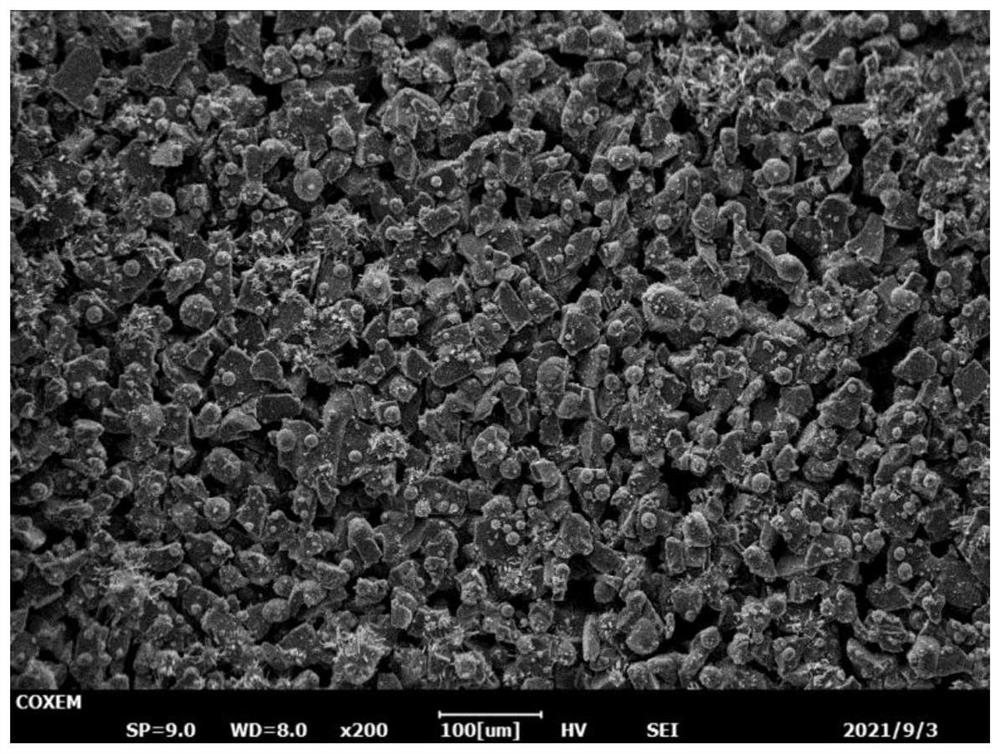

[0047] (1) Mix 75% by weight of 25-28 μm silicon carbide micropowder and 25% by weight of 3-6 μm metal silicon by dry method. Taking the total weight of inorganic main materials as 100%, plus 3% by weight of starch of 20-25 μm, and 9% by weight of organic binder, a homogeneous mixture with close packing is prepared. Wherein the addition amount of the binder and pore-forming agent is externally added on the basis of inorganic components, and the binder can be selected from methyl cellulose, PVA, PET, etc. In this embodiment, hydroxypropyl methyl cellulose is used; (2 ) Put the mixed powder in the kneading machine, add 22% by weight of water of the total powder and knead for 17 minutes, add 1.0% by weight of lubricant and 1% by weight of dispersant and knead for 25 minutes, the addition of the additive is It is added on the basis of the total mixed components to increase the plasticity, lubricity and surface activity of the mud. Organic additives such as soybean oil, butter, and s...

Embodiment 2

[0049] (1) Mix 75% by weight of 25-28 μm silicon carbide micropowder and 25% by weight of 3-6 μm metal silicon by dry method. Taking the total weight of inorganic main materials as 100%, adding 5% by weight of starch of 20-25 μm and 9% by weight of organic binder, a homogeneous mixture with close packing is prepared. Wherein the addition amount of the binder and pore-forming agent is externally added on the basis of inorganic components, and the binder can be selected from methyl cellulose, PVA, PET, etc. In this embodiment, hydroxypropyl methyl cellulose is used; (2 ) Put the mixed powder in the kneading machine, add 22% by weight of water of the total powder and knead for 17 minutes, add 1.0% by weight of lubricant and 1% by weight of dispersant and knead for 25 minutes, the addition of the additive is It is added on the basis of the total mixed components to increase the plasticity, lubricity and surface activity of the mud. Organic additives such as soybean oil, butter, an...

Embodiment 3

[0051] (1) Mix 75% by weight of 25-28 μm silicon carbide micropowder and 25% by weight of 3-6 μm metal silicon by dry method. Taking the total weight of inorganic main materials as 100%, plus 10% by weight of starch of 20-25 μm, and 9% by weight of organic binder, a homogeneous mixture with close packing is prepared. Wherein the addition amount of the binder and pore-forming agent is externally added on the basis of inorganic components, and the binder can be selected from methyl cellulose, PVA, PET, etc. In this embodiment, hydroxypropyl methyl cellulose is used; (2 ) Put the mixed powder in the kneading machine, add 22% by weight of water of the total powder and knead for 17 minutes, add 1.0% by weight of lubricant and 1% by weight of dispersant and knead for 25 minutes, the addition of the additive is Adding on the basis of the total mixed components, the purpose is to increase the plasticity, lubricity and surface activity of the mud, and organic additives such as soybean ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com