Wavelength-adjustable solid carbon dot and preparation method thereof

A carbon dot, solid state technology, applied in chemical instruments and methods, nanocarbon, nanotechnology for materials and surface science, etc., can solve problems such as limiting the application of carbon dots, and achieve the effect of high repeatability and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

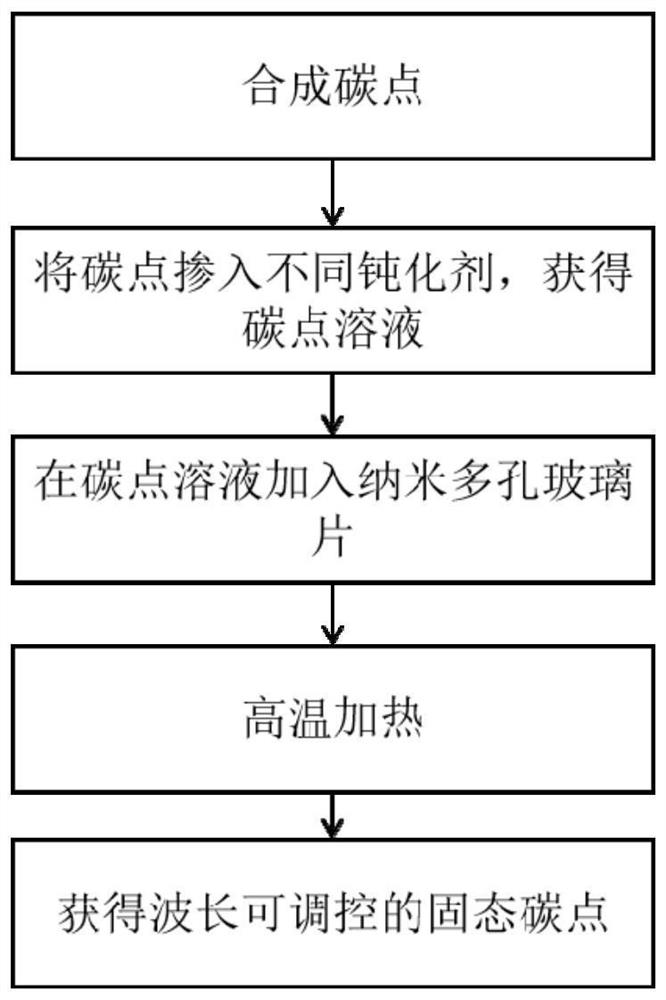

[0035] The invention provides a preparation method of wavelength-tunable solid carbon dots, such as figure 1 shown, including the following steps:

[0036] S1. Mix citric acid and urea in a mass ratio of 1:0.6 to 4, heat at 160 to 200°C for 6 to 12 hours, cool, dialysis purification, freezing, and vacuum drying to obtain carbon dot powder; the dialysis purification time For 24-72h, the size of the dialysis bag is 3500-500D.

[0037] S2. Dissolve the carbon dot powder in the passivating agent, and configure it into a carbon dot solution;

[0038] The passivating agent is a composite solvent of one or more solvents in sulfuric acid, phosphoric acid, boric acid and nitric acid;

[0039] The mass-volume ratio of the carbon dot powder to the passivating agent is 1-2 mg: 50-200 mL.

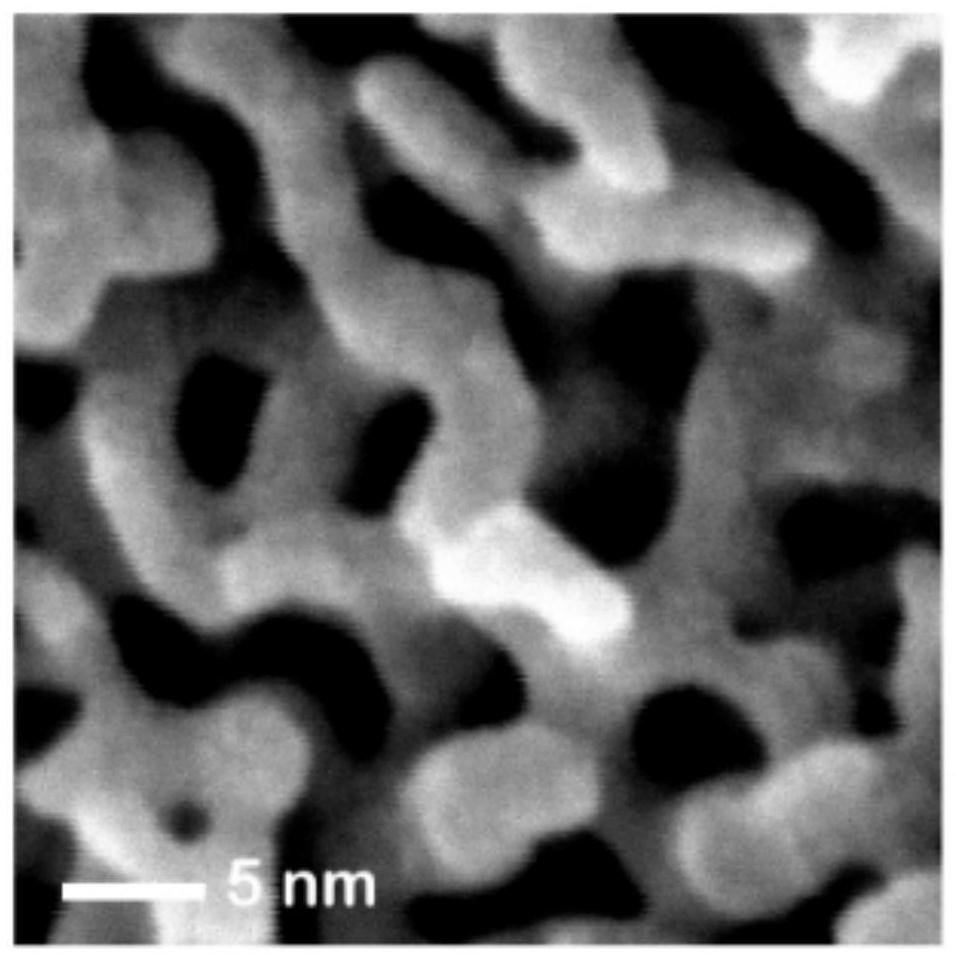

[0040] S3. Immerse the nanoporous glass sheet in the carbon dot solution.

[0041] S4, react under the condition of 140~200℃ for 4~8h, take out the nanoporous glass sheet, and dry to obtain the soli...

Embodiment 1

[0049] Weigh 1 g of citric acid and 2 g of urea into a beaker, grind evenly, add 30 mL of deionized water, stir evenly, put it into the inner tank of a polytetrafluoroethylene reactor, put the reactor into an oven, and set the reaction temperature to 160 ℃, the reaction time is 8h; after the reaction is over, put it into a 3500D dialysis bag, dialyze for 36h, and further purify the reactant; collect the liquid in the dialysis bag, put it into a freeze dryer, and obtain a powder sample.

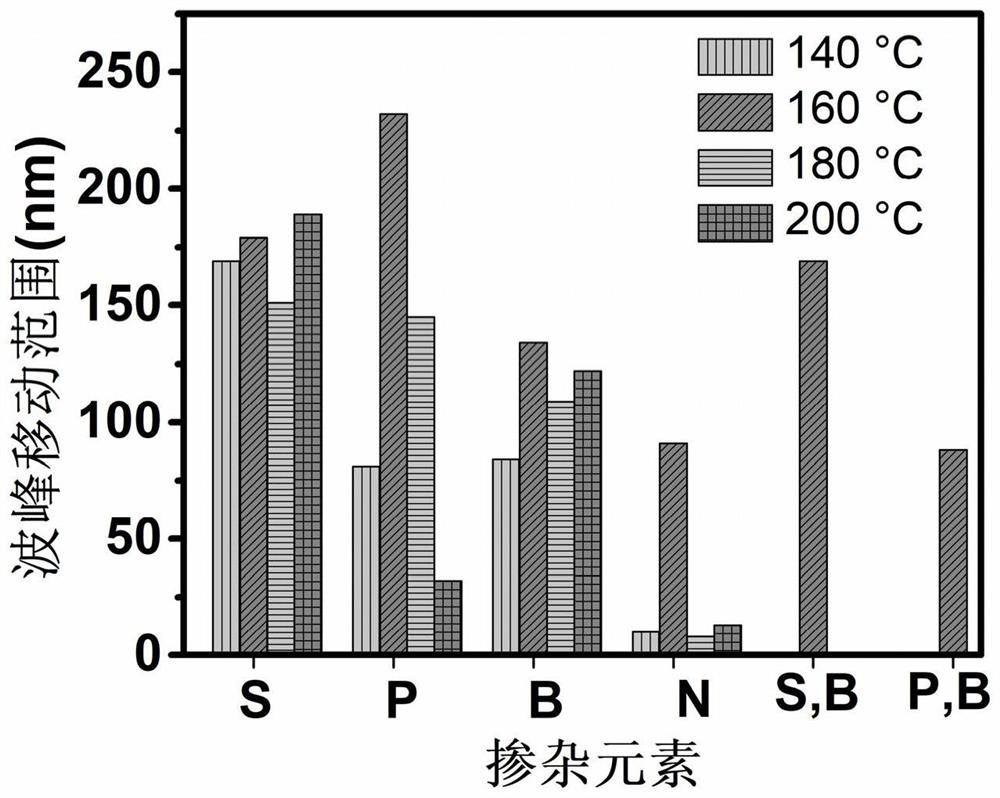

[0050] Dissolve 0.5 mg of powdered carbon dots in 5 mL of H 2 SO 4 , ultrasonic for 30 min to obtain a uniform carbon dot solution; take 1 nanoporous glass sheet, heat it in a reaction furnace at 200 °C for 6 h; then, dry it at a low temperature of 40 °C for 120 min to obtain a nanoporous glass sheet based Sulfur-doped solid carbon dots, labeled as S-CDs. Its fluorescence spectrum is Figure 4 As shown in the figure, it can be seen from the figure that its wavelength can be adjusted from 38...

Embodiment 2

[0052]Weigh 1 g of citric acid and 4 g of urea into a beaker, grind evenly, add 30 mL of deionized water, stir evenly, put it into the inner tank of a polytetrafluoroethylene reactor, put the reactor into an oven, and set the reaction temperature to 190 ℃, the reaction time is 5h; after the reaction is over, put it into a 2000D dialysis bag, dialyze it for 36h, and further purify the reactant; collect the liquid in the dialysis bag, put it into a freeze dryer, and obtain a powder sample.

[0053] Dissolve 1.2 mg of powdered carbon dots in 18 mL of H 3 BO 4 medium, ultrasonic for 30 min to obtain a uniform carbon dot solution; take 1 piece of nanoporous glass sheet, heat it in a reaction furnace at 180 °C for 5 h; then, dry it at a low temperature of 80 °C for 50 mins to obtain a nanoporous glass sheet-based Boron-doped solid carbon dots, labeled as B-CDs. Its fluorescence spectrum is Figure 5 As shown, it can be seen from the figure that its wavelength can be adjusted from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com