Modified graphene oxide/eleostearic acid maleic anhydride vinyl ester anticorrosive resin as well as preparation method and application thereof

A technology of acid anhydride vinyl ester and anti-corrosion resin, which is applied in the preparation of modified graphene oxide/maleic anhydride vinyl ester anti-corrosion resin, and in the field of modified graphene oxide/maleic anhydride vinyl ester anti-corrosion resin , can solve the problems of unfavorable graphene application, difficulty in dispersing graphene, poor compatibility between graphene and resin, etc., and achieve the effect of uniform appearance without layering, increasing labyrinth effect, and moderate viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of the modified graphene oxide / tung oleic acid maleic anhydride vinyl ester preservative resin, comprising the following steps:

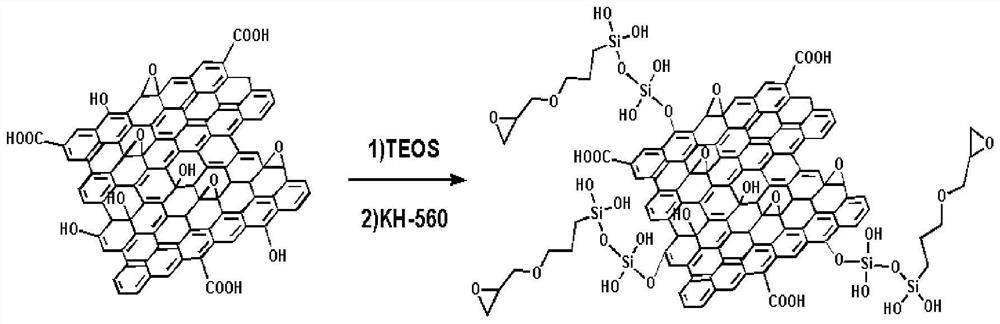

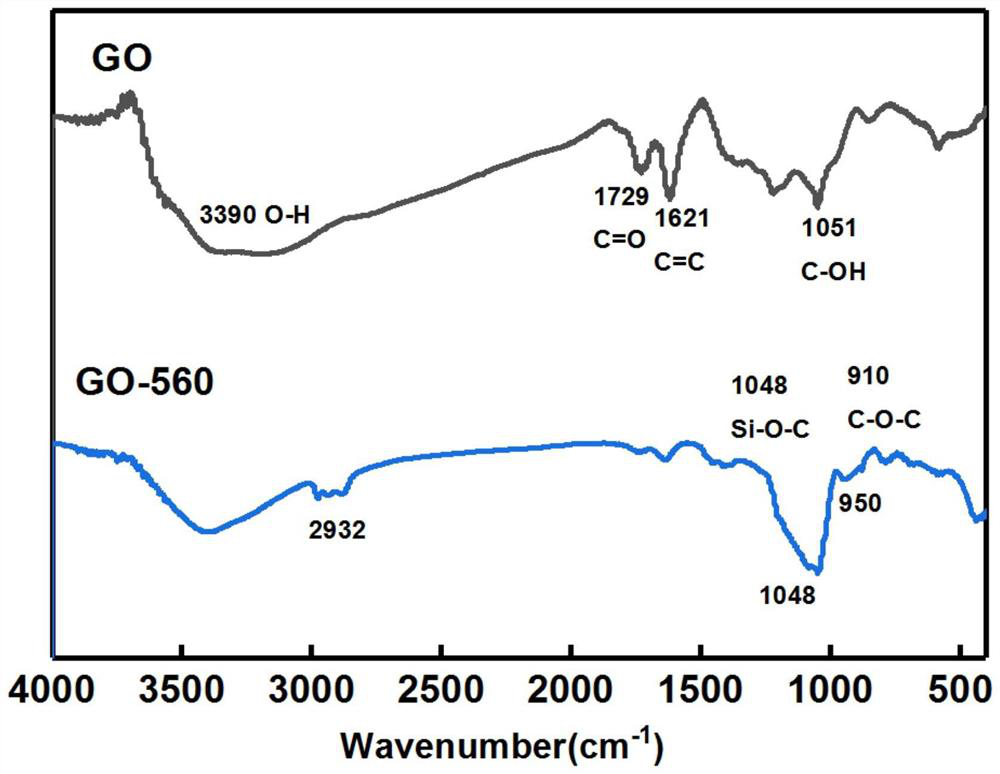

[0044] (1) Add 160g ethanol, 30g deionized water, 10g tetraethyl silicate (TEOS) in a 500mL round-bottom flask, stir at room temperature for 3 hours, then add 0.05g graphene oxide (GO), ultrasonically disperse for 30 min, then add 4g silane coupling agent KH-560, stir overnight, and then react at 70 °C, magnetically stirred for 8 hours, the end of the reaction is reduced to room temperature, the reaction product is centrifuged, The solid material obtained by centrifugation was washed 3 times each with water and ethanol, and then freeze-dried to give modified graphene oxide (GO-560).

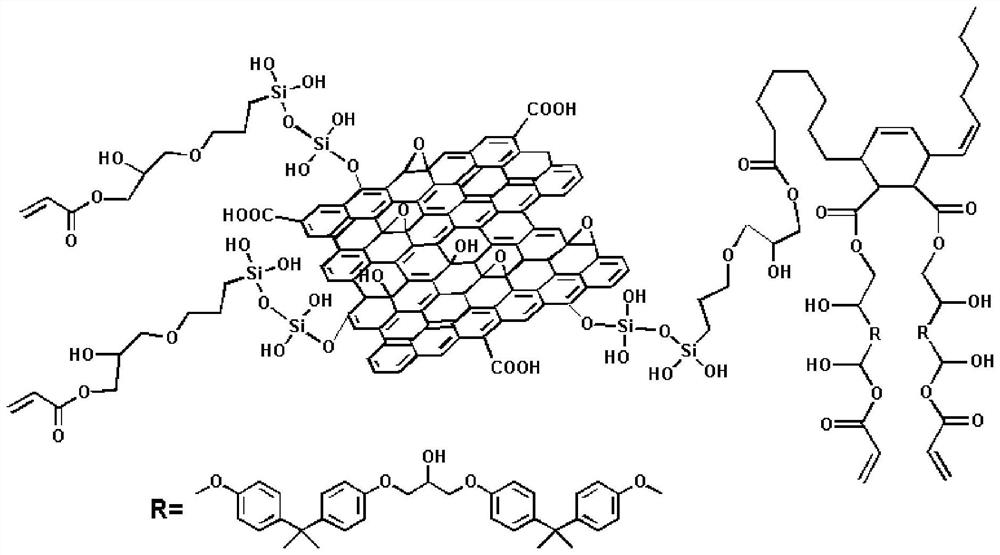

[0045] (2) In a 1000mL round bottom flask, 39.20g acrylic acid, 0.0394g polymerization inhibitor hydroquinone, 0.9846g catalyst benzyltriethylammonium chloride, 0.1980g GO-560, ultrasonic dispersion for 30 minutes, and then add 145.68g epoxy...

Embodiment 2

[0050] The preparation method of the modified graphene oxide / tung oleic acid maleic anhydride vinyl ester preservative resin, comprising the following steps:

[0051] (1) Add 160g ethanol, 30g deionized water, 10g tetraethyl silicate (TEOS) in a 500mL round-bottom flask, stir at room temperature for 3 hours, then add 0.05g graphene oxide (GO), ultrasonically disperse for 30 min, then add 4g silane coupling agent KH-560, stir overnight, and then react at 70 °C, magnetically stirred for 8 hours, the end of the reaction is reduced to room temperature, the reaction product is centrifuged, The solid material obtained by centrifugation was washed 3 times each with water and ethanol, and then freeze-dried to give modified graphene oxide (GO-560).

[0052](2) In a 1000mL round-bottom flask, 39.20g acrylic acid, 0.0394g polymerization inhibitor p-benzenediol, 0.9846g catalyst benzyltriethylammonium chloride, 0.0594g GO-560, ultrasonic dispersion for 30 minutes, and then add 145.68g epoxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com