Plant source amine oxidase as well as extraction method and application thereof

A technology of source amine oxidase and extraction method, applied in the field of active molecule extraction, can solve the problem of high biogenic amine content, and achieve the effects of simple preparation process, strong degradation ability and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Extraction of amine oxidase from peanut

[0022] In this example, amine oxidase is extracted from peanuts, and the specific steps are as follows:

[0023] Select legume seeds with uniform size and plump grains, rinse them with distilled water, and soak them in distilled water for 1-3 days at 35°C. The soaked seeds were evenly sown in the germination bed at roughly the same interval, cultivated in a 35°C incubator, watered regularly, and kept the ambient humidity appropriate. The cultivation was terminated after the seeds had germinated 3-5 cm.

[0024] Remove the plant sprouts obtained in step (1), add 3 times of 1M potassium phosphate buffer (pH 7.0), and put them into a homogenizer to pulverize. Four layers of gauze were filtered, and the filtrate was centrifuged at 4°C and 9500 r / min for 15 min, and the supernatant was taken as the crude enzyme extract.

Embodiment 2

[0025] Embodiment 2: Determination of crude enzyme liquid properties of peanut amine oxidase extract

[0026] The assay method for amine oxidase activity is as follows:

[0027] Take the phosphate buffer solution of pH 7.0, add peroxidase solution, guaiacol solution, and mixed solution of nine biogenic amines.

[0028] Take the above mixed solution into a 96-well plate, set the reaction temperature of the microplate reader at 25-55°C, add the amine oxidase extract before putting on the machine, and measure the absorbance change of the reaction system at 470nm within 10-30min. Here, an amine oxidase activity unit (U) is defined as A per minute in the enzyme reaction system 470 Increase the amount of enzyme required to a value of 0.01.

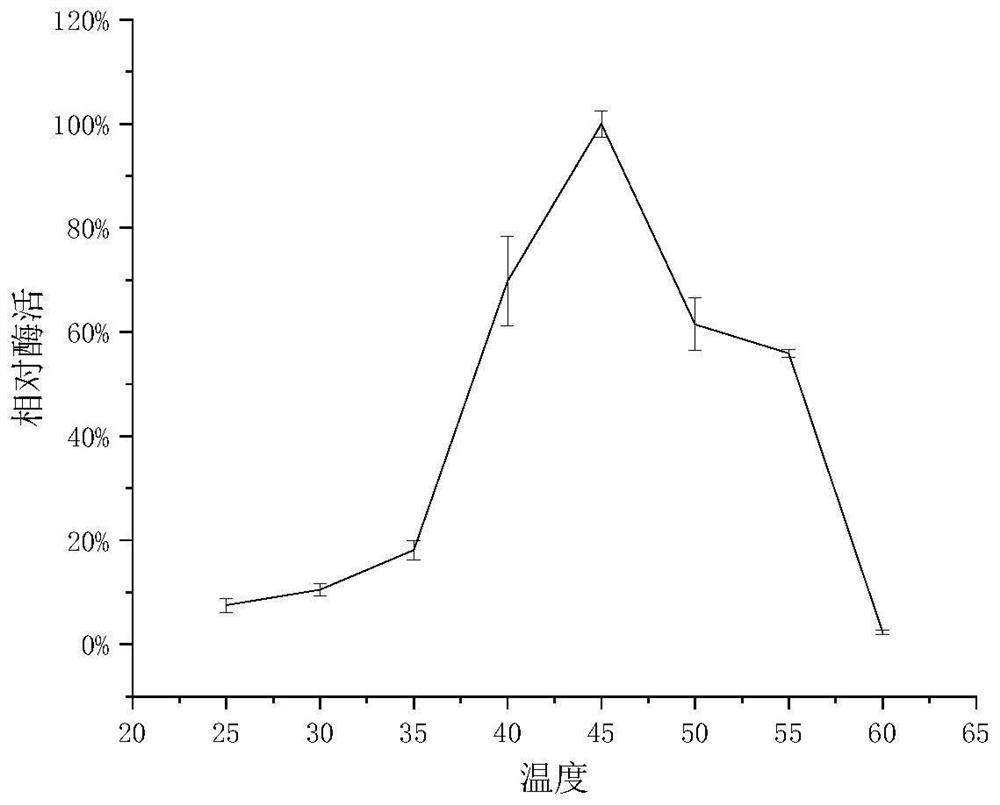

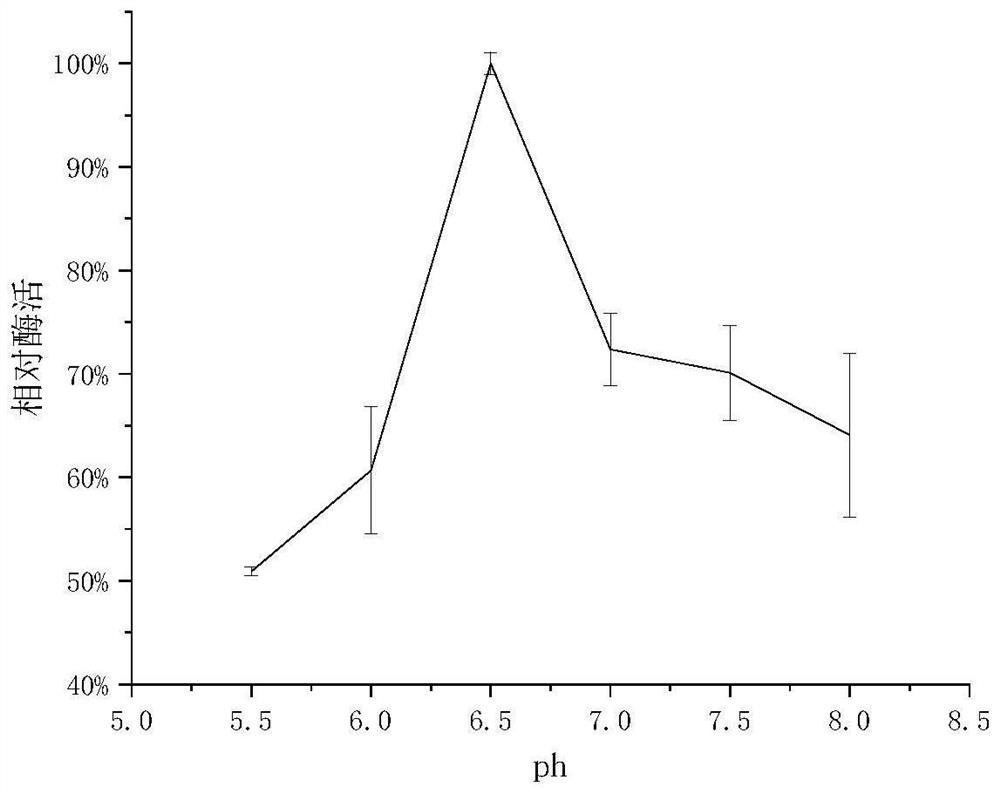

[0029] The amine oxidase activity of the crude enzyme extract at 25, 30, 35, 40, 45, 50, 55, and 60 ℃ was compared under the condition of pH 7.0, and the curve was drawn with the highest value of 100%. The amine oxidase activity of the crude ...

Embodiment example 3

[0032] Implementation Case 3: Verifying the amine-reducing effect of crude amine oxidase extract in peanuts

[0033] The specific operation steps of the treatment group were as follows: take 2ml of crude enzyme solution and 1ml of biogenic amine mixture and mix it, the mixture was left for 24h at 40°C; centrifuged at 10000r / min for 5min; Chromatographic determination of biogenic amines.

[0034] The untreated group was treated for 24 hours with only the addition of buffer solution.

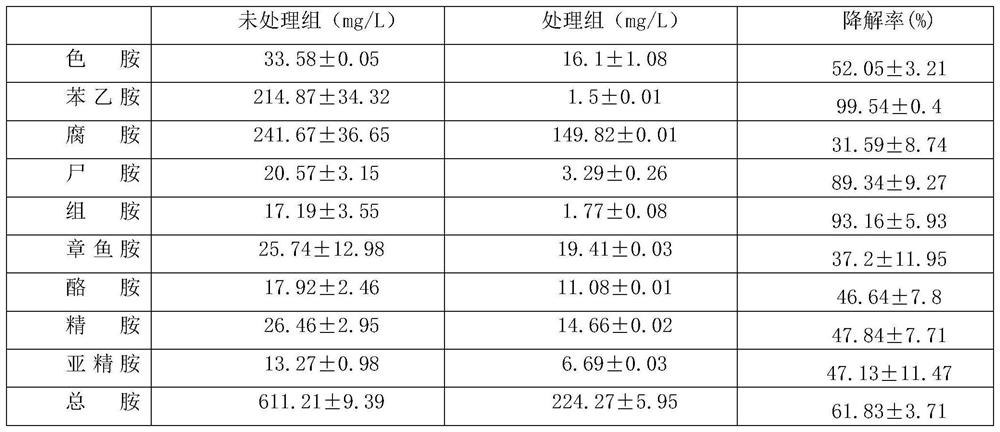

[0035] In this example, the crude amine oxidase enzyme solution extracted from peanut has obvious amine reducing effect. The results are shown in image 3 . The degradation rate of the crude enzyme extract from peanuts for phenethylamine reached 99.54%, and the degradation rate for the total amount of nine biogenic amines reached 61.83%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com