Application of Au/ZnO composite material in photoelectrochemical sensor electrode

A sensor electrode, photoelectrochemical technology, applied in the direction of material electrochemical variables, scientific instruments, analytical materials, etc., can solve the problems of potential safety hazards, difficult to achieve online detection, large equipment and other problems, to improve detection sensitivity and save detection time. , Improve the effect of photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

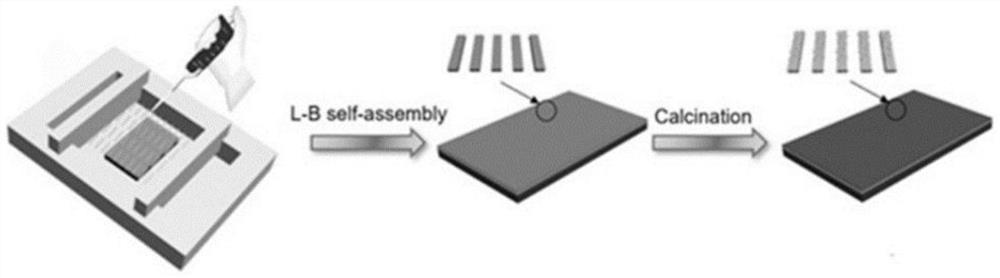

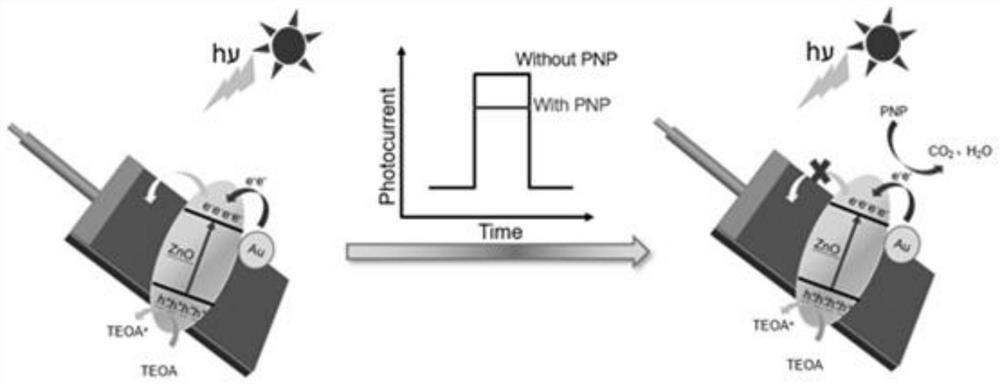

[0030] refer to figure 1 , this embodiment proposes a photoelectrochemical sensor electrode, the preparation method of which includes the following steps:

[0031] (1) in the selenium powder solution that concentration is 0.02mol / L (dissolve 0.4mmol Se powder in 20mL 80wt% hydrazine hydrate solution and obtain), drip the zinc chloride aqueous solution (0.2mmol ZnCl) that concentration is 0.01mol / L 2 Dissolved in 20 mL of ultrapure water), stirred and mixed for 1 hour, and then hydrothermally reacted at 180 ° C for 12 hours. After the end, the precipitate was washed with hydrazine hydrate centrifugation 3 times to remove excess selenium powder, and then the precipitate was centrifuged with water until neutral. Finally, the precipitate was washed twice with ethanol to remove water, yielding ZnSe 0.5N 2 H 4 nanoribbons;

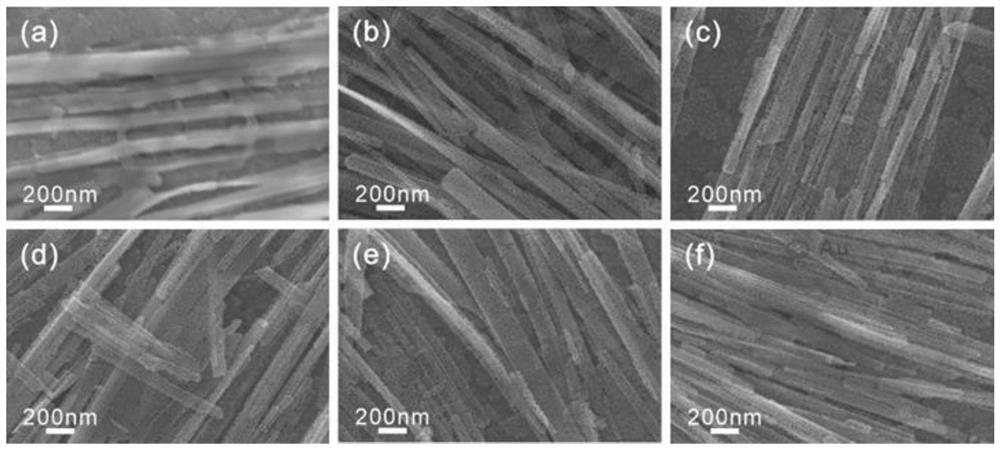

[0032] (2) 0.2mmol ZnSe·0.5N 2 H 4 The nanobelts were dissolved in 70 mL of ethanol solution, and after stirring for 10 min, 400 μL of HAuCl with a concent...

Embodiment 2

[0038] This embodiment proposes a photoelectrochemical sensor electrode, and the preparation method includes the following steps:

[0039] (1) in the selenium powder solution that concentration is 0.02mol / L (dissolve 0.4mmol Se powder in 20mL 80wt% hydrazine hydrate solution and obtain), drip the zinc chloride aqueous solution (0.2mmol ZnCl) that concentration is 0.01mol / L 2 Dissolved in 20 mL of ultrapure water), stirred and mixed for 1 hour, and then hydrothermally reacted at 180 ° C for 12 hours. After the end, the precipitate was first centrifuged with hydrazine hydrate for 3 times to remove excess selenium powder, and then the precipitate was centrifuged with water until neutral. Finally, the precipitate was washed twice with ethanol to remove water, resulting in white ZnSe 0.5N 2 H 4 nanoribbons;

[0040] (2) 0.2mmol ZnSe·0.5N 2 H 4 The nanoribbons were dissolved in 70 mL of ethanol solution, and after stirring for 10 min, 200 μL of HAuCl with a concentration of 5 mm...

Embodiment 3

[0046] This embodiment proposes a photoelectrochemical sensor electrode, and the preparation method includes the following steps:

[0047] (1) in the selenium powder solution that concentration is 0.02mol / L (dissolve 0.4mmol Se powder in 20mL 80wt% hydrazine hydrate solution and obtain), drip the zinc chloride aqueous solution (0.2mmol ZnCl) that concentration is 0.01mol / L 2 Dissolved in 20 mL of ultrapure water), stirred and mixed for 1 hour, and then hydrothermally reacted at 180 ° C for 12 hours. After the end, the precipitate was first centrifuged with hydrazine hydrate for 3 times to remove excess selenium powder, and then the precipitate was centrifuged with water until neutral. Finally, the precipitate was washed twice with ethanol to remove water, resulting in white ZnSe 0.5N 2 H 4 nanoribbons;

[0048] (2) 0.2mmol ZnSe·0.5N 2 H 4 The nanobelts were dissolved in 70 mL of ethanol solution, and after stirring for 10 min, 600 μL of HAuCl with a concentration of 5 mmol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com