Titanium-based anode and preparation method and application thereof

An anode and titanium-based technology, applied in the field of electrochemistry, can solve the problems of poor acid resistance, low life, high oxygen evolution potential, etc., and achieve the effect of saving power consumption and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

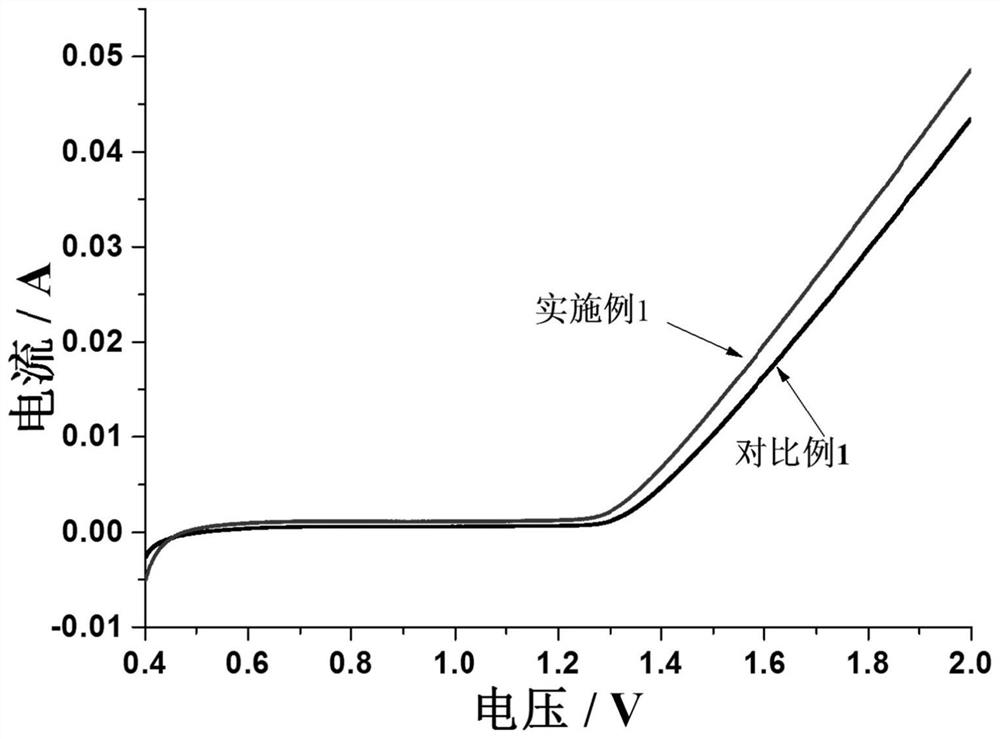

Embodiment 1

[0090] In this example, a titanium-based anode is prepared, and the specific process is as follows:

[0091] D1. Material preparation:

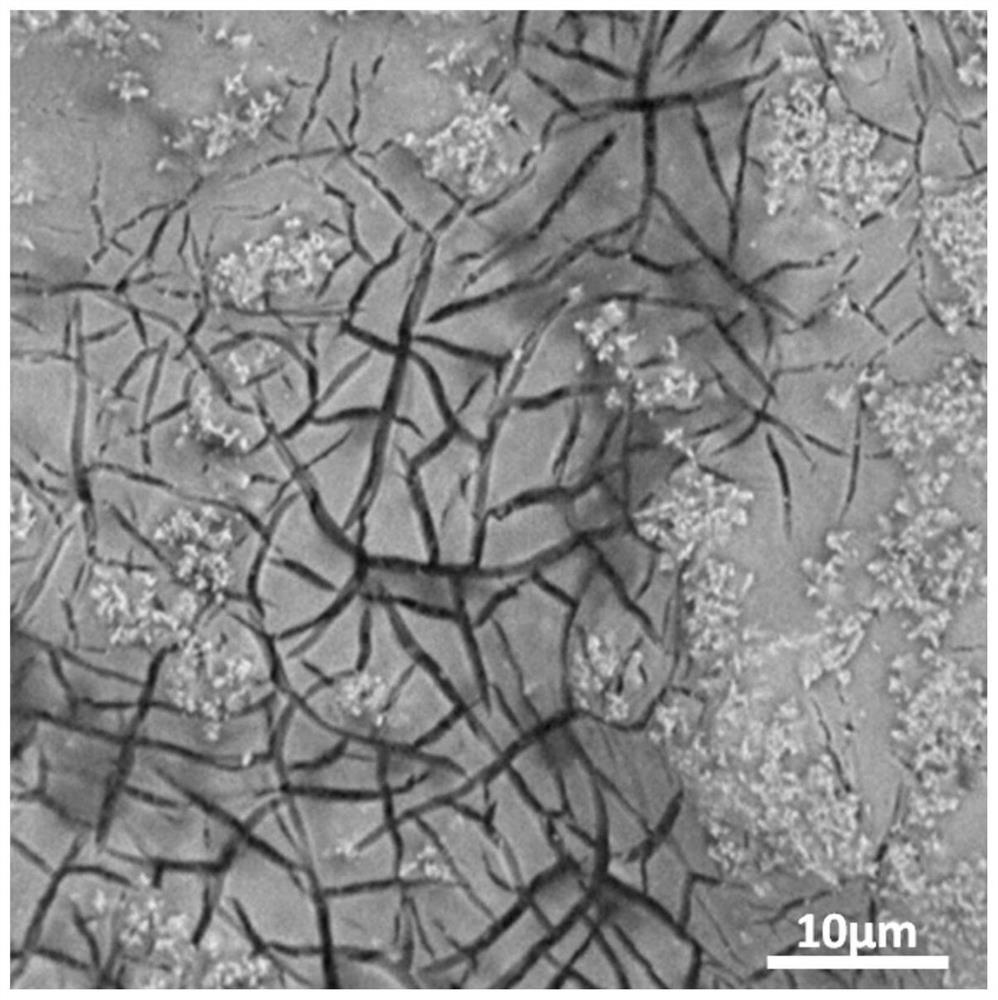

[0092] D1a. Preparation of titanium substrate: the sandblasted titanium plate (TA1 and TA2 have similar results, and TA1 is used in this example), after degreasing and oxalic acid etching treatment, a uniform rough surface is obtained, and titanium is obtained after cleaning and drying. matrix;

[0093] D1b. Preparation of coating solution:

[0094] According to the ratio of metal molar ratio Ir:Ta:Zr=68:30:2, first dissolve zirconium chloride in a mixed solvent of n-butanol and isopropanol (volume ratio 1:1), add a little hydrochloric acid to prevent hydrolysis, hydrochloric acid The mass of (12mol / L) accounts for 0.5% of the mass percentage of the mixed solvent; after shaking, ultrasonication for 20min makes it fully dissolved or dispersed; then add chloroiridic acid and tantalum chloride to it in proportion to prepare total metal ions A...

Embodiment 2

[0099] A titanium-based anode is prepared in this example, and the specific difference from Example 1 is:

[0100] In step D1b, the metal molar ratio is Ir:Ta:Sb=65:32:3, that is, no zirconium chloride is added, but a corresponding proportion of antimony chloride (the salt corresponding to Sb) is added.

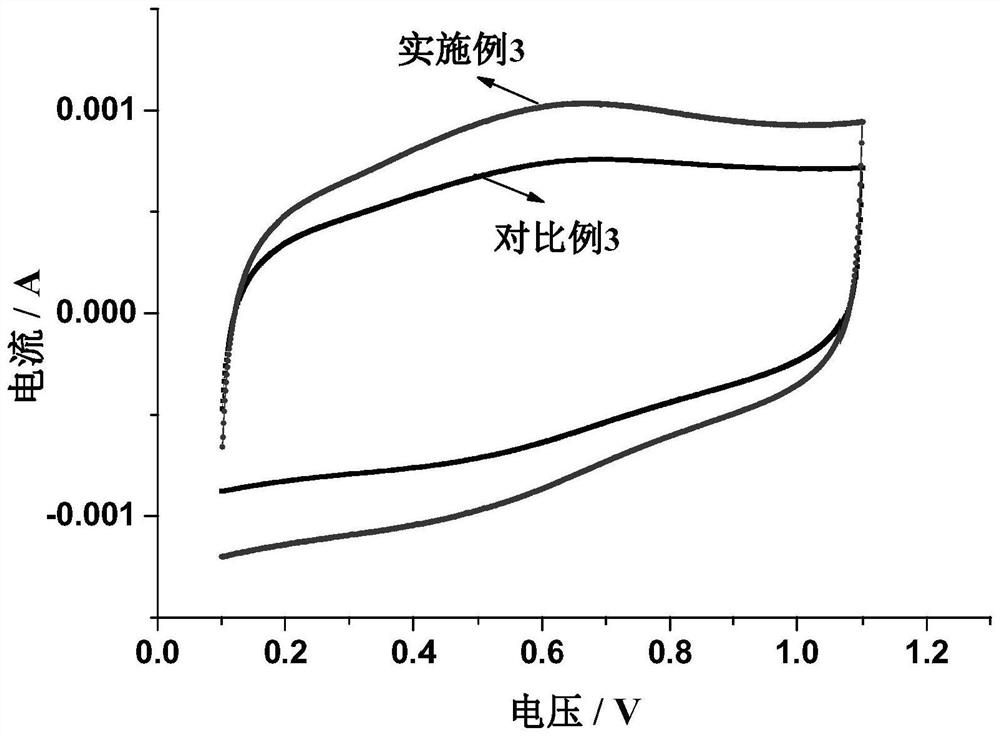

Embodiment 3

[0102] A titanium-based anode is prepared in this example, and the specific difference from Example 1 is:

[0103] In step D1b, the metal molar ratio is Ir:Ta:Sb=65:30:5, that is, no zirconium chloride is added, but a corresponding proportion of antimony chloride (the salt corresponding to Sb) is added.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com