Environment-friendly high-whiteness domestic ceramic product and preparation process thereof

A ceramic product, high white technology, applied in the field of ceramics, can solve problems such as difficulty in guaranteeing product performance indicators, narrow firing temperature range, easy deformation and brittleness of products, etc., to achieve large firing range, high yield, and enhanced flexural strength and the effect of thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

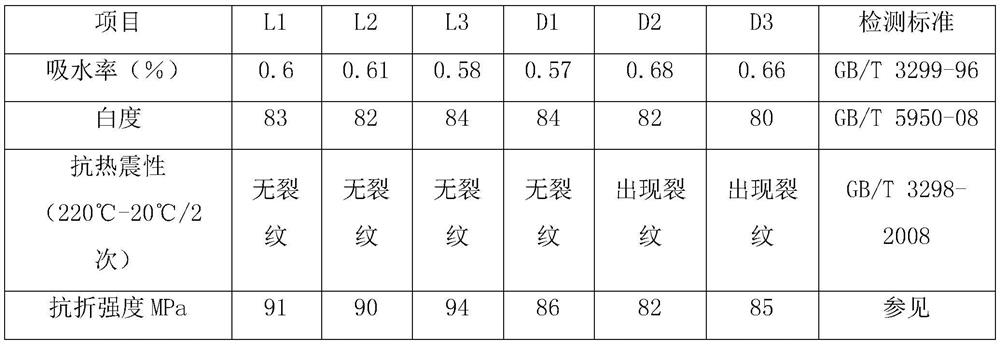

Examples

Embodiment 1

[0021] This embodiment provides an environmentally friendly high-whiteness daily-use ceramic product, including the following components in parts by weight: 30 parts of Dehua Jinzhukeng kaolin, 8 parts of albite, 3 parts of quartz, 8 parts of zirconium silicate, and 3 parts of bone ash Parts, 25 parts of composite pellets.

[0022] Among them: the composite granular material is obtained by coating fluorite tailings powder and calcined smithsonite powder with Dehua Longque red clay dispersion slurry, and then granulating and drying, with a particle size of 300 mesh. The Dehua Longque red clay dispersion slurry is The mass fraction ratio of raw material, fluorite tailings powder and calcined smithsonite powder is 30:0.8:0.2. The calcination temperature of the calcined smithsonite powder is 800° C., and the particle size is 3 μm; the particle size of the fluorite tailings powder is 3 μm.

[0023] The treatment process of the Dehua Longque red clay dispersion slurry is as follows...

Embodiment 2

[0026] This embodiment provides an environment-friendly high-whiteness daily-use ceramic product, including the following components in parts by weight: 15 parts of Dehua Jinzhukeng kaolin, 12 parts of albite, 6 parts of quartz, 6 parts of zirconium silicate, and 5 parts of bone ash Parts, 30 parts of composite pellets.

[0027] Wherein: the composite granular material is obtained by coating fluorite tailings powder and calcined smithsonite powder with Dehua Longque red clay dispersion slurry, and then granulating and drying, with a particle size of 200 mesh. The Dehua Longque red clay dispersion slurry is The mass fraction ratio of raw material, fluorite tailings powder and calcined smithsonite powder is 25:0.5:0.5. The calcination temperature of the calcined smithsonite powder is 850° C., and the particle size is 4 μm; the particle size of the fluorite tailings powder is 4 μm.

[0028] The treatment process of the Dehua Longque red clay dispersion slurry is as follows: the ...

Embodiment 3

[0031] This embodiment provides an environmentally friendly high-whiteness daily-use ceramic product, including the following components in parts by weight: 20 parts of Dehua Jinzhukeng kaolin, 10 parts of albite, 5 parts of quartz, 8 parts of zirconium silicate, and 4 parts of bone ash. Parts, 35 parts of composite pellets.

[0032] Wherein: the composite granular material is obtained by coating fluorite tailings powder and calcined smithsonite powder with Dehua Longque red clay dispersion slurry, and then granulating and drying, with a particle size of 400 mesh. The Dehua Longque red clay dispersion slurry is The mass fraction ratio of raw material, fluorite tailings powder and calcined smithsonite powder is 50:0.8:0.4. The calcination temperature of the calcined smithsonite powder is 850° C., and the particle size is 4 μm; the particle size of the fluorite tailings powder is 2.5 μm.

[0033] The treatment process of the Dehua Longque red clay dispersion slurry is as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com