Nano high-permeability seal primer emulsion and preparation method thereof

A closed primer, high penetration technology, applied in primers, coatings, etc., can solve the problem of not reaching the protective effect, meet the requirements of charge repulsion, and enhance the effect of strengthening the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

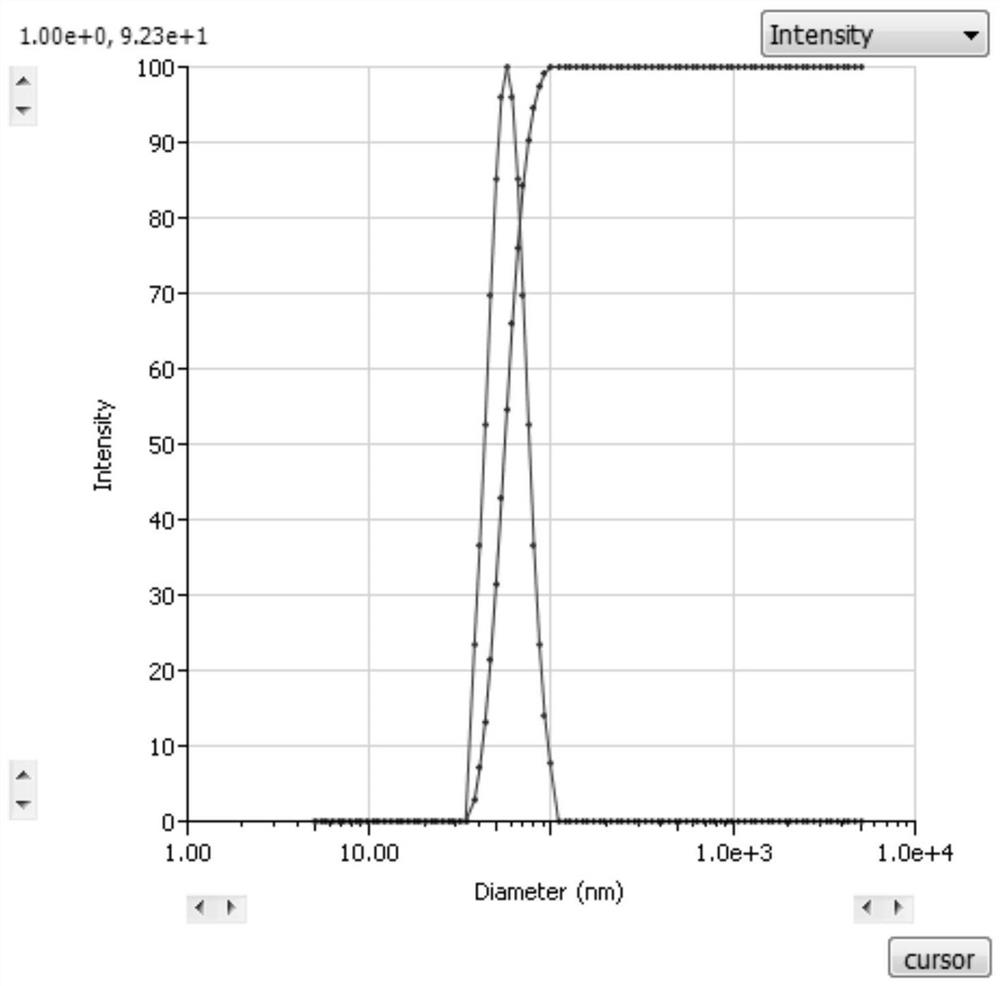

Embodiment 1

[0037] A nanometer high-permeability sealing primer emulsion, comprising the following components in parts by mass:

[0038] 60 parts of deionized water, 16 parts of methyl methacrylate, 5 parts of butyl acrylate, 15 parts of isooctyl acrylate, 8 parts of acetoacetoxy ethyl methacrylate, 2 parts of special functional monomer, alkylphenol polyoxygen 1 part of vinyl ether, 3 parts of alkylbenzene sulfonate, 1.5 parts of ammonium persulfate, and 0.5 part of ammonium bicarbonate.

[0039] The preparation method of the nanometer high-permeability sealing primer emulsion comprises the following steps:

[0040] Step1: Preprocessing

[0041] (1) Preparation of reaction primer: a certain amount of deionized water, 0.2 part of alkylphenol polyoxyethylene ether, 0.5 part of alkylbenzene sulfonate, 0.5 part of ammonium bicarbonate and 0.3 part of ammonium persulfate were dissolved and placed in In a normal pressure reactor with a thermometer and a stirrer, and at the same time, the temp...

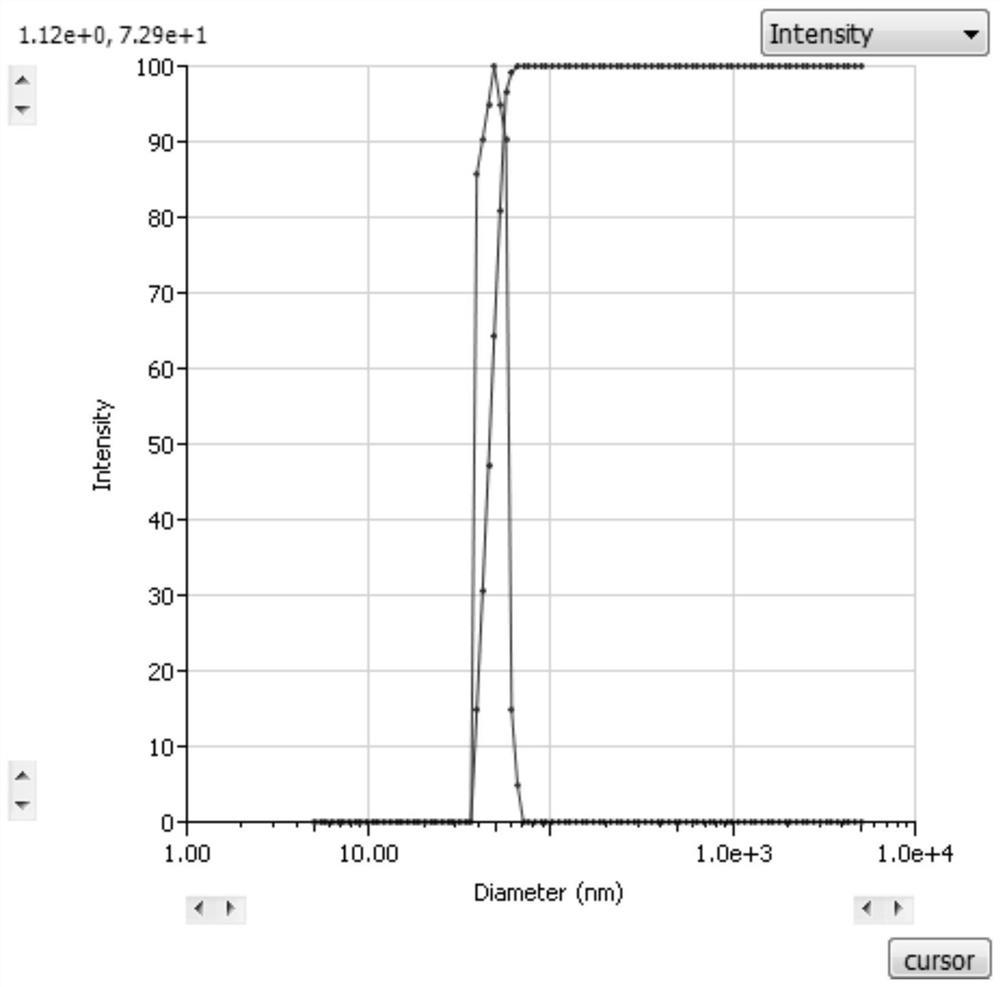

Embodiment 2

[0055] A nanometer high-permeability sealing primer emulsion, comprising the following components in parts by mass:

[0056] 90 parts of deionized water, 10 parts of styrene, 18 parts of methyl methacrylate, 5 parts of ethyl acrylate, 20 parts of isooctyl acrylate, 10 parts of vinyl triethoxysilane, 3 parts of special functional monomer, fat 2 parts of alcohol ether, 4 parts of fatty alcohol polyoxyethylene ether sulfate salt, 2 parts of potassium persulfate and 1 part of sodium bicarbonate.

[0057] The preparation method of the nanometer high-permeability sealing primer emulsion comprises the following steps:

[0058] Step1: Preprocessing

[0059] (1) Preparation of reaction primer: a certain amount of deionized water, 0.3 part of fatty alcohol ether, 0.6 part of fatty alcohol polyoxyethylene ether sulfate salt, 1 part of sodium bicarbonate and 0.5 part of potassium persulfate are dissolved and placed on a belt In a normal pressure reactor with a thermometer and a stirrer,...

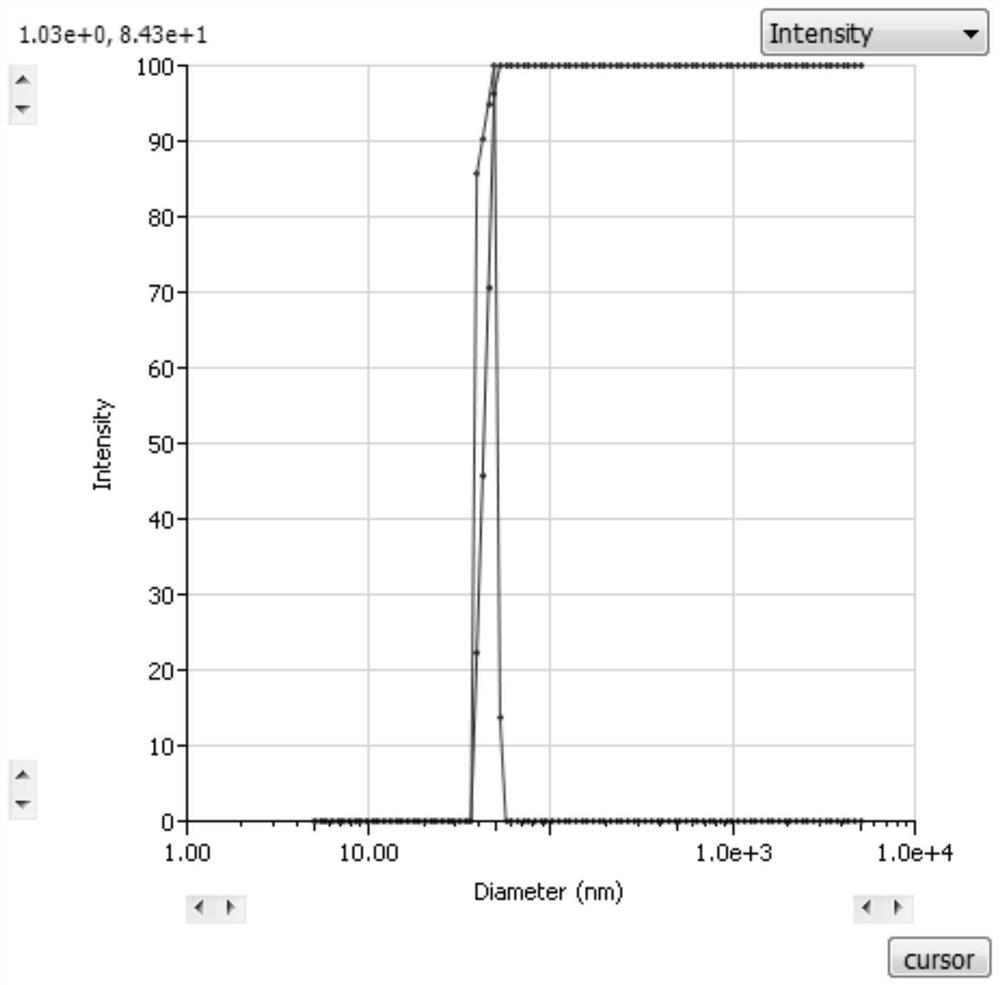

Embodiment 3

[0073] A nanometer high-permeability sealing primer emulsion, comprising the following components in parts by mass:

[0074] 75 parts of deionized water, 25 parts of styrene, 30 parts of isooctyl acrylate, 16 parts of N-methylol acrylamide, 4 parts of special functional monomers, 6 parts of succinate sulfonate, 1 part of ammonium persulfate, 0.5 part of sodium carbonate.

[0075] The preparation method of the nanometer high-permeability sealing primer emulsion comprises the following steps:

[0076] Step1: Preprocessing

[0077] (1) Preparation of reaction base material: a certain amount of deionized water, 1 part of succinate sulfonate, 0.5 part of sodium carbonate and 0.4 part of ammonium persulfate are dissolved and placed in a normal pressure reactor with a thermometer and agitator at the same time, the temperature of the reaction system was raised to about 82 ° C, and the stirring speed was 100-200 rpm / min;

[0078] (2) Preparation of mixed additive I: put the remainin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com