Anti-scale agent suitable for high-salt and high-chlorine working conditions and preparation method thereof

A scale inhibitor, high chlorine technology, applied in chemical instruments and methods, scale removal and water softening, polluted groundwater/leachate treatment, etc. There are no problems such as research on anti-scaling and anti-scaling properties to achieve a good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of a scale inhibitor suitable for high-salt and high-chlorine working conditions, including the following:

[0041] The maleic acid is added to the reaction flask according to the weight percentage, the water is added and the temperature is heated to dissolve, and the Methylidene phosphoric acid, the sodium hydroxyethylidene diphosphate, the gluconate, the polyaspartic acid or the polyepoxysuccinic acid are reacted at 70°C to 100°C, and after cooling, they are suitable for high salt Anti-scaling agent under high chlorine conditions.

[0042] The provided preparation method has the following technical effects:

[0043] The method is relatively simple, and the reaction temperature is limited, so that the various components can achieve better synergy.

[0044] Further, the reaction is carried out at a temperature of 80°C to 100°C.

[0045] Preferably, the reaction is carried out at a temperature of 90°C.

[0046]...

Embodiment A

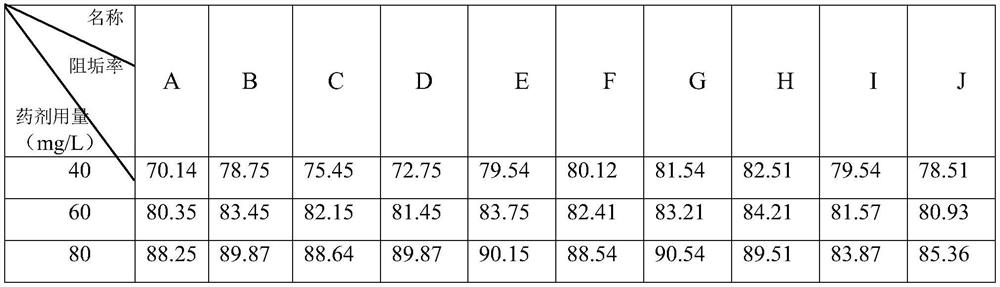

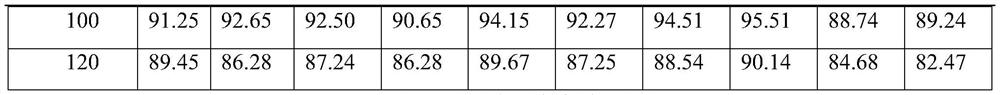

[0047] Specifically, see the following table Examples A-J:

[0048]

[0049] Table 1: The weight percent example and reaction temperature of each single agent pure product for preparing the antifouling agent

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com