Anti-protein structure catalyst particle for catalytic oxidation of methane and preparation method of anti-protein structure catalyst particle

A technology of anti-protein structure and catalyst particles, which is applied in the field of anti-protein structure catalyst particles and its preparation, can solve the problems of high economic cost and danger, achieve high flow rate, easy recovery, and reduce the effect of material diffusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

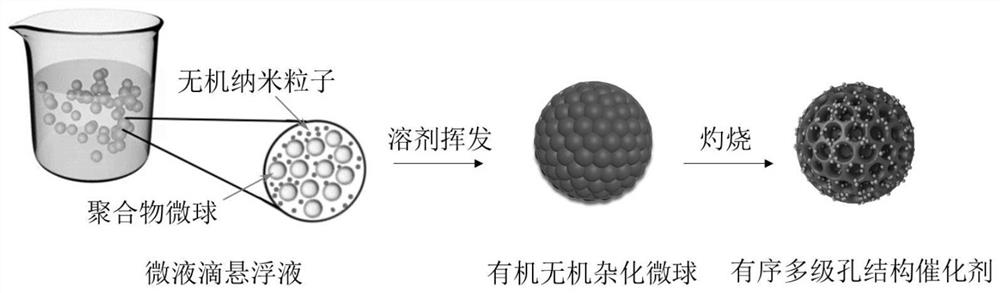

[0024] The inverse protein structure catalyst particles for catalytic oxidation of methane of the present invention, the preparation method comprises:

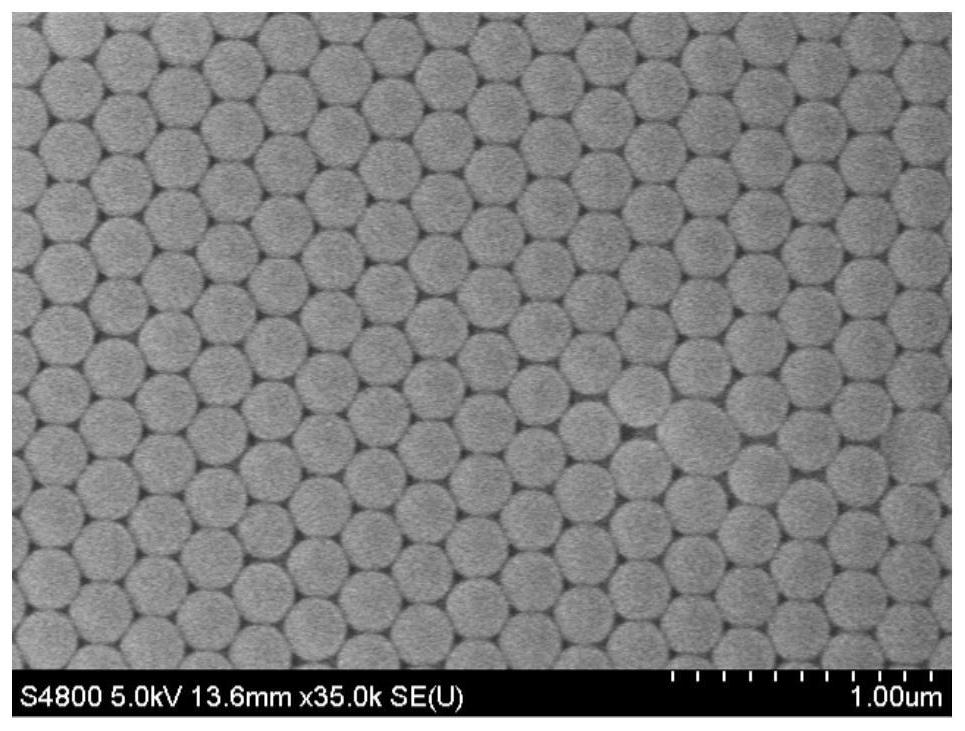

[0025] (1) adopting emulsion polymerization to prepare PS (polystyrene) microspheres with a particle size of 200 nm (the coefficient of variation in particle size is less than 5%), and the obtained PS microspheres are lyophilized and stored;

[0026] (2) Weigh 0.3g PS microspheres, 0.1g SiO 2 Nanoparticles (particle size 5nm), 0.31g lanthanum nitrate (0.95mmol), 0.34g manganese nitrate (1.90mmol), 0.21g strontium nitrate (0.99mmol) were dispersed and dissolved in 2mL ethylene glycol, 2mL methanol and 6mL deionized water. In the mixed solvent, mixed solution A was obtained; mixed solution A was used as the dispersed phase, and the fluorine oil reagent was used as the continuous phase, and the microfluidic emulsification method was used to prepare monodisperse microdroplets. The size of the microdroplets can be adjusted by adjus...

Embodiment 2

[0030] On the basis of Example 1, Pd nanoparticles were also introduced on the surface of the prepared inverse opal catalyst particles A; the specific steps were as follows:

[0031] (1) and (2) are the same as in Example 1;

[0032] (3) Take 0.45g PdCl 2 , 0.30g polyvinyl alcohol (molecular weight is 10 4 g / mol) was dispersed and dissolved in 10 mL of deionized water to obtain mixed solution B; 1 g of catalyst particles A and 3 g of NaBH were sequentially added to mixed solution B under the conditions of an ice bath and nitrogen injection. 4 , the reaction is 30min;

[0033] (4) Suction filtration of the product obtained in step (3) with a Buchner funnel, and washing with a large amount of deionized water; drying in an oven at 80 ° C after washing;

[0034] (5) calcining the dried product obtained in step (4) in an air atmosphere (calcination conditions are: 500° C., 3 h) to obtain hierarchically porous Pd / SiO 2 -La 0.5 Sr 0.5 MnO 3 Inverse Opal Catalyst Particles B. ...

Embodiment 3

[0037] On the basis of Example 1, Au nanoparticles were also introduced on the surface of the prepared inverse opal catalyst particles A to further improve the catalytic performance, and the specific steps were as follows:

[0038] (1) and (2) are the same as in Example 1.

[0039] (3) Take A1 g of inverse opal catalyst particles, drop 0.3 mL of 1 mol / L gold acetate solution on the surface, and store in the dark for 30 minutes, the gold acetate will penetrate into the voids of the inverse opal; UV light for 30min to make Au + Reduction to elemental Au to obtain Au / TiO 2 -La 0.5 Sr 0.5 MnO 3 Anti-Protein Catalyst Particles C.

[0040] The experimental procedure of catalyst activity is the same as that in Example 1.

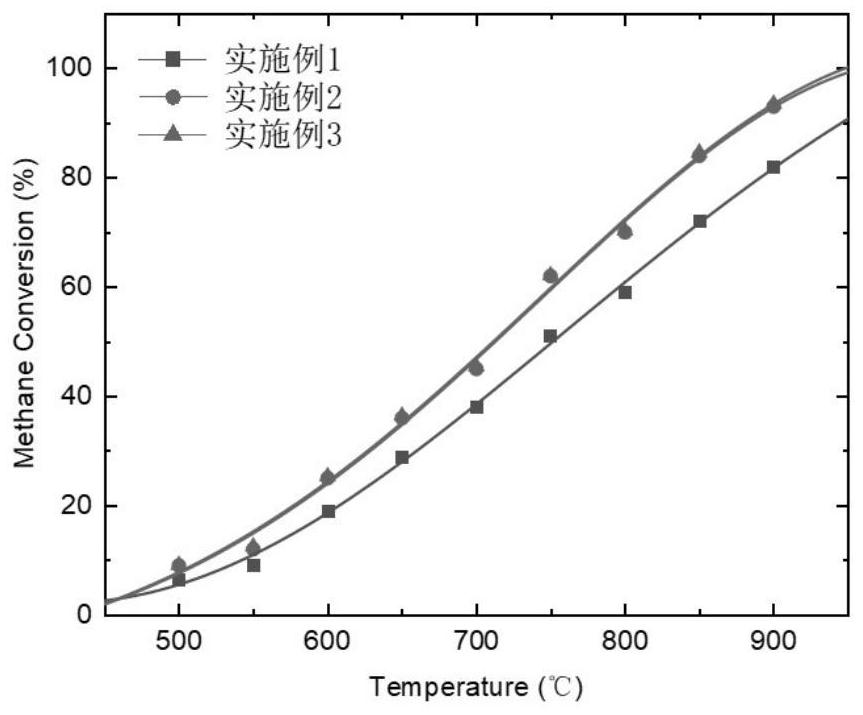

[0041] The catalytic activity data of the inverse protein structure catalyst particles of Examples 1-3 are as follows: image 3 As can be seen from the figure, the catalysts loaded with Pd and Au precious metals have almost the same catalytic oxidation perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap