Boron adsorption resin as well as preparation method and application thereof

A technology for adsorbing resins and cross-linking agents, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc. Contamination and service life, improved boron adsorption capacity, and easy mass production effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

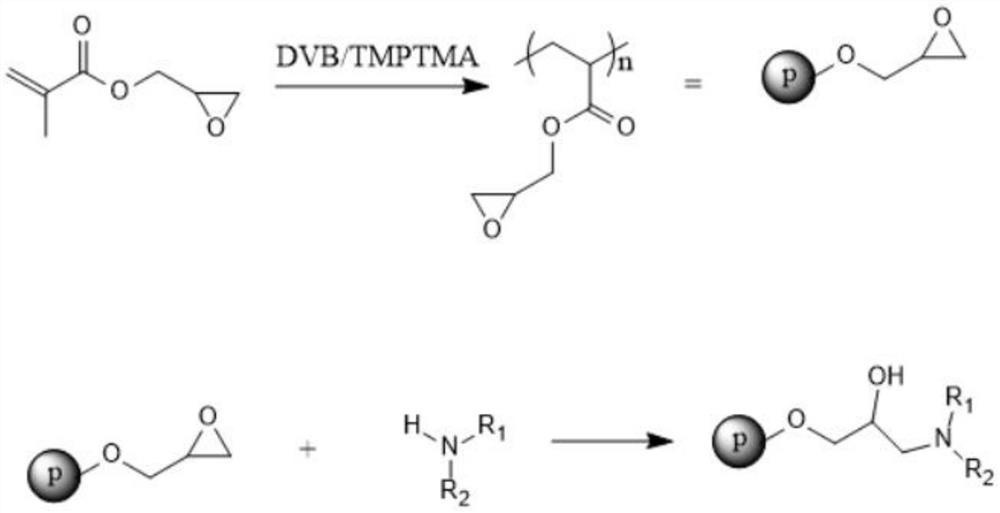

[0028] The preparation method of the boron adsorption resin of the present invention, the steps are as follows:

[0029] 1) After mixing the oil phase composed of glycidyl methacrylate (GMA), crosslinking agent, porogen, and benzoyl peroxide uniformly, disperse by stirring in brine containing dispersant, and then heat to 55-65 ℃, after holding for 2-3 hours, continue to heat up to 70-80 ℃, holding for 3-6 hours to obtain a reaction solution containing copolymerized beads, separate the copolymerized beads from the reaction solution, and then purify for use.

[0030] Among them, the mass of the cross-linking agent accounts for 10%-20% of the mass of GMA, the mass of the porogen is 30%-80% of the total mass of GMA and the cross-linking agent, and the mass of benzoyl peroxide is the mass of GMA and the cross-linking agent. 0.5%-1% of the total mass, and the mass of the dispersant is 1%-5% of the salt water mass.

[0031] 2) subjecting the purified copolymer beads to a hydrotherma...

Embodiment 1

[0042] 1) Mix the oil phase composed of 142.0g glycidyl methacrylate (GMA), 23.4g trimethylolpropane trimethacrylate (TMPTMA), 91.0g xylene and 2.0g benzoyl peroxide evenly Then, it was dispersed in 1200 ml of saline containing 60.0 g of 5% hydroxyethyl cellulose dispersant by stirring, and then heated to 60 °C, kept at 70 °C for 2 hours, and kept at 70 °C for 6 hours to obtain a bead containing copolymer beads. In the reaction solution, the copolymerized beads are separated from the reaction solution, and after the copolymerized beads are washed with water, they are extracted through a column with methylal to remove the porogen, and the purification is completed.

[0043] 2) carrying out the hydrothermal epoxy ring-opening reaction process to the purified copolymer beads as follows:

[0044] Add 20.0 g of purified copolymer beads to 60.0 g of deionized water and 20.0 g of tris(hydroxymethyl)aminomethane, stir at room temperature for 2 hours and mix well, then transfer to a hy...

Embodiment 2

[0047] 1) After mixing the oil phase composed of 142.0g glycidyl methacrylate (GMA), 21.5g trimethylolpropane trimethacrylate (TMPTMA), 50.0g toluene and 1.6g benzoyl peroxide evenly , dispersed by stirring in 1200ml of saline containing 60.0g 5% hydroxyethyl cellulose dispersant, then heated to 60°C, kept at 75°C for 2 hours, and kept at 75°C for 6 hours to obtain a reaction containing copolymer beads The copolymerized beads were separated from the reaction solution, washed with water, and then extracted through a column with methylal to remove the porogen, and the purification was completed.

[0048] 2) carrying out the hydrothermal epoxy ring-opening reaction process to the purified copolymer beads as follows:

[0049] 20.0 g of the purified copolymer beads were added to 80.0 g of deionized water and 18.0 g of tris(hydroxymethyl)aminomethane, stirred at room temperature for 2 hours and mixed well, and then transferred to a hydrothermal reactor lined with tetrafluoroethylene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com