Ceramic fiber filter tube catalyst and step-by-step preparation method thereof

A ceramic fiber and catalyst technology, which is applied in the field of ceramic fiber filter tube catalyst and its step-by-step preparation, can solve the problems of weak bonding and poor denitrification activity of ceramic tube catalyst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] As mentioned above, the first aspect of the present invention provides a step-by-step preparation method of a ceramic fiber filter tube catalyst, the method comprising:

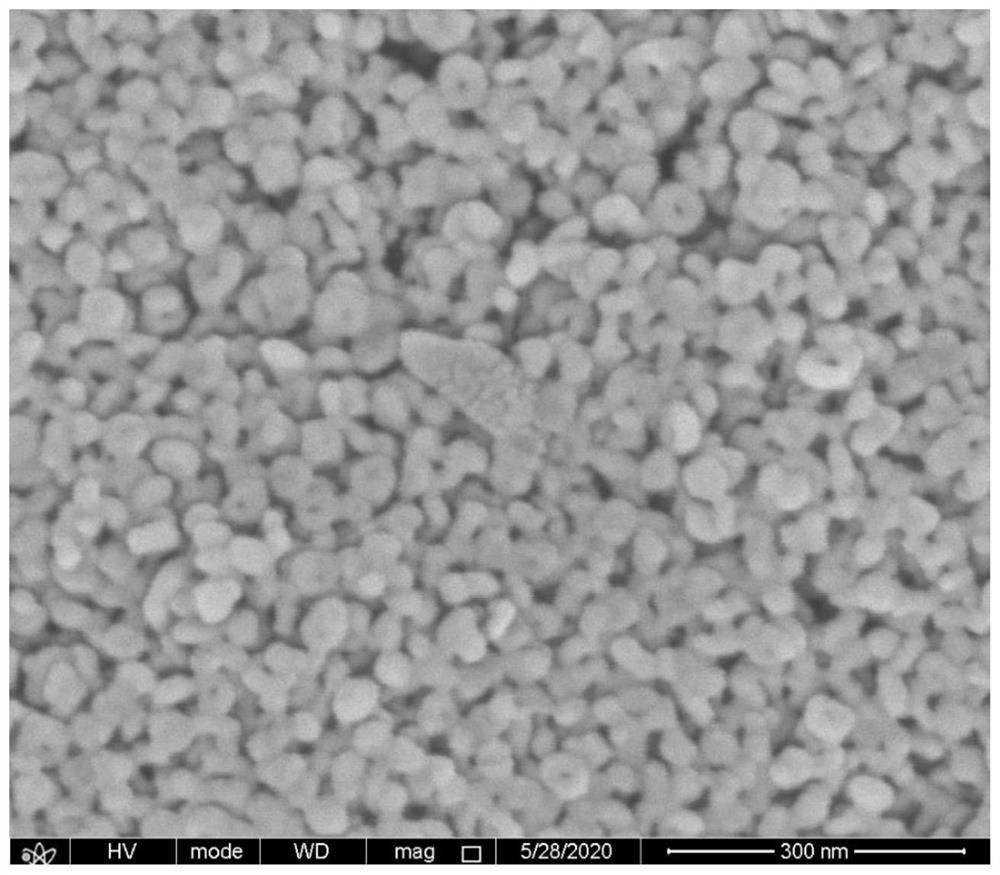

[0016] (1) adopt the solution containing inorganic titanium source to carry out the first impregnation to the ceramic fiber filter tube, then through the first drying and the first roasting, obtain the first ceramic fiber filter tube loaded with large particle titanium dioxide;

[0017] (2) using the solution containing surfactant to carry out the second impregnation to the first ceramic fiber filter tube, and then through the second drying to obtain the modified ceramic fiber filter tube;

[0018] (3) The modified ceramic fiber filter tube is subjected to the third impregnation with a solution containing an organic titanium source, and then subjected to the third drying and the second roasting to obtain a second ceramic fiber loaded with large-particle titanium dioxide and small-particle titanium dioxi...

specific Embodiment approach

[0047] According to a specific embodiment of the present invention, the molybdenum source is selected from at least one of ammonium molybdate, ammonium dimolybdate, ammonium tetramolybdate, molybdenum nitrate, molybdenum chloride and molybdenum sulfate.

[0048] According to a specific embodiment of the present invention, the tungsten source is selected from at least one of ammonium tungstate, ammonium metatungstate, ammonium paratungstate, tungsten nitrate, tungsten chloride and tungsten sulfate.

[0049] According to a specific embodiment of the present invention, the cerium source is selected from at least one of cerium chloride, cerium nitrate, cerium ammonium nitrate and cerium sulfate.

Embodiment approach

[0050] According to a specific embodiment of the present invention, the iron source is selected from at least one of ferric nitrate, ferric chloride and ferric sulfate.

[0051] According to a specific embodiment of the present invention, the niobium source is selected from at least one of niobium oxalate, niobium nitrate and niobium acetate.

[0052] According to a specific embodiment of the present invention, the nickel source is nickel sulfate and / or nickel chloride.

[0053] According to a specific embodiment of the present invention, the cobalt source is selected from at least one of cobalt sulfate, cobalt chloride and cobalt nitrate.

[0054] In some embodiments of the present invention, preferably, the conditions of the first impregnation, the second impregnation, the third impregnation and the fourth impregnation include: the degree of vacuum is 1-50kPa, preferably 5-30kPa; the time is 0.5- 24h, preferably 1-3h.

[0055] Preferably, the conditions for the first dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com