Method for preparing isopropanol through biological hydrogenation of acetone

A technology for preparing isopropanol and hydrogen, which is applied in the biological field, can solve the problems such as the yield of isopropanol needs to be further improved, and the metabolic flux of butanol is reduced, so as to reduce the metabolic flux of butanol, improve the yield and selectivity, and improve the yield. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

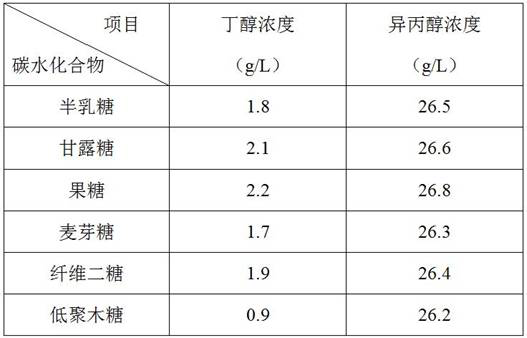

Examples

preparation example Construction

[0023] The preparation method of the soybean meal hydrolyzate comprises: weighing an appropriate amount of soybean meal, adding 5 times the mass of water, and mixing evenly. Add concentrated sulfuric acid with a mass concentration of 98% according to 2% of the volume of water, mix quickly and evenly, and do not cause partial carbonization of the material. Steam was introduced to raise the temperature of the material to 100° C., and the temperature was maintained for 20 hours, during which time the mixture was stirred for 5 minutes every 1 hour. After the hydrolysis, the soybean meal hydrolyzed liquid with red sauce and fruity aroma is obtained.

[0024] In the embodiment of the present invention, the products and by-products in the fermentation broth are analyzed by a liquid chromatograph to calculate the concentration of the main components: a liquid chromatograph (Agilent 1200), the chromatographic column is Biole HPX-87H (300mm×7.8mm) ), the mobile phase is 0.005mol / L H 2...

Embodiment 1

[0027] Nutrient solution ingredients: soybean meal hydrolyzate 10g / L, ammonium sulfate 0.9 g / L, sodium chloride 0.5 g / L, ferric sulfate 0.1 g / L, magnesium sulfate 0.3 g / L, calcium chloride 0.1 g / L, diphosphate Potassium hydrogen 1g / L, disodium hydrogen phosphate 2 g / L, p-aminobenzoic acid 0.04g / L, vitamin B1 0.04 g / L and biotin 0.004g / L, pH 7.0, sterilize at 121°C for 30min, set aside .

[0028] The seed medium is prepared by adding xylose to the nutrient solution, and the solid medium is prepared by adding 1wt% agar to the seed medium. .

[0029] Preparation of Clostridium beijerinckii XH0906 seed solution: including strain activation and seed culture, strain activation is: inoculate Clostridium beijerinckii into solid medium, and cultivate under anaerobic conditions at 28-42°C for 12-48h; Cultivation is as follows: inoculate 10% of the activated bacterial ammonia into the seed medium, and under facultative oxygen conditions, stand at 28-42 °C for 12-48 hours to obtain the ...

Embodiment 2

[0034] Same as Example 1, the difference is that: the nitrogen source adopts peptone and beef extract, each 5g / L. After testing, the butanol concentration in the product was 1.3g / L, and the isopropanol concentration was 27.1g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com