Kit for purification pretreatment of mycotoxins in grains and/or grain and oil and use method of kit

A technology of mycotoxins and kits, which is applied in the field of pretreatment of mycotoxins purification in grains and/or grains and oils, can solve the problems of time-consuming and labor-intensive automatic pre-treatment technology, time-consuming 30 minutes, organic waste liquid pollution, etc. Large-scale production application, avoiding organic waste liquid, and the effect of less manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Preparation of Mycotoxin Immunomagnetic Beads

[0048] (1) Dissolve recombinant protein G with pH=6.0, 100 mM MES buffer to obtain a recombinant protein G solution with a concentration of 10 mg / mL.

[0049] (2) Take 4 mL of NHS magnetic beads (20% (v:v), 10-30 μm), and wash the magnetic beads twice with absolute ethanol. According to the coupling ratio of 6 mg of recombinant protein G to 1 mL of NHS magnetic beads, the recombinant protein G solution was added to the NHS magnetic beads, and then a certain amount of MES buffer was supplemented, so that the whole system was carried out in the MES buffer, at room temperature, slowly Mix and incubate for 2 hours.

[0050] (3) After the incubation, the magnetic beads were washed with 0.1% PBST and PBS solution twice, and the volume was adjusted with PBS solution to prepare recombinant protein G immunomagnetic beads.

[0051] (4) Dilute the fumonisin antibody with MES buffer to prepare a fumonisin antibody dilution. Accordi...

Embodiment 2-6

[0055] The same as Example 1, the difference is only that the fumonisin antibody in step (4) is replaced by aflatoxin antibody, zearalenone antibody, vomitoxin antibody, and fumonisin antibody, respectively, to obtain aflatoxin immunity. Magnetic beads, zearalenone immunomagnetic beads, vomitoxin immunomagnetic beads, fumonisin immunomagnetic beads.

Embodiment 7

[0057] 1) Provide a kit for aflatoxin purification pretreatment and a method of using the same

[0058] The kit includes sample well 1 , reaction well 2 , cleaning wells (first cleaning wells 3 and 4 and second cleaning wells 5 ), elution wells 6 and magnetic bead storage wells 7 .

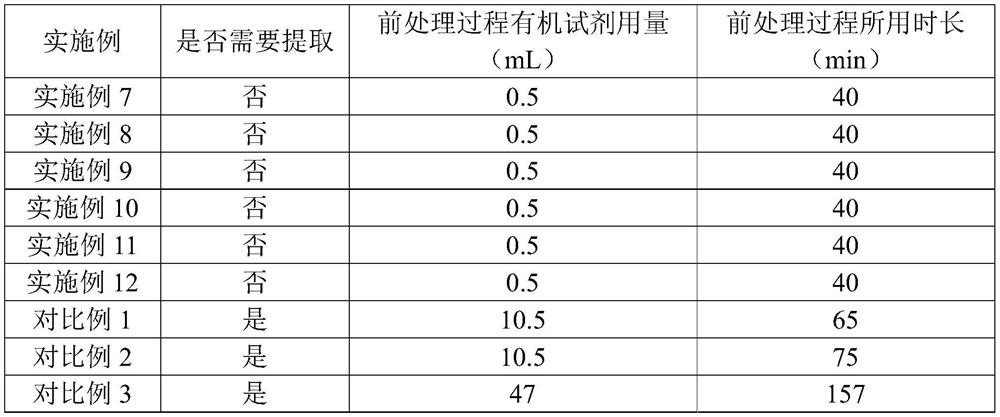

[0059] Take 50 μL of the uniformly mixed aflatoxin immunomagnetic bead solution prepared in Example 2, 0.25 mL of peanut oil quality control sample, and 0.45 mL of 0.5% PBST buffer (containing 0.5% Tween-20) and place them in reaction well 2 of the kit; Take 1 mL of 0.5% PBST buffer (containing 0.5% Tween-20) in the first washing well 3 and the first washing well 4, take 1 mL of PBS solution in the second washing well 5; take 0.5 mL of methanol in the elution well 6 middle. Take 0.5 mL of deionized water into the magnetic bead storage well 7.

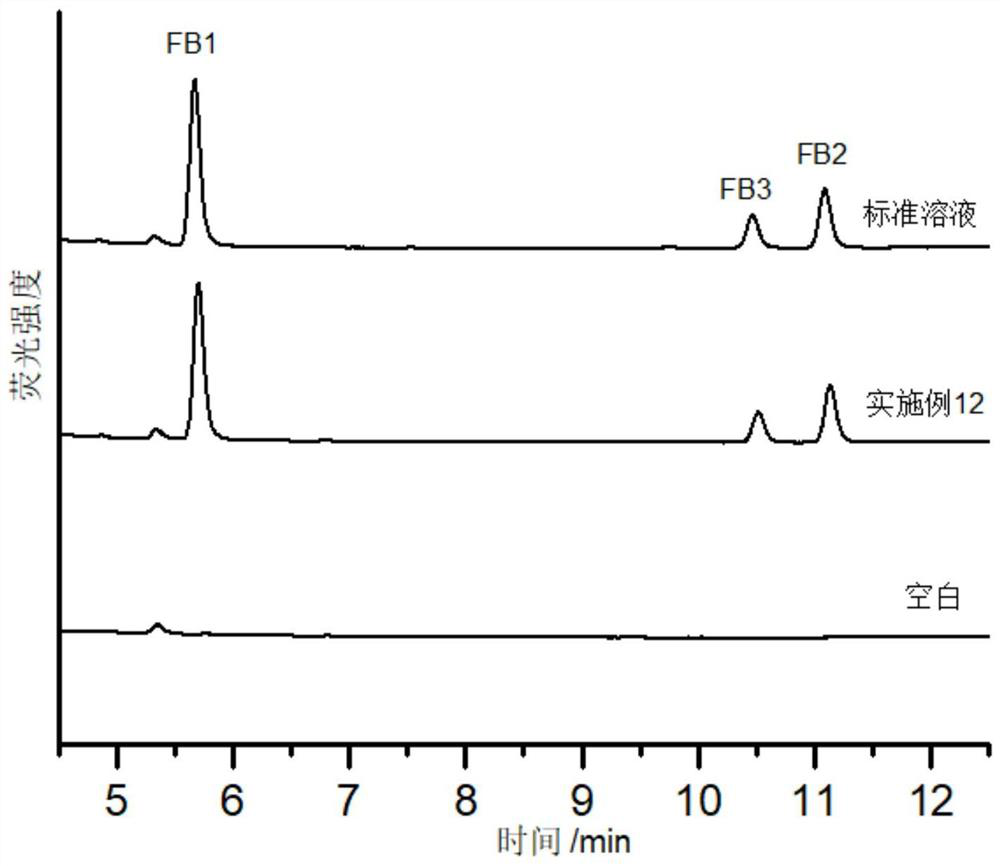

[0060] Place the kit in an automatic mycotoxin purifier. Install the magnetic rod cover on the automatic mycotoxin purifier. A fully automatic purifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com