Method for preparing high-efficiency flexible perovskite solar cell through buried interface treatment

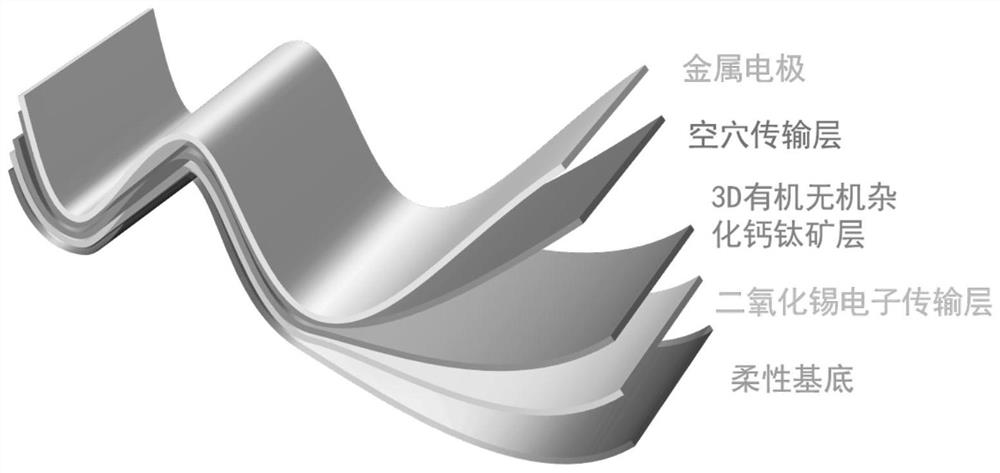

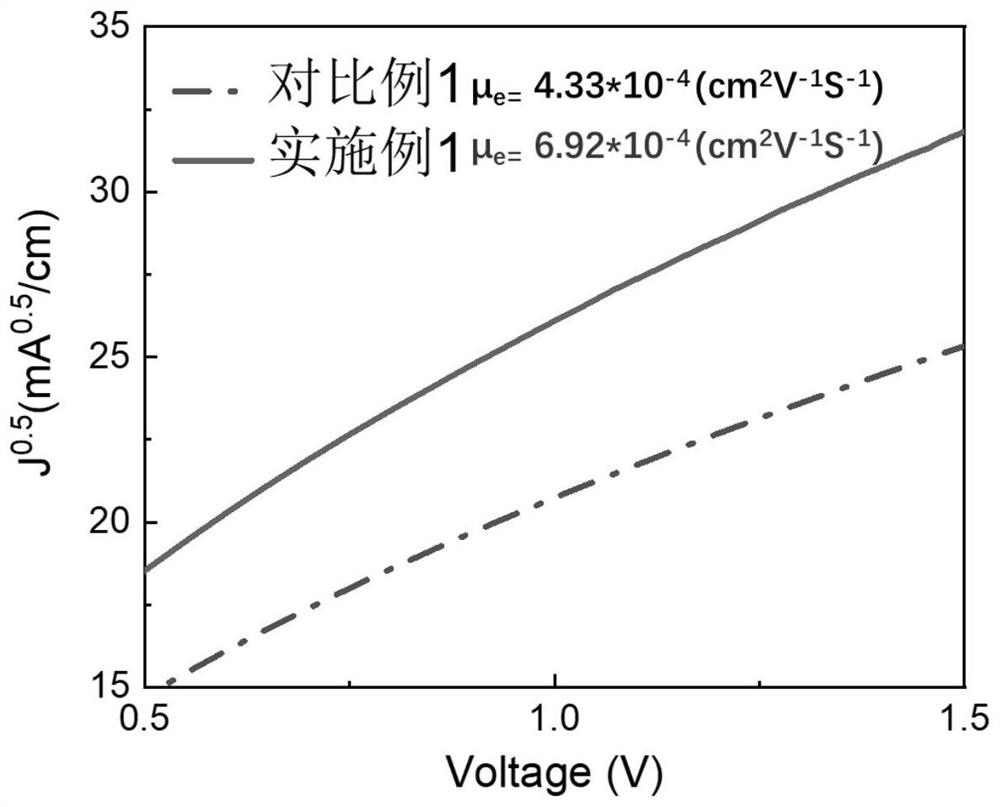

A solar cell and perovskite technology, applied in the field of solar cells, can solve the problems of perovskite film quality not as good as rigidity, poor ability of flexible substrate to block water and oxygen, and increase of defect state density, so as to reduce oxygen vacancy defects and increase Electron mobility and the effect of reducing the density of defect states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment proposes a method for preparing a tin dioxide electron transport layer by a buried bottom interface treatment, which specifically includes the following steps:

[0032] Step 1. Cleaning the flexible substrate: Choose a composite flexible material of polyethylene terephthalate (PEN) and indium tin oxide (ITO) as the flexible substrate, rinse with deionized water, and then use the rinsed flexible substrate in turn. Deionized water, acetone, and absolute ethanol were ultrasonically treated for 10 minutes at room temperature; the ultrasonically treated flexible substrate was blown dry with nitrogen, and the flexible substrate was fixed on the hard glass with high-temperature double-sided tape, and then plasma was used. Body treatment to enhance bonding and adhesion of flexible substrate surfaces.

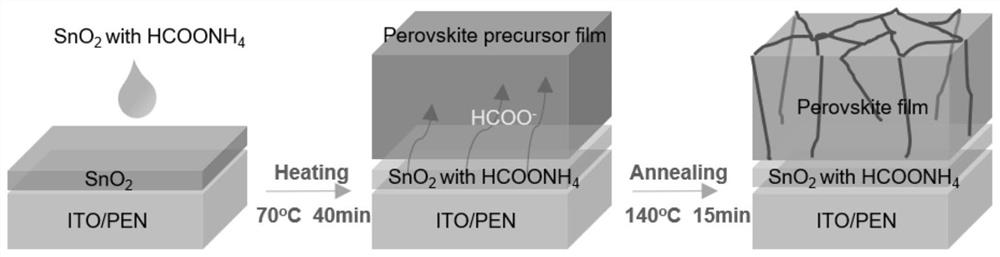

[0033] Step 2. Preparation of tin dioxide electron transport layer:

[0034] Step 2.1. Mix the 15% tin dioxide colloid aqueous solution with deionized water in a...

Embodiment 2

[0037] This embodiment proposes a method for preparing a high-efficiency flexible perovskite solar cell by a buried bottom interface treatment, which specifically includes the following steps:

[0038] Step 1. Clean the flexible substrate: choose a composite flexible material of polyethylene terephthalate (PEN) and indium tin oxide (ITO) as the flexible substrate, rinse with deionized water, and then use the rinsed flexible substrate in turn. Deionized water, acetone, and anhydrous ethanol were ultrasonically treated, each at room temperature for 10 min, and the ultrasonically treated flexible substrate was blown dry with nitrogen.

[0039] Step 2. Cut the glass to 2*2cm through the glass cutting table 2 The size of the glass will be used as a fixed substrate. After cutting, the cut glass will be cleaned by an ultrasonic cleaning machine to prevent residual glass dross and organic attachments from damaging and polluting the flexible substrate to be fixed; then cut the flexible...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com