Single-crystal type multi-element positive electrode material as well as preparation method and application thereof

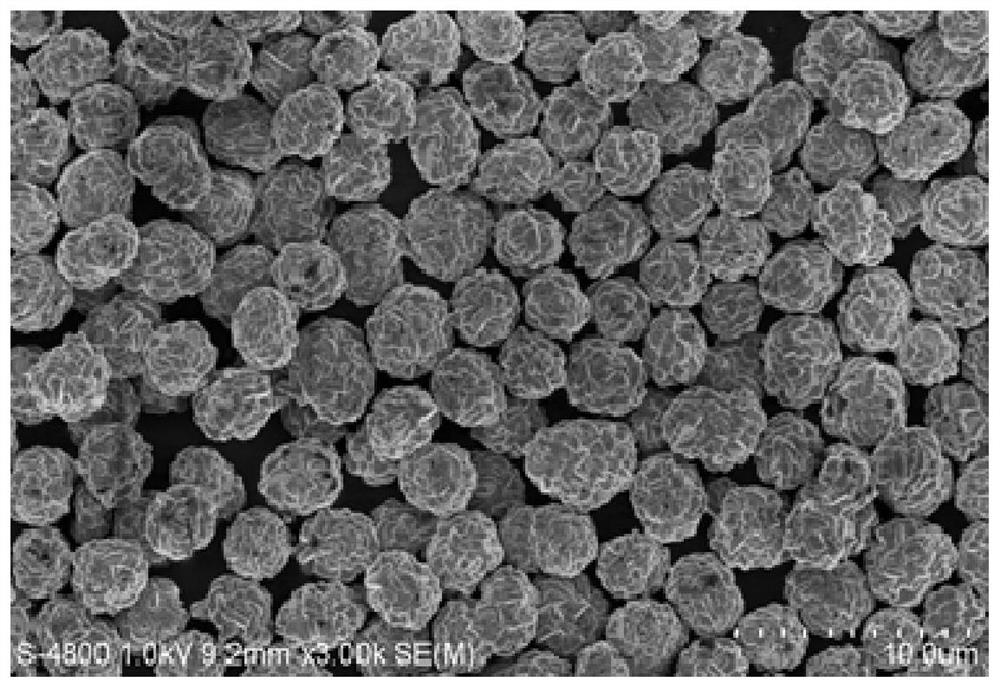

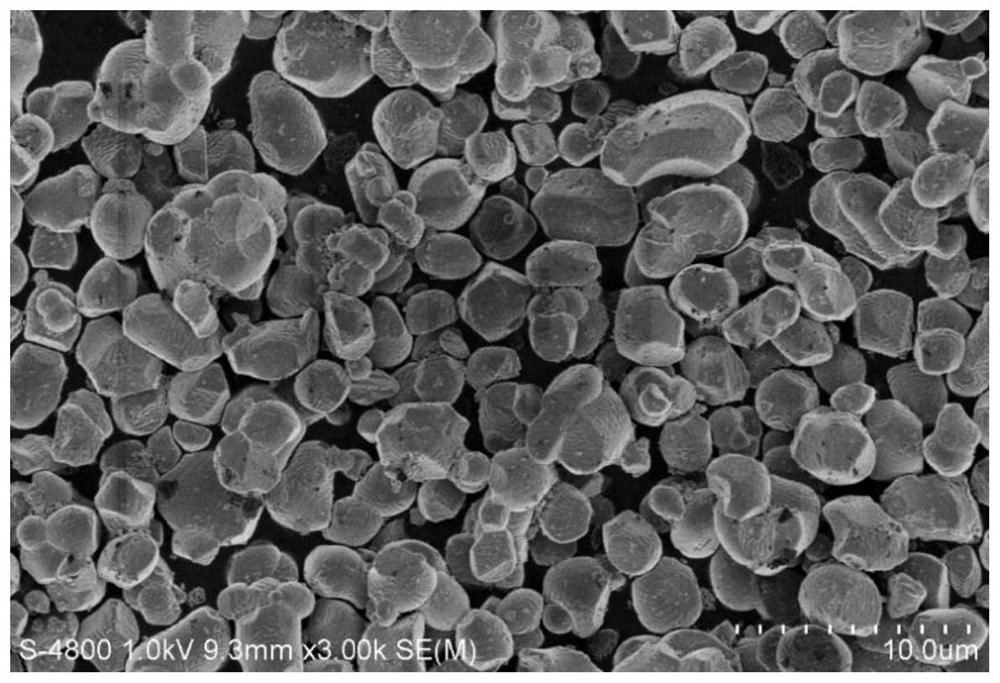

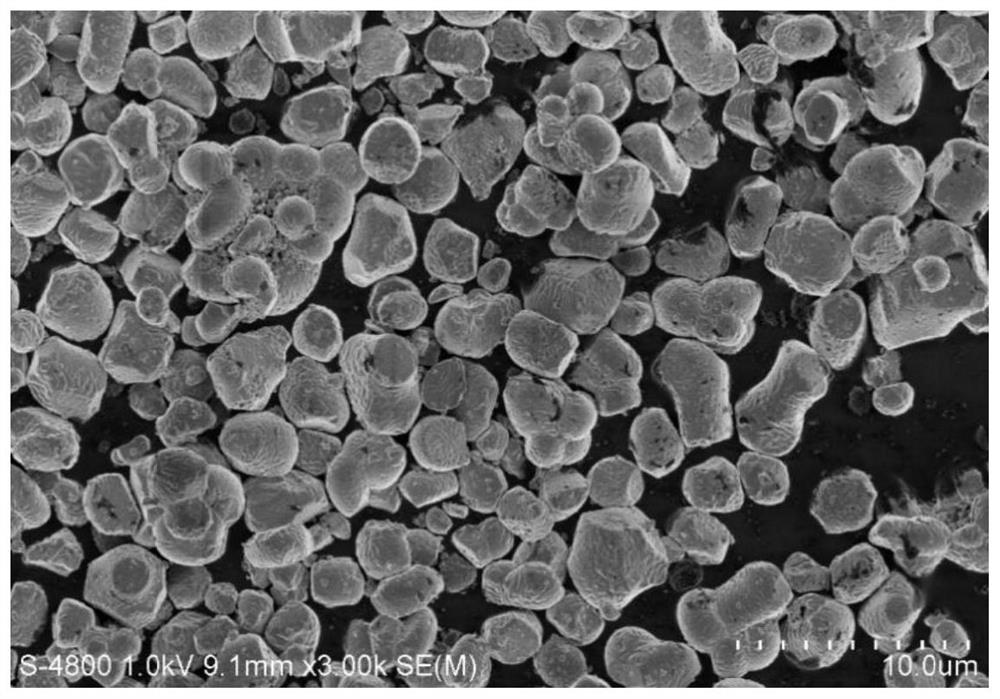

A cathode material and single crystal technology, which is applied in the field of single crystal multi-element cathode material and its preparation, can solve the problems of uneven particle size, poor single wafer wetness, and easy adhesion of particles, and achieves uniform particle size and fewer internal defects. , the effect of good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In the preparation method of the single crystal multi-element cathode material of the present invention, the mixture of the precursor material and the lithium salt is subjected to two high-temperature sintering processes.

[0057] The temperature of the second high-temperature sintering is 20-200°C higher than that of the first high-temperature sintering to ensure that the positive electrode material process product I is obtained through the first high-temperature sintering.

[0058] A second aspect of the present invention provides a method for preparing a single crystal multi-element cathode material, characterized in that the method comprises the following steps:

[0059] S1, the nickel cobalt manganese hydroxide precursor, lithium source, optionally dopant D are mixed to obtain mixture I;

[0060] S2, in oxygen or air atmosphere, carry out the first high temperature sintering to described mixture I, obtain positive electrode material process product I;

[0061] S3,...

Embodiment 1

[0142] I: Preparation of nickel cobalt manganese hydroxide precursors

[0143] (1) Using nickel sulfate, cobalt sulfate, and manganese sulfate as raw materials, according to the molar ratio of Ni:Co:Mn=80:10:10, a uniform nickel, cobalt, and manganese salt mixed solution of 2mol / L is prepared, and 0.2mol / L is prepared. L's La 2 (SO 4 ) 3 solution, 8mol / L NaOH solution was prepared as a precipitating agent, and 25wt% ammonia water was directly used as a complexing agent.

[0144] (2) Under the protection of nitrogen, the above solution was passed into the reactor in a co-current manner, controlled [n(Ni)+n(Co)+n(Mn)]: n(La)=1:0.01, stirred The rotating speed was 200 rpm, the reaction temperature was kept at 55° C., the pH value was 12.3, the co-current time was 23 h, and the mixture was aged for 20 h to obtain a solid-liquid mixed slurry.

[0145] (3) After the solid-liquid mixed slurry is subjected to pressure filtration, washing, and drying at 120° C. for 5 hours, D can b...

Embodiment 2

[0154] I: Preparation of nickel cobalt manganese hydroxide precursors

[0155] (1) Using nickel sulfate, cobalt sulfate, and manganese sulfate as raw materials, according to the molar ratio of Ni:Co:Mn=80:10:10, a uniform nickel, cobalt, and manganese salt mixed solution of 2mol / L is prepared, and 0.2mol / L is prepared. L Ce 2 (SO 4 ) 3 solution, 8mol / L KOH solution was prepared as a precipitating agent, and 25wt% ammonia water was directly used as a complexing agent.

[0156] (2) Under the protection of nitrogen, the above solution was passed into the reaction kettle in a co-current manner, controlled [n(Ni)+n(Co)+n(Mn)]: n(Ce)=1:0.015, stirred The rotating speed was 200 rpm, the reaction temperature was kept at 55° C., the pH value was 12.3, the co-current time was 20 h, and the mixture was aged for 20 h to obtain a solid-liquid mixed slurry.

[0157] (3) After the solid-liquid mixed slurry is washed, filtered by pressure, and dried at 110°C for 5.5 hours, D can be obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com