Vanadium tetrasulfide/vanadium carbide composite material as well as preparation method and application thereof

A composite material, vanadium tetrasulfide technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of low conductivity, poor cycle and rate performance, large volume expansion, etc., to increase the contact specific surface area, improve The effect of electrical conductivity, excellent rate capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

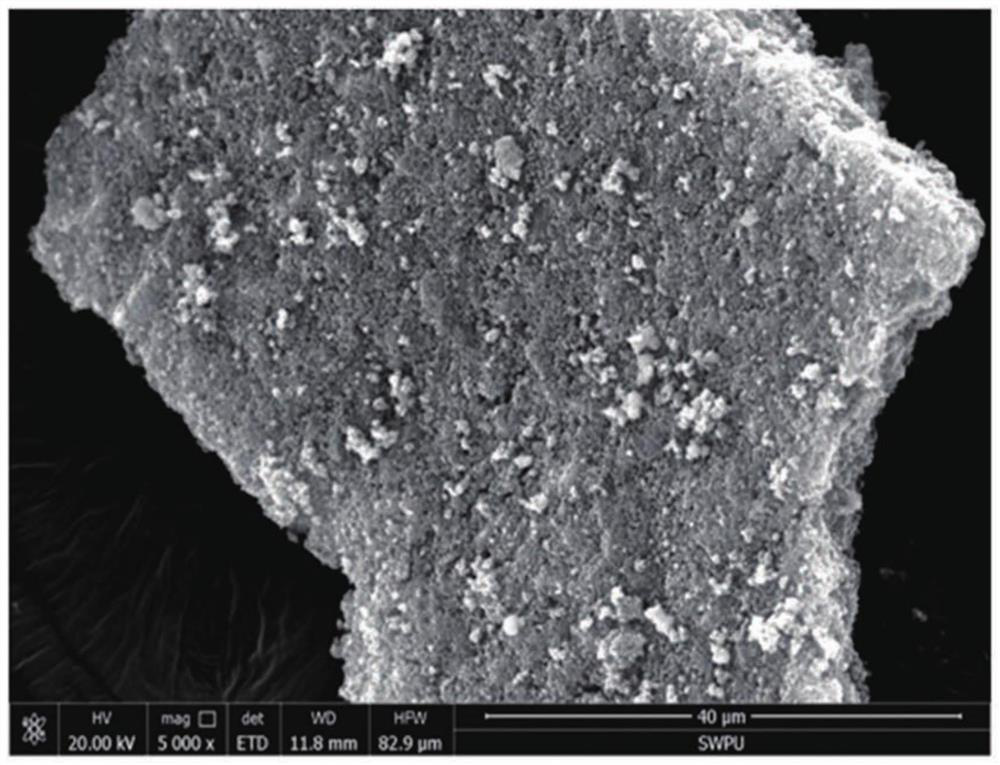

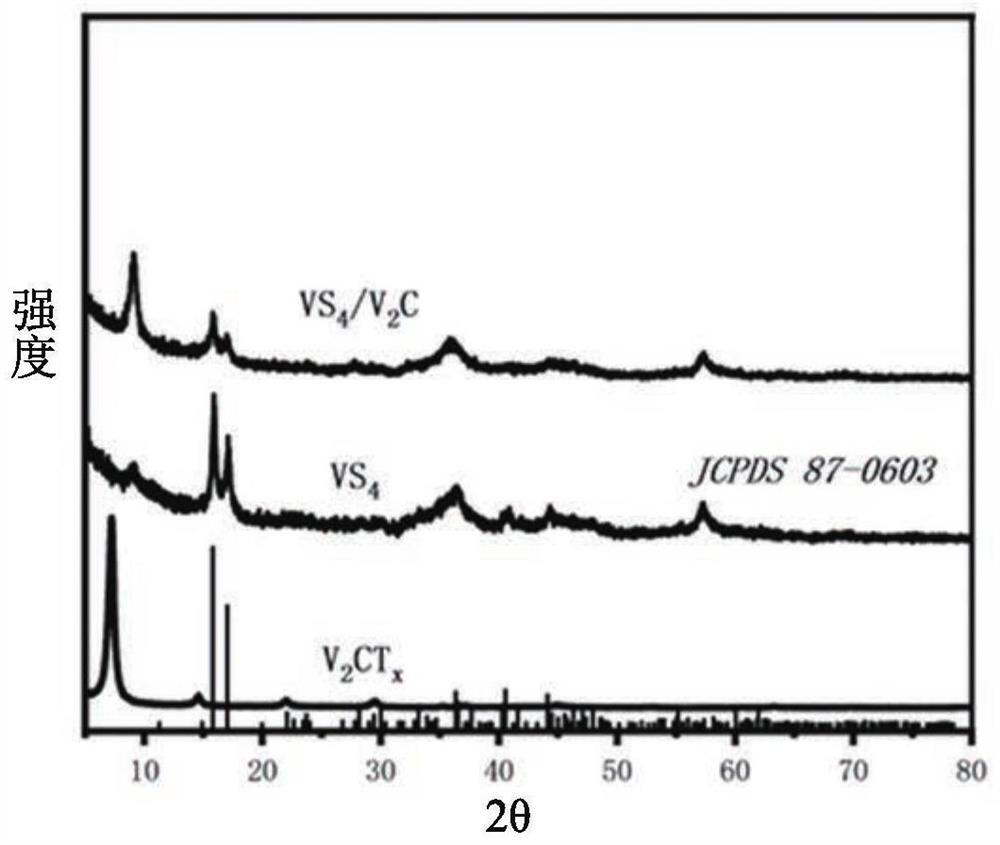

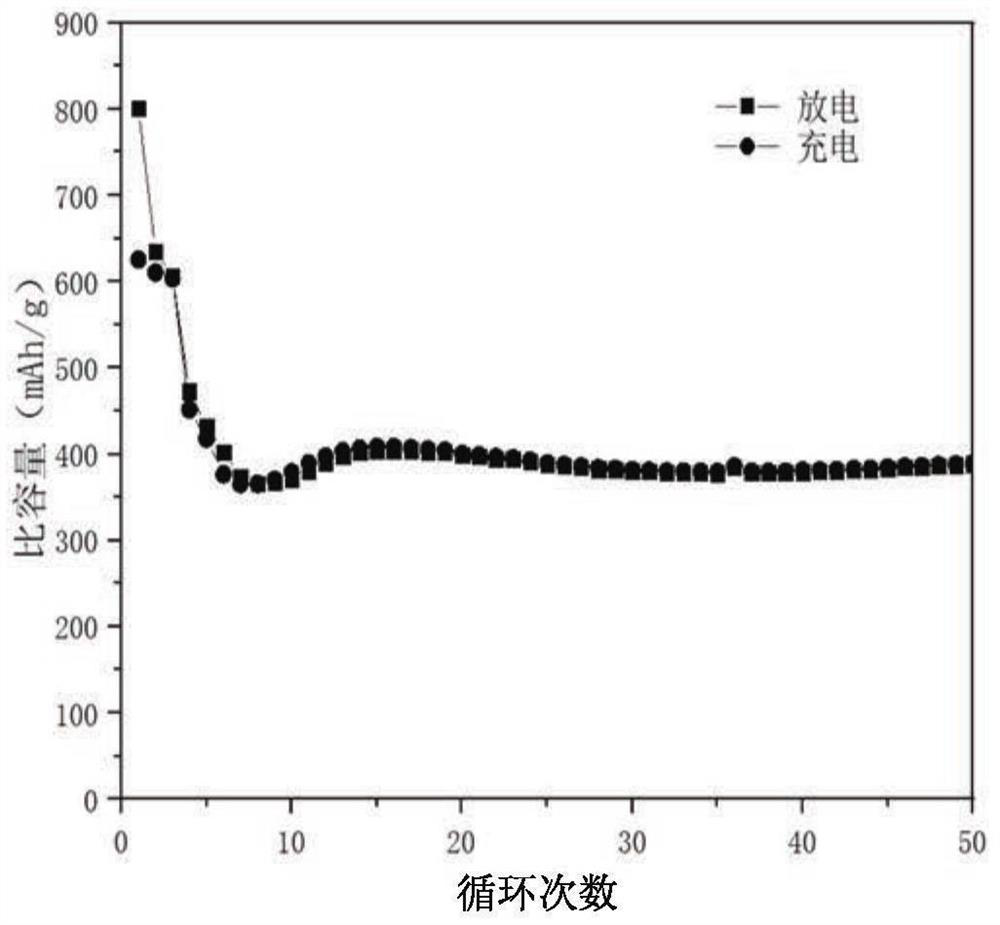

[0059] This example is a kind of preparation of vanadium tetrasulfide / vanadium carbide composite material, and its preparation method comprises the following steps:

[0060] (1) Take 2g vanadium aluminum carbide (V 2 AlC) was added to the polytetrafluoroethylene reaction kettle, and then 40 mL of hydrofluoric acid (HF) with a concentration of 40% was added thereto, the water bath was 35° C., and the reaction was carried out for 24 h. After the reaction, it was centrifuged at 3500 rpm / min, washed with deionized water until neutral, and then transferred to a gas washing bottle, and 20 mL of 5% concentration of tetrabutylammonium hydroxide was added to the gas washing bottle. Atmospheric ventilation intercalation for 24h. V after intercalation 2 CT x Wash to neutrality again by centrifugation at 3500 rpm / min. The washed product was again subjected to ultrasonic stripping with argon or nitrogen for 1 h, and the supernatant was separated by high-speed centrifugation at 5000 rpm...

example 2

[0065] This example is a kind of preparation of vanadium tetrasulfide / vanadium carbide composite material, and its preparation method comprises the following steps:

[0066] (1) Take 2g vanadium aluminum carbide (V 2 AlC) was added to the polytetrafluoroethylene reaction kettle, and then 80 mL of hydrofluoric acid (HF) with a concentration of 40% was added thereto, and the water bath was 40° C., and the reaction was carried out for 24 h. After the reaction, it was centrifuged at 3500 rpm / min, washed with deionized water until neutral, and then transferred to a gas washing bottle, and 20 mL of 5% concentration of tetrabutylammonium hydroxide was added to the gas washing bottle. Atmospheric ventilation intercalation for 24h. V after intercalation 2 CT x Wash again to neutrality by centrifugation at 5000 rpm / min. The washed product was again subjected to ultrasonic stripping with argon or nitrogen for 2 hours, and the supernatant was separated by high-speed centrifugation at ...

example 3

[0070] This example is a kind of preparation of vanadium tetrasulfide / vanadium carbide composite material, and its preparation method comprises the following steps:

[0071] (1) Take 2g vanadium aluminum carbide (V 2 AlC) was added to the polytetrafluoroethylene reaction kettle, and then 40 mL of hydrofluoric acid (HF) with a concentration of 40% was added thereto, the water bath was 40° C., and the reaction was carried out for 24 h. After the reaction, it was centrifuged at 3500 rpm / min, washed with deionized water until neutral, and then transferred to a gas washing bottle, and 20 mL of 7% concentration of tetrabutylammonium hydroxide was added to the gas washing bottle, under argon or nitrogen. Atmospheric ventilation intercalation for 24h. V after intercalation 2 CT x Wash again to neutrality by centrifugation at 5000 rpm / min. The washed product was again subjected to ultrasonic stripping with argon or nitrogen for 2 hours, and the supernatant was separated by high-spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com