Microporous titanium-based iridium tantalum whole-body electrode applied to advanced treatment of chemical tail water as well as preparation method and application of microporous titanium-based iridium tantalum whole-body electrode

A technology of advanced treatment and microporous titanium, which is applied in the fields of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. problem, to achieve the effect of improving catalytic efficiency, improving treatment effect, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Using a microporous titanium-based iridium-tantalum through-body electrode applied to the advanced treatment of chemical tail water of the present invention as an anode, and using stainless steel as a cathode to treat pesticides to produce chemical tail water, the following steps are included:

[0060] Step 1. Prepare a microporous titanium-based iridium-tantalum through-body electrode, and the preparation steps are as follows:

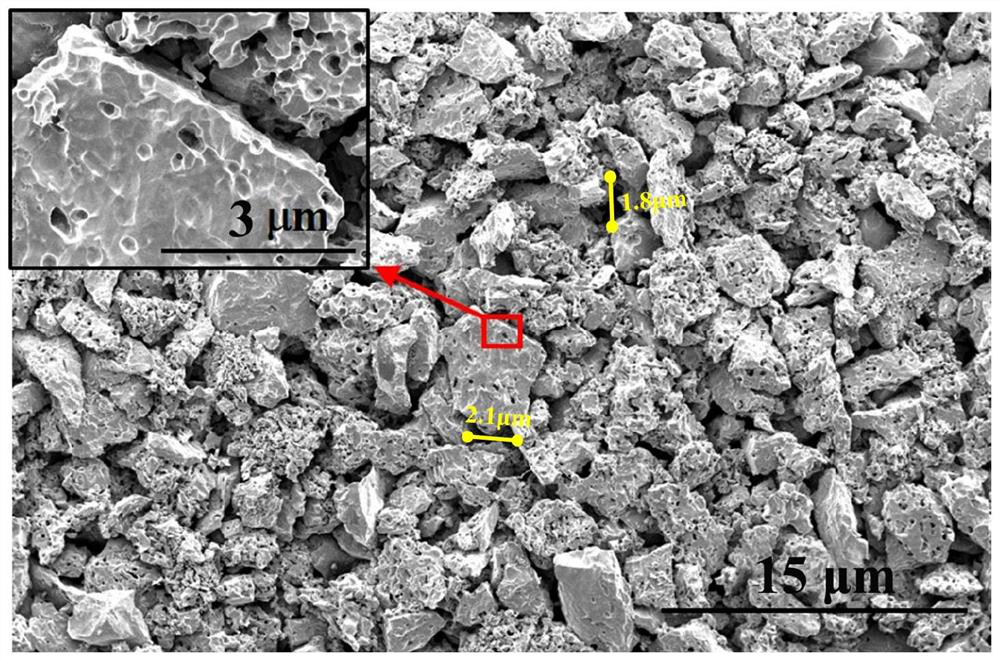

[0061] Step 1: Put titanium powder with a particle size of 5 μm in a 30% oxalic acid solution and heat it to 60°C for 1 hour, rinse with deionized water for 3 times, then boil it in a 10% NaOH solution for 60 minutes, and soak it in deionized water. 12h, dried at 30°C for 1h, passed through a 2500-mesh sieve and put into a ball mill to grind to 5μm to ensure the uniformity of titanium powder particle size;

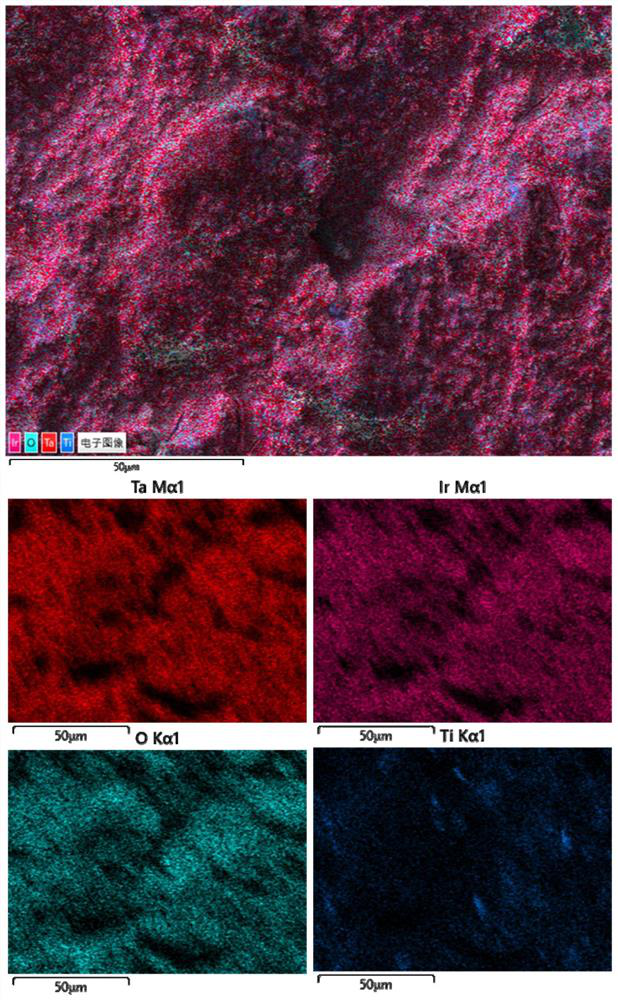

[0062] Step 2: Dissolve 3.4kg of citric acid in 1L of ethylene glycol, and slowly add 140g of chloroiridic acid, 70g of tantalum pentachlo...

Embodiment 2

[0073] Adopting a microporous titanium-based iridium-tantalum through-body electrode applied to the advanced treatment of chemical tail water of the present invention as the anode, and using stainless steel as the cathode to treat the tail water produced by the battery processing enterprise, the following steps are included:

[0074] Step 1. Prepare a microporous titanium-based iridium-tantalum through-body electrode, and the preparation steps are as follows:

[0075] The first step: put titanium powder with a particle size of 10 μm in a 10% oxalic acid solution and heat it to 100 ° C for 1 hour, rinse it with deionized water 3 times, then boil it in a 20% NaOH solution for 30 minutes, and soak it in deionized water. 15h, dried at 40°C for 1h, passed through a 1250-mesh sieve, and then put into a ball mill to grind to 10μm to ensure the uniformity of titanium powder particle size;

[0076] The second step: dissolve 3.4kg of citric acid in 1L of ethylene glycol, and slowly add ...

Embodiment 3

[0083] Using a microporous titanium-based iridium-tantalum through-body electrode applied to the advanced treatment of chemical tail water of the present invention as the anode, and using stainless steel as the cathode to treat the tail water of pharmaceutical production, the following steps are included:

[0084] Step 1. Prepare a microporous titanium-based iridium-tantalum through-body electrode, and the preparation steps are as follows:

[0085] The first step: put titanium powder with a particle size of 7μm in a 10% oxalic acid solution and heat it at 80 ° C for 1 hour, rinse with deionized water 3 times, then boil it in a 15% NaOH solution for 45min, and soak it in deionized water for 12h , dried at 35°C for 1h, passed through a 2000-mesh sieve, and then put into a ball mill and ground to 7μm to ensure the uniformity of titanium powder particle size;

[0086] Step 2: Dissolve 6.8kg of citric acid in 2L of ethylene glycol, and slowly add 260g of chloroiridic acid, 90g of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com