Method for treating heavy metal in organic waste through self-heating type aerobic fermentation

A technology of organic waste and aerobic fermentation, applied in the direction of sludge treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problem of inability to degrade or treat heavy metals in organic waste, affect the quality and treatment effect of fermentation products, and energy conversion efficiency Low-level problems, to achieve the effect of strengthening half-life and microbial activity, promoting aerobic fermentation efficiency, simple process and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

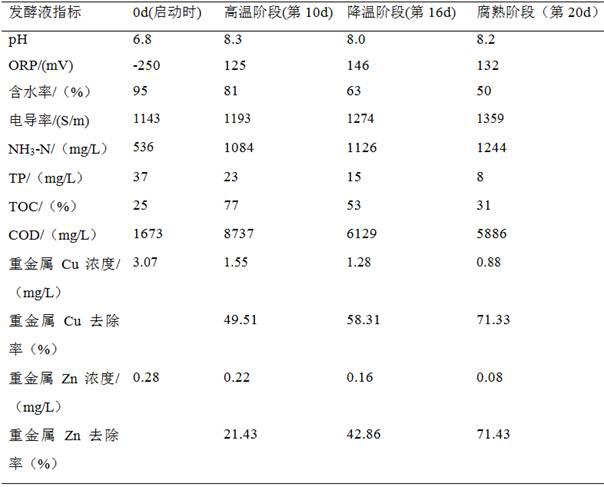

[0023] Embodiment 1: The self-heating aerobic fermentation method treats the residual activated sludge of the sewage treatment plant, and the specific operation is as follows:

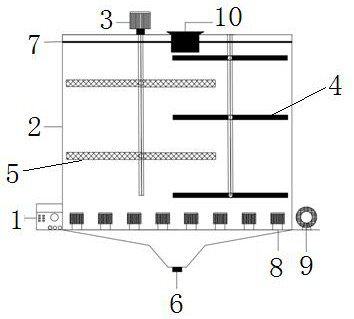

[0024] like figure 1 As shown, the device used in the embodiment includes a reactor 2, the height of the reactor is 2.0m, the length is 2.0m, the width is 2.0m, the anode 4 and the cathode 5 are arranged in the reactor, the distance between the cathode and the anode is 1.0m, and the cathode 5 It is connected with the motor 3 set at the top of the reactor, the feed port 10 is set at the top of the reactor, the discharge port 6 is set at the bottom of the reactor, and 15 microporous aerators 8 (each microporous aerator is aerated) The area is 0.4m 2 ) at the bottom of the reactor and communicated with the air pump 9, the overflow weir 7 is arranged on the top of the reactor, the anode and the cathode are respectively connected with the DC power supply 1; the cathode is an electrode with a plurality of g...

Embodiment 2

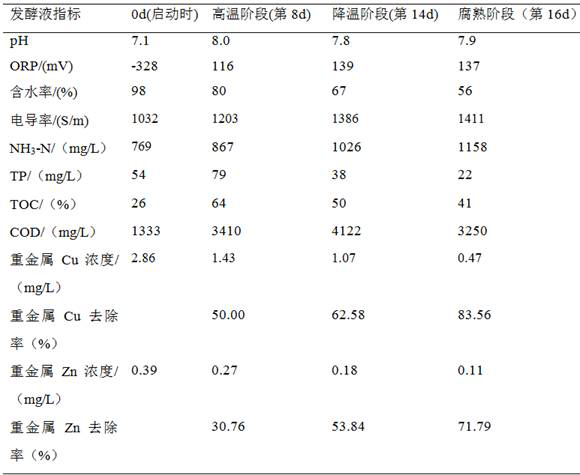

[0033] Embodiment 2: self-heating type aerobic fermentation method handles cattle and sheep manure, and concrete operation is as follows:

[0034] The device used in this example is the same as that in Example 1, except that the graphite mesh pole pieces are provided with 2 layers, with 5 pieces in each layer; the anode is an electrode with a plurality of nickel oxide pole pieces on the shaft, and the nickel oxide pole piece pole piece Set 2 layers, 5 pieces per layer; set 20 microporous aerators, and the aeration area of each microporous aerator is 0.2m 2 ;

[0035] The nickel oxide pole piece is immersed in a hydrochloric acid solution with a concentration of 25g / L, and then taken out after ultrasonication for 12 minutes, and then placed in a mixture of ethanol and acetone with a volume ratio of 1:1 to continue ultrasonication for 12 minutes, and vacuum dried at 90 °C for 19 hours. After placing it in a cobalt chloride solution with a concentration of 125 g / L, the current...

Embodiment 3

[0043] Embodiment 3: the self-heating aerobic fermentation method handles the kitchen waste, and the concrete operation is as follows:

[0044] The device used in this example is the same as that in Example 1, except that the graphite mesh pole pieces are provided with 2 layers, with 6 pieces in each layer; the anode is an electrode with a plurality of nickel oxide pole pieces on the shaft, and the nickel oxide pole piece pole piece Set 2 layers, 6 pieces per layer; set 10 microporous aerators, and the aeration area of each microporous aerator is 0.5m 2 ;

[0045] The nickel oxide pole piece is immersed in a hydrochloric acid solution with a concentration of 30g / L, and then taken out after ultrasonication for 15 minutes, and then placed in a mixture of ethanol and acetone with a volume ratio of 1:1 for more than 8 minutes, and vacuum dried at 100 °C for 18 hours. Then, it was placed in a cobalt chloride solution with a concentration of 100 g / L, and the current density of 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com