Method for producing 1, 4-butanediamine by fermenting xylose and xylose-containing hydrolysate

A technology of agmatase and xylose isomerase, applied in the field of genetic engineering, can solve the problems of low final yield and the like, and achieve the effect of expanding carbon sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

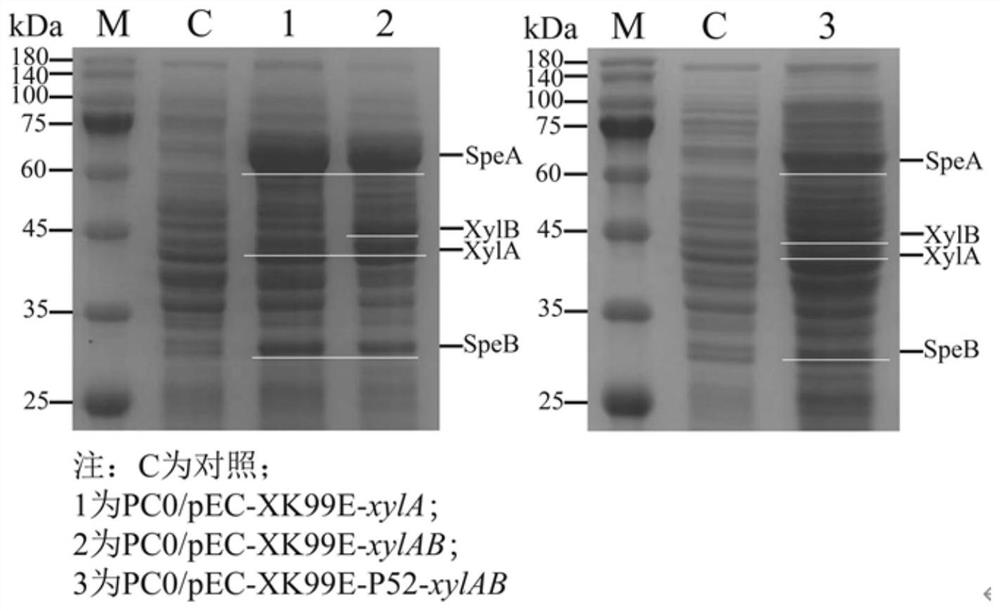

[0044] Example 1: Construction of recombinant bacteria PC0 / pEC-XK99E-xylA, PC0 / pEC-XK99E-xylAB and PC0 / pEC-XK99E-P52-xylAB

[0045] (1) Primer design

[0046] According to the gene sequence of xylA (the nucleotide sequence encoding the xylose isomerase is shown in SEQ ID NO 6) and the gene sequence of xylB (the nucleotide sequence encoding the xylulokinase) in the whole genome nucleic acid sequence of Escherichia coli K-12 in NCBI The nucleotide sequence is shown in SEQ ID NO 7), the PCR primer F of the design plasmid pEC-XK99E-xylA 1 and R 1 , PCR primer F of pEC-XK99E-xylAB 2 and R 2 , PCR primer F of pEC-XK99E-P52-xylAB 3 and R 3 and F 4 and R 4 .

[0047] F 1 : 5'-caggaaacagaccatggaattcaaaggaggacaaccatgcaagcctattttgaccagc-3';

[0048] R 1 : 5'-gcaggtcgactctagaggatccttatttgtcgaacagataatggtttaccag-3';

[0049] F 2 : 5'-caggaaacagaccatggaattcaaaggaggacaaccatgcaagcctattttgaccagc-3';

[0050] R 2 :5'-gcaggtcgactctagaggatccttacgccattaatggcagaagttgc-3';

[0051] F...

Embodiment 2

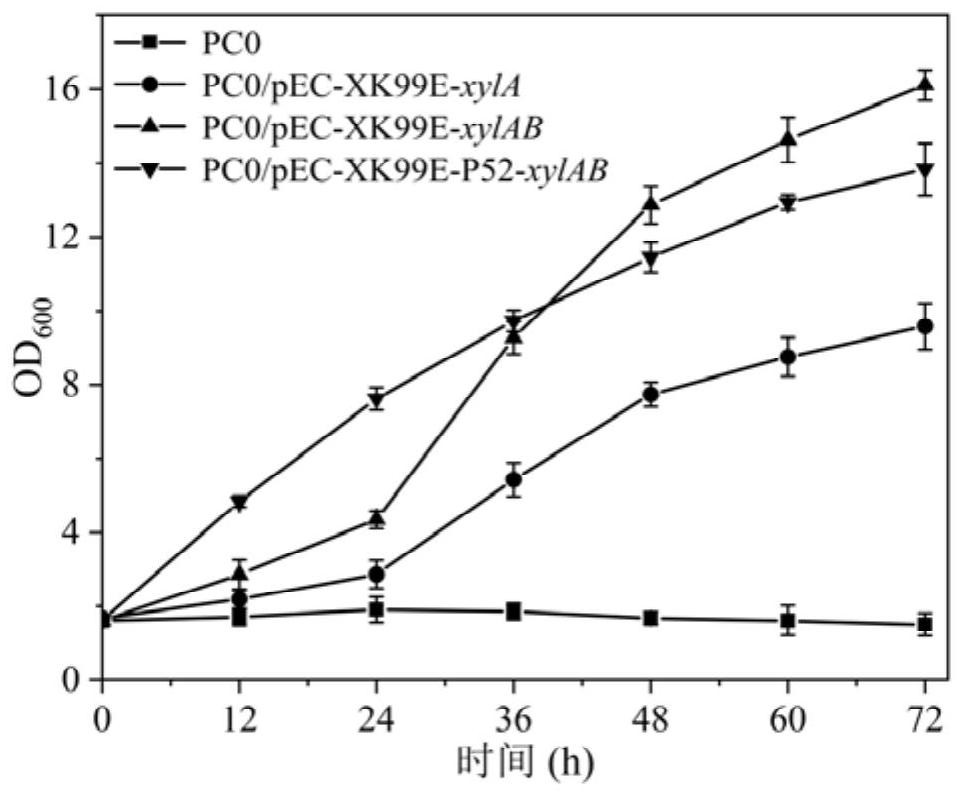

[0066] Example 2: Growth assay of recombinant bacteria PC0 / pEC-XK99E-xylA, PC0 / pEC-XK99E-xylAB, PC0 / pEC-XK99E-P52-xylAB in the medium with only xylose carbon source

[0067] (1) Preparation of culture medium:

[0068] Seed medium (g L -1 ): glucose 50, (NH 4 ) 2 SO 4 20, Yeast Powder 20, KH 2 PO 4 1.5, MgS0 4 ·7H 2 O1.0, MnS0 4 ·H 2 O 0.3, CaCO 3 1.0;

[0069] Fermentation medium (g L -1 ): Xylose 100, (NH 4 ) 2 SO 4 40, Yeast Powder 10, KH 2 PO 4 1.5, KCl 1.0, MgS0 4 ·7H 2 O 0.5, MnS0 4 ·H 2 O 0.02, FeS0 4 ·7H 2 O 0.02, CaCO 3 20.

[0070] (2) The recombinant bacteria PC0 / pEC-XK99E-xylA, PC0 / pEC-XK99E-xylAB, PC0 / pEC-XK99E-P52-xylAB constructed in Example 1 and the starting strain PC0 were respectively mixed with a concentration of 10 μg·mL -1 Chloramphenicol or 10μg·mL -1 Chloramphenicol and 50 μg·mL -1 After the kanamycin-resistant BHI solid medium is streaked and activated, a single colony is picked and inoculated into the seed medium prepar...

Embodiment 3

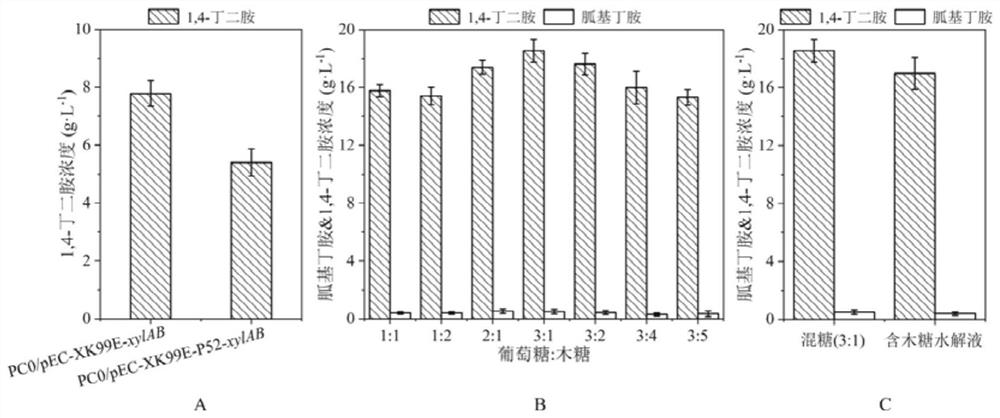

[0073] Example 3: Shake flask fermentation production of 1,4-butanediamine by recombinant bacteria PC0 / pEC-XK99E-xylAB and PC0 / pEC-XK99E-P52-xylAB

[0074] (1) Preparation of culture medium:

[0075] Seed medium (g L -1 ): glucose 50, (NH 4 ) 2 SO 4 20, Yeast Powder 20, KH 2 PO 4 1.5, MgS0 4 ·7H 2 O1.0, MnS0 4 ·H 2 O 0.3, CaCO 3 1.0;

[0076] Fermentation medium (g L -1 ): carbon source 150, (NH 4 ) 2 SO 4 40, Yeast Powder 10, KH 2 PO 4 1.5, KCl 1.0, MgS0 4 ·7H 2 O 0.5, MnS0 4 ·H 2 O 0.02, FeS0 4 ·7H 2 O 0.02, CaCO 3 20.

[0077] Wherein: the carbon source is prepared by mixing xylose and glucose in a mass ratio of 1:1, 1:2, 2:1, 3:1, 3:2, 3:4, and 3:5, respectively. The concentration is 150g·L -1 mixed sugar as a carbon source.

[0078] (2) The recombinant bacteria PC0 / pEC-XK99E-xylAB and PC0 / pEC-XK99E-P52-xylAB constructed in Example 1 were respectively mixed with a concentration of 10 μg·mL -1 Chloramphenicol and 50 μg·mL -1 After the kana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com