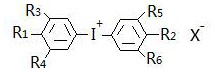

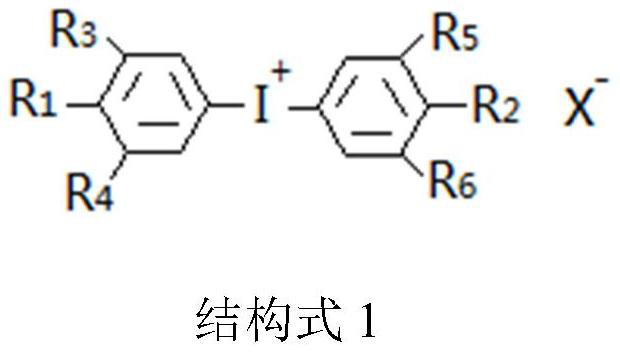

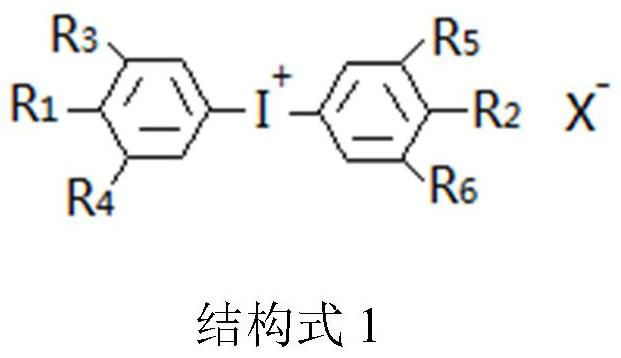

Iodonium salt initiator, treatment-free thermo-sensitive plate precursor containing iodonium salt initiator, treatment-free thermo-sensitive plate and application of iodonium salt initiator

A technology of initiator and iodonium salt, applied in the field of lithography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example

[0109] Synthesis of iodonium salt D13:

[0110] Add 23g sodium borate tetrahydrate, 40g acetic acid, 60g acetic anhydride to a 500ml four-necked flask with temperature-controlled heating, mechanical stirring, condensation reflux and nitrogen protection device, stir at 30 ° C for 1.5 hours, then add 58.2g 3,5 -Dimethyl-4-tert-butyl-p-iodobenzene, stirred at 40°C for 1.5 hours, then cooled to 0°C, and then added 43.4g of N-(ethyl acrylate)-2,6-dimethyl-benzoic acid , the temperature is controlled below 5 ℃, the mixture of 30 ml of concentrated sulfuric acid and 30 ml of acetic acid is added dropwise, the temperature is raised to 15 ℃ and stirred for 24 hours, the reaction solution is poured into ice water and stirred for 0.5 hours, extracted 3 times with petroleum ether, 1000ml of ammonium chloride aqueous solution with a mass fraction of 20% was slowly added dropwise, the solid was precipitated, filtered, washed with deionized water, and dried in vacuo. Then the obtained solid ...

Embodiment 1

[0131]Preparation of plate base: A1050 rolled aluminum plate with a purity of 99.5% and a thickness of 0.3 mm was etched in a sodium hydroxide aqueous solution with a mass fraction of 5% at 70 ° C for 20 seconds, rinsed with running water, and immediately used with a mass fraction of 1%. nitric acid aqueous solution. Then in 1% hydrochloric acid aqueous solution, sine wave alternating current at 40°C at 50A / dm 2 The current density was electrolytic roughening for 16 seconds, followed by neutralization with 5% sodium hydroxide aqueous solution by mass fraction for 10 seconds at 40 °C, and washing with water. Finally, at 30 ° C, with a mass fraction of 20% sulfuric acid aqueous solution, at 15A / dm 2 current density, anodized for 20 seconds, and washed with water. At 80°C, the pores were sealed with a 5% sodium silicate aqueous solution for 18 seconds, washed with water, and dried. The plate base thus obtained had an average centerline thickness of 0.5 μm and an oxide film weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com