Volatile composite cutting fluid for aluminum foil and copper foil and preparation method of volatile composite cutting fluid

A composite cutting fluid technology, applied in lubricating compositions, petroleum industry, etc., can solve the problem of synergistic lubrication between Guerbet alcohols and olefins that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the above-mentioned aluminum foil and copper foil no-cleaning oily cutting fluid comprises the following steps:

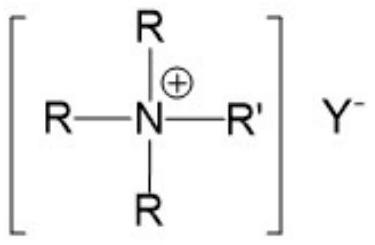

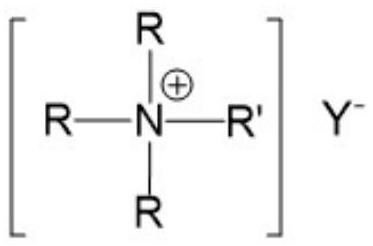

[0037] (1) After mixing trialkylamine and halogenated alkane, add it to solvent acetone or acetonitrile, the molar ratio of reactants is trialkylamine: halogenated alkane)=1:(1.25~1.75), every trialkylamine and solvent The ratio of 0.1mol:100mL. The above solution is reacted under a protective atmosphere of 70-90°C for 24-48h, washed and dried to obtain polyalkylammonium halide; the trialkylamines are triethylamine, tripropylamine, tributylamine, and triamylamine , a kind of trihexylamine; halogenated alkane is bromoethane, bromopropane, bromobutane, bromopentane, bromohexane, iodoethane, iodopropane, iodobutane, iodopentane, iodohexane a kind of;

[0038](2) Add polyalkylammonium halide to deionized water, stir well, then add metal salt solution, the molar ratio of polyalkylammonium halide to metal salt solution is 1:(1.25~1.75),...

Embodiment 1

[0042] Follow the steps below to first synthesize polyalkyl ionic liquids:

[0043] (1) 0.1 mol of tripropylamine and 0.10 mol of bromopropane were mixed and added to 100 mL of acetone, reacted under a nitrogen atmosphere at 70° C. for 24 h, washed and dried to obtain tetrapropylammonium halide;

[0044] (2) Add the tetrapropylammonium halide obtained in step (1) into 100 mL of deionized water, stir evenly, then add 0.125 mol of metal salt solution, stir for 10 h, then add dichloromethane to extract the organic phase, and collect the organic phase by liquid separation , and then repeatedly washed with deionized water for many times, and finally the dichloromethane in the solution was removed by rotary evaporation, and the polyalkyl ionic liquid was obtained by drying;

[0045] (3) Weigh the components of the following proportions respectively:

[0046] Table 1 embodiment 1 material ratio (mass percent)

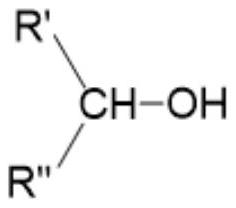

[0047] Saturated alkanes 10% Decene 10% 2-Ethyl-1-...

Embodiment 2

[0050] Follow the steps below to first synthesize polyalkyl ionic liquids:

[0051] (1) 0.1 mol of trihexylamine and 0.125 mol of iodopentane were mixed and added to 100 mL of acetone, reacted under a protective atmosphere of 70°C for 36 h, washed and dried to obtain trihexyl-pentyl-ammonium halide;

[0052] Trihexylamine can be replaced with triethylamine or tributylamine. Iodopentane can be a kind of in other halogenated alkanes such as bromoethane, bromobutane, bromopentane, iodoethane, iodopropane, iodobutane and iodohexane;

[0053] (2) Add the trihexyl-pentyl-ammonium halide obtained in step (1) into 100 mL of deionized water, and stir

[0054] uniformly, then add 0.10moL metal salt solution, stir for 8h, then add dichloromethane to extract the organic phase, collect the organic phase through liquid separation, and then repeatedly wash with deionized water for several times, and finally remove the dichloride in the solution by rotary evaporation Methane, after drying t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com