Preparation method of composite microcapsule liquid beverage containing calendula oil resin

A compound technology of calendula oil and resin, which is applied in the field of food processing, can solve problems such as difficulty in increasing consumer satisfaction, imperfect preparation process, unsuitable for diabetic patients, etc., to expand the consumer market, and to achieve uniform and stable liquid state , Improve the effect of fusion and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

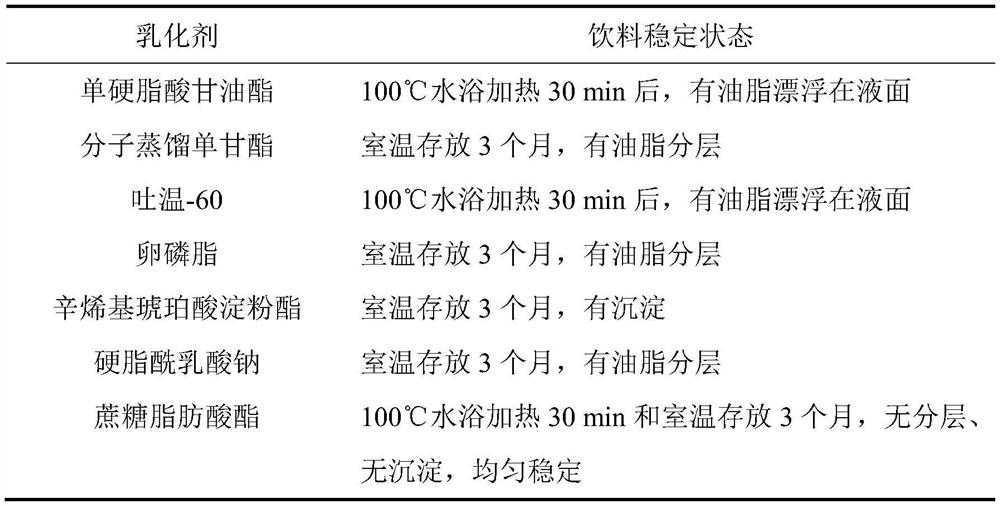

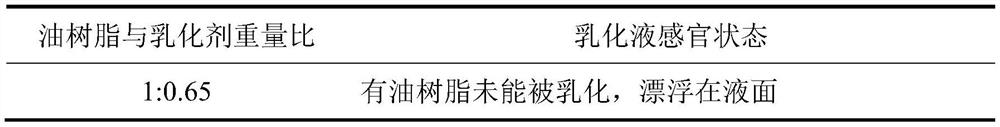

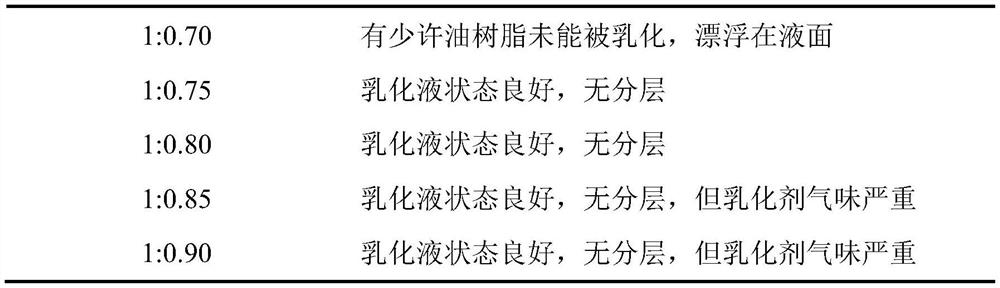

Method used

Image

Examples

Embodiment 1

[0021] Crush the clean marigold flowers with a moisture content of 15%, pass through a 40-mesh sieve, and pass through supercritical CO 2 The fluid extraction equipment extracts calendula oleoresin, and the extraction conditions are: extraction temperature 60 ℃, pressure 30 MPa, CO 2 The flow rate is 15L / h, the temperature of separation kettle I is 40°C, the pressure is 6MPa, and the temperature of separation kettle II is 20°C, and the obtained oleoresin is in the form of a brown-red paste with the unique flavor of calendula.

[0022] Dissolve 0.64 g of sucrose fatty acid ester (emulsifier) in 100 mL of water, add 0.8 g of calendula oleoresin, stir magnetically for 20 min to obtain an emulsion, add water according to the volume ratio of emulsion to water 1:4, stir well, and then Add β-cyclodextrin and sodium alginate in turn (add 8g of β-cyclodextrin first, stir evenly, let stand for 5 minutes, then add 4 g of sodium alginate, slowly stir for 5 minutes, let stand for 15 minu...

Embodiment 2

[0034] Crush the clean marigold flowers with a moisture content of 15%, pass through a 40-mesh sieve, and pass through supercritical CO 2 The fluid extraction equipment extracts calendula oleoresin, and the extraction conditions are: extraction temperature 60 ℃, pressure 30 MPa, CO 2 The flow rate is 15L / h, the temperature of separation kettle I is 40°C, the pressure is 6MPa, and the temperature of separation kettle II is 20°C. The obtained oleoresin is brown-red paste with the unique flavor of calendula.

[0035] Dissolve 0.6kg of sucrose fatty acid ester (emulsifier) in 100L of water, add 0.8kg of calendula oleoresin, stir magnetically for 30min to obtain an emulsion, add water according to the volume ratio of emulsion to water 1:4, stir well, then Add β-cyclodextrin and sodium alginate in sequence (add 8g of β-cyclodextrin first, stir evenly, let stand for 5 minutes, then add 4 g of sodium alginate, slowly stir for 5 minutes, let stand for 15 minutes), stir magnetically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com