Cobalt-free high-nickel ternary gradient lithium ion battery positive electrode material and preparation method thereof

A lithium ion battery and cathode material technology, which is applied in the field of cobalt-free high nickel ternary gradient lithium ion battery cathode material and its preparation, can solve the problem that the electrochemical performance of the material cannot meet expectations, limit the wide application of lithium ion batteries, and cannot be completely avoided. Cobalt use and other issues, to achieve the effect of inhibiting Li/Ni mixing, improving electrochemical performance, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a method for preparing a positive electrode material for a cobalt-free and high-nickel ternary gradient lithium ion battery, comprising the following steps:

[0044] (1) nickel salt and manganese salt are dissolved in water to obtain high nickel mixed solution A;

[0045] Dissolve nickel salt, manganese salt and M salt in water to obtain mixed solution B of medium nickel;

[0046] Dissolve nickel salt, manganese salt and M salt in water to obtain low nickel mixed solution C;

[0047] (2) mixing mixed solution A, sodium hydroxide solution and ammonia water, and carrying out the first coprecipitation reaction under protective gas; then adding mixed solution B, carrying out the second coprecipitation reaction under protective gas; then adding mixed solution C, carry out the third co-precipitation reaction under protective gas;

[0048] (3) ageing, filtering and drying the reaction product of step (2) to obtain a bulk material precursor...

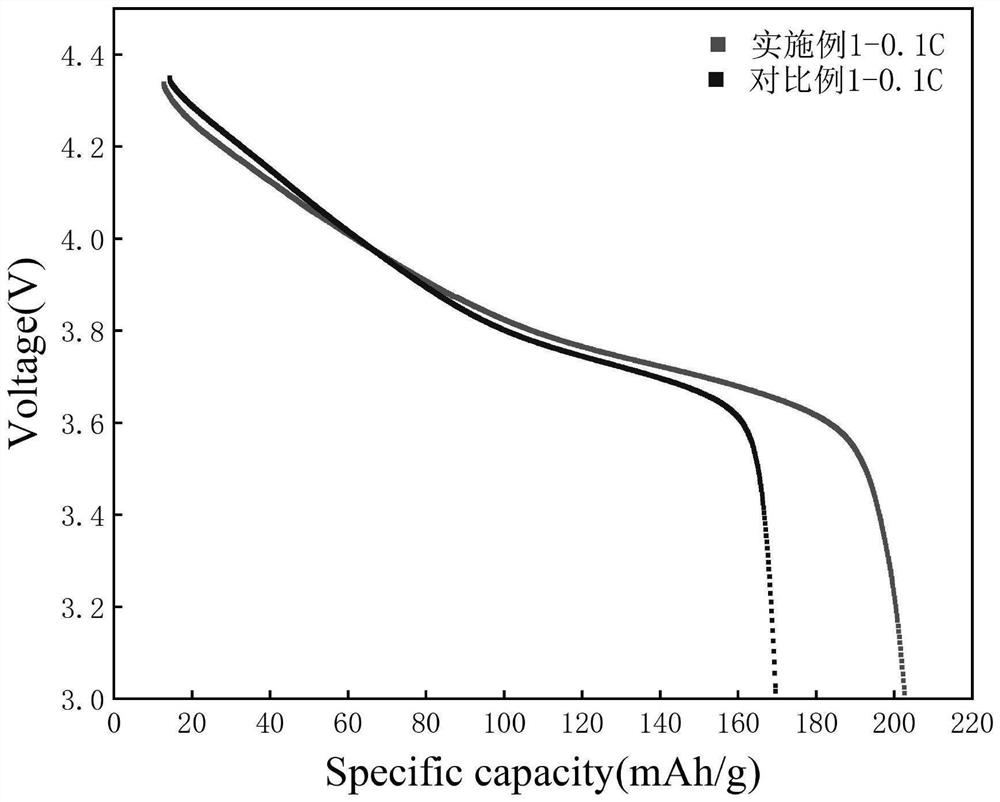

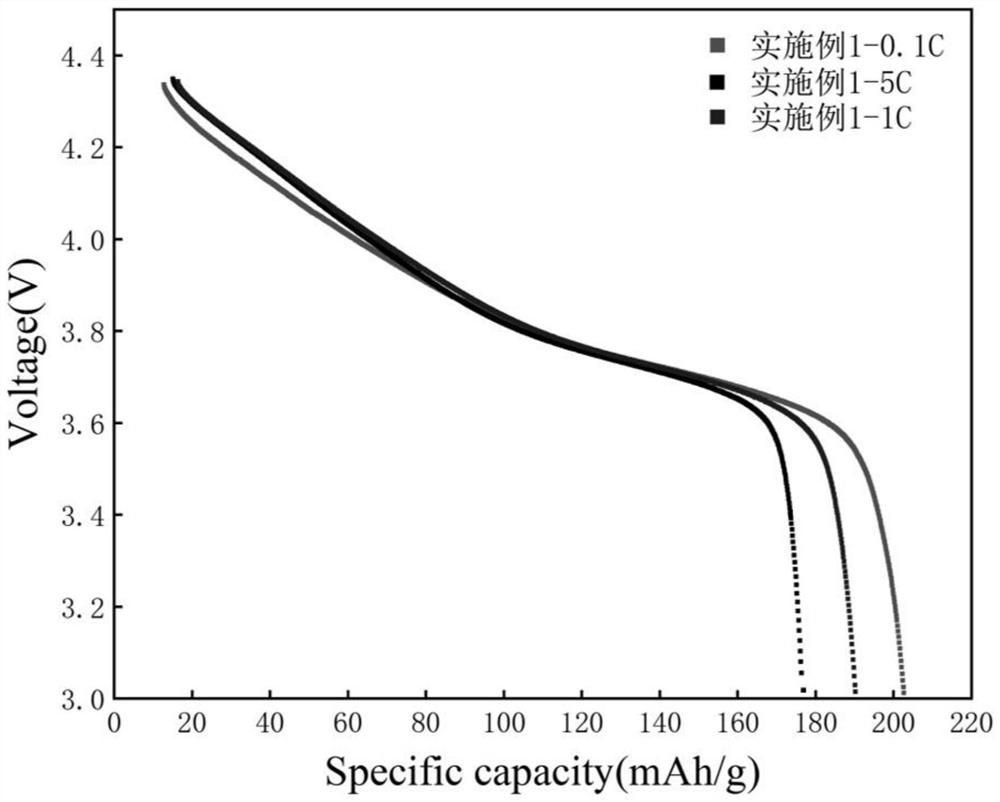

Embodiment 1

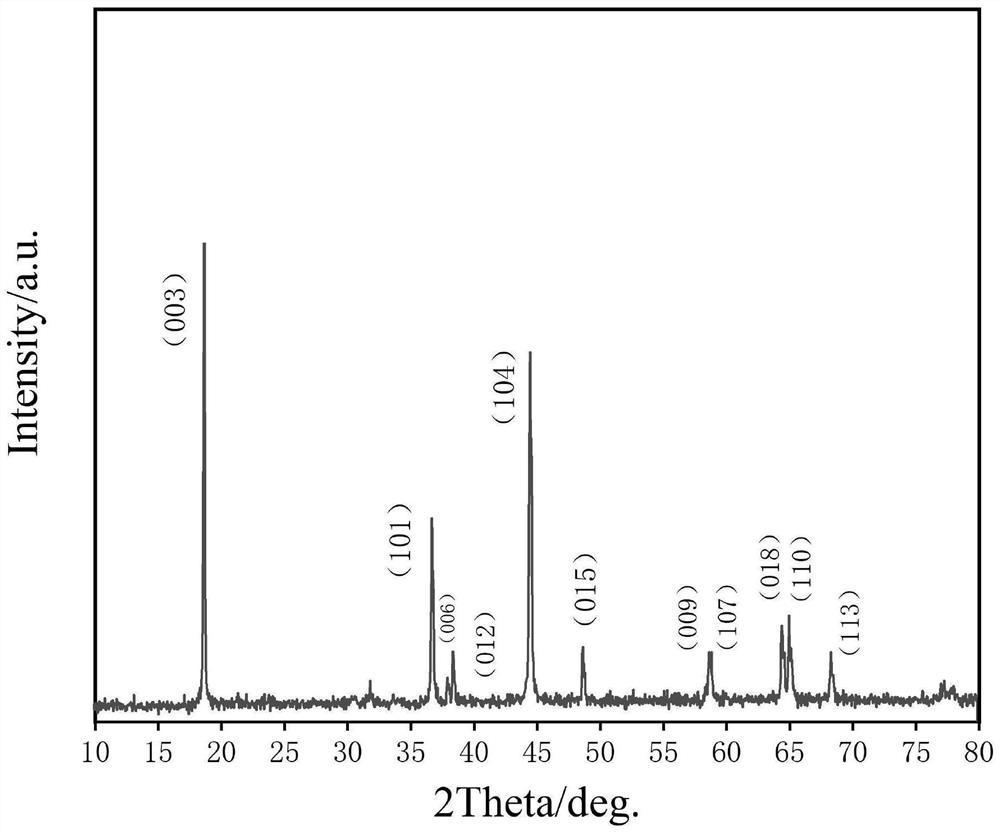

[0061] This embodiment provides a Li 2 TiO 3 and Li 2 ZrO 3 Coated LiNi 0.83 Mg 0.08 Mn 0.09 O 2 A positive electrode material for a ternary gradient lithium ion battery, and the preparation method thereof includes the following steps:

[0062] (1) be mixed solution A of the high nickel of 4mol / L with nickel nitrate, manganese nitrate by molar ratio of 9:1;

[0063] The nickel nitrate, manganese nitrate, and magnesium nitrate are prepared in a molar ratio of 5:3:2 into a mixed solution B of medium nickel with a concentration of 2mol / L;

[0064] The nickel nitrate, manganese nitrate, and magnesium nitrate are prepared in a molar ratio of 1:1:1 into a low-nickel mixed solution C with a concentration of 1 mol / L;

[0065] (2) mixed solution A, the sodium hydroxide solution of 5mol / L and the ammoniacal liquor of 4mol / L were pumped into the nitrogen-filled reactor at the rate of 0.1L / h, 0.1L / h, 0.1L / h respectively, and carried out The first co-precipitation reaction was car...

Embodiment 2

[0070] This embodiment provides a Li 2 TiO 3 and Li 2 ZrO 3 Coated LiNi 0.79 Zr 0.10 Mn 0.11 O 2 A positive electrode material for a ternary gradient lithium ion battery, and the preparation method thereof includes the following steps:

[0071] (1) be mixed solution A of the high nickel of 4.5mol / L with nickel nitrate, manganese nitrate by molar ratio of 8:2;

[0072] The nickel nitrate, manganese nitrate, and zirconium nitrate pentahydrate are prepared in a molar ratio of 6:2:2 into a mixed solution B of medium nickel with a concentration of 2mol / L;

[0073] The nickel nitrate, manganese nitrate, and zirconium nitrate pentahydrate are prepared in a molar ratio of 1:1:1 into a low-nickel mixed solution C with a concentration of 1.2 mol / L;

[0074] (2) mixed solution A, the sodium hydroxide solution of 3mol / L and the ammoniacal liquor of 3mol / L were pumped into the nitrogen-filled reactor at the rate of 0.2L / h, 0.3L / h, 0.1L / h respectively, and carried out The first co-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com