Porous titanium silicalite molecular sieve, modified titanium silicalite molecular sieve, modified molecular sieve and preparation method and application thereof

A titanium-silicon molecular sieve and silicon molecular sieve technology, applied in the fields of modified titanium-silicon molecular sieve, modified molecular sieve and its preparation, and porous titanium-silicon molecular sieve, can solve the problems of unclear specific role of amorphous titanium species, and achieve improved catalytic performance, The effect of high specific surface area and high hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

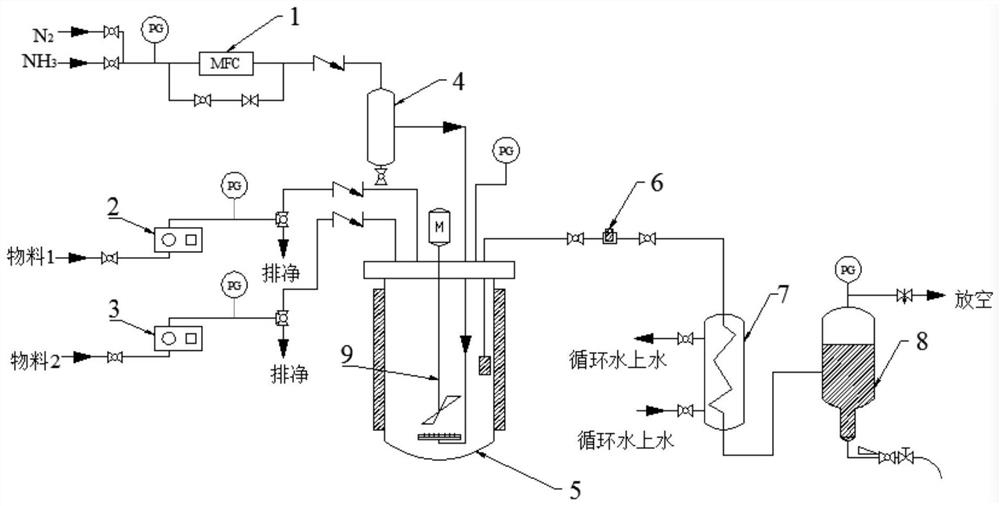

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1: The preparation method of Ti-DMS titanium-silicon molecular sieve C is as follows:

[0067] (1) Preparation of the first mixed solution: Weigh 0.64g of cetyltrimethylammonium bromide, 0.4g of urea and 50ml of high-purity water, and stir for 30 minutes until the cetyltrimethylammonium bromide is completely dissolved, forming the first a mixture.

[0068] (2) Preparation of the second mixed solution: Measure 1.5 ml of n-pentanol, 3.6 ml of ethyl orthosilicate, 0.2 ml of tetrabutyl titanate and 50 ml of cyclohexane to form a second mixed solution after they are fully mixed.

[0069] (3) The second mixed solution was quickly poured into the first mixed solution, kept at 25°C, and stirred at 700 rpm for 30 minutes to form a stable microemulsion system.

[0070] (4) The microemulsion obtained in step (3) was transferred to an autoclave with a Teflon substrate, and then the autoclave was placed in an oven at 120° C. and allowed to stand for 12 hours. After the ...

Embodiment 2

[0071] Example 2: Ti-DMS alkali-modified C1

[0072]The Ti-DMS titanium-silicon molecular sieve C prepared in Example 1 was modified with a weak alkaline mixed solution. Pipette 3.5ml of organic base (N,N-dimethyldecylamine) into 100ml of high-purity water and stir for 1 hour, then weigh 3g of Ti-DMS titanium-silicon molecular sieve C and disperse it in the above solution and continue to stir for 80min until it is fully dispersed After homogenization, the above-mentioned emulsion was transferred to an autoclave, and heated at a high temperature for 48 hours under the reaction conditions of 120° C. in a static state. After the reaction was completed, the synthesized product was centrifuged at 2000 r / min for 20 min, washed with water and anhydrous ethanol for 3 times, and vacuum-dried in a vacuum drying box at 60 ° C for 12 hours to obtain the modified titanium-silicon molecular sieve C1. The diameter is 1.5μm, and the specific surface area is 680m 2 / g, the ratio of titanium ...

Embodiment 3

[0073] Example 3: Ti-DMS hydrophilic and hydrophobic modified C2

[0074] The Ti-DMS titanium-silicon molecular sieve C prepared in Example 1 was modified with a silane coupling agent. Put 1.5g of Ti-DMS titanium-silicon molecular sieve C and 1ml of silane coupling agent (trimethylchlorosilane) in 120ml of dry toluene, and under the protection of nitrogen with a purity of 99.9%, stir and reflux in an oil bath at 100 ° C for 12 hours . After the reaction is finished, it is cooled to room temperature, and centrifugal sedimentation is carried out (rotating speed is 2000r / min, time is 20min) to obtain modified molecular sieve C2, its particle size is 1.7 microns, and the specific surface area is 110 m 2 / g, the ratio of titanium to silicon is 3.6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com