Catalytic yellow phosphorus tail gas oxidizing and purifying method in fixed bed

A technology for catalytic oxidation and yellow phosphorus tail gas, applied in chemical instruments and methods, phosphorus compounds, separation methods, etc., can solve the problems of inability to meet the raw material gas requirements of one-carbon chemical industry, low phosphorus removal efficiency, incomplete phosphorus removal, etc. , to achieve the effect of cheap catalyst, simple process flow and increased oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

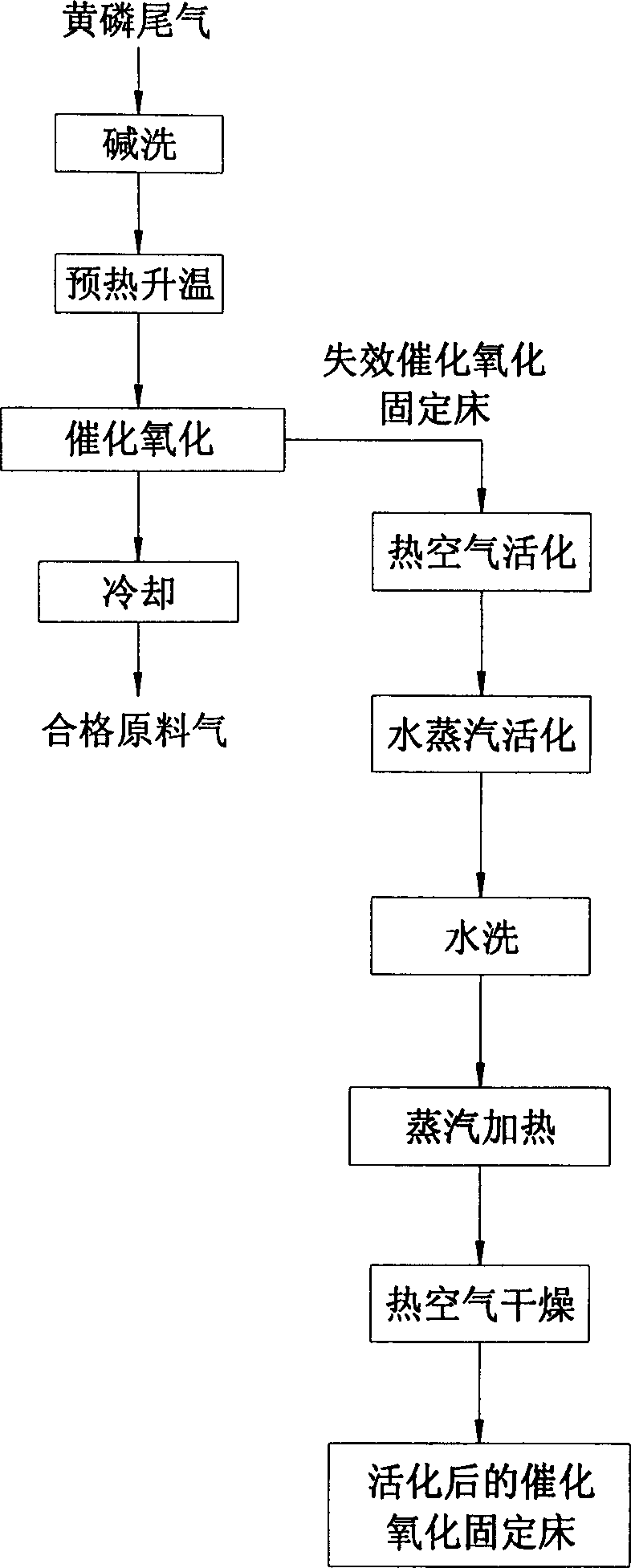

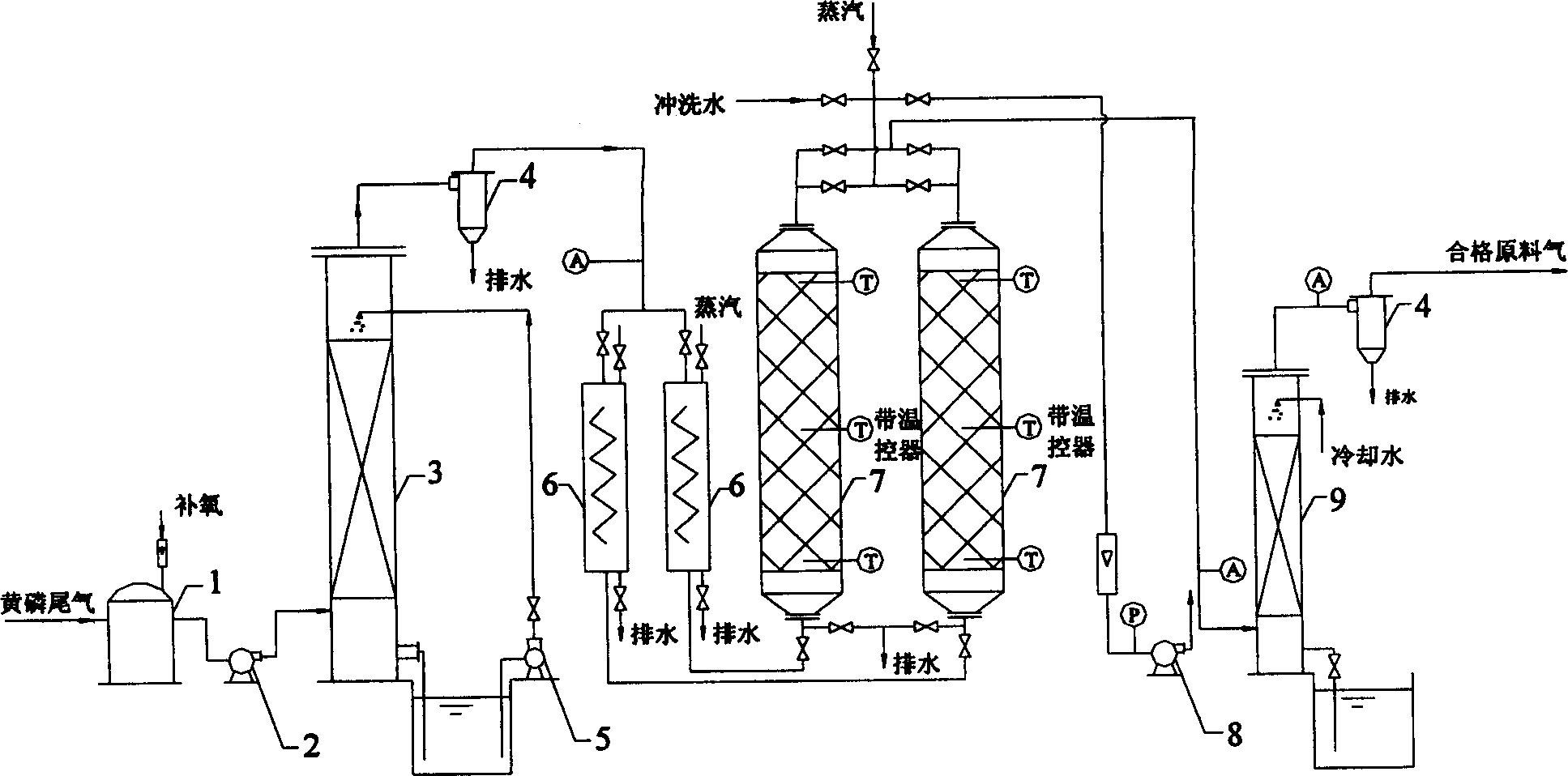

Method used

Image

Examples

Embodiment 1

[0044] The preparation of embodiment one (1) catalyst

[0045]Place activated alumina carrier in 0.2% lanthanum nitrate solution and immerse for 20 hours, age for 24 hours, evaporate to dryness on an electric constant temperature water bath, and finally put it into a muffle furnace for roasting at a constant temperature of 110°C 4 hours, then calcined at 500° C. for 6 hours, and dried at 110° C. for 4 hours to obtain a finished catalyst and fill it into a reactor to form a fixed bed for catalytic oxidation. (2) Exhaust gas purification conditions

[0046] The yellow phosphorus tail gas passes through the exhaust fan at a distance of 500 meters 3 (gas volume) / m 3 (Catalyst volume) The flow rate of hours goes through the alkali washing tower to remove carbon dioxide and some phosphorus, sulfur, and fluorine impurities, and then is heated to 80°C by a preheater, and oxygen is added at the same time, and passes through the fixed bed of the reactor from bottom to top. Here, phos...

Embodiment 2

[0048] The preparation of embodiment two (1) catalyst

[0049] Put the zeolite carrier in a ferrous sulfate solution with a concentration of 0.3% and immerse it for 24 hours. After aging for 24 hours, evaporate it to dryness on an electric constant temperature water bath, and finally put it into a muffle furnace for roasting. Constant temperature for 2 hours, then calcined at 550°C for 5 hours, and dried at 110°C for 4 hours to obtain a finished catalyst. (2) Exhaust gas purification conditions

[0050] The yellow phosphorus tail gas passes through the exhaust fan at a distance of 550 meters 3 (gas volume) / m 3 (Catalyst volume) The flow rate of hour is to remove carbon dioxide and some phosphorus, sulfur, and fluorine impurities through the alkali washing tower, then heat to 70°C through the preheater, supplement oxygen at the same time, and pass through the fixed bed of the reactor from bottom to top. Here, phosphorus and sulfur impurities are catalyzed and oxidized, and t...

Embodiment 3

[0052] Embodiment three (1) preparation of catalyst

[0053] The activated carbon carrier was immersed in 0.5% potassium hydroxide solution for 18 hours, and after aging for 24 hours, it was evaporated to dryness on an electric constant temperature water bath, and dried at 110°C for 6 hours to obtain a finished catalyst. (2) Exhaust gas purification conditions

[0054] The yellow phosphorus tail gas passes through the exhaust fan at a distance of 600 meters 3 (gas volume) / m 3 (Catalyst volume) The flow rate of hours goes through the alkali washing tower to remove carbon dioxide and some phosphorus, sulfur, and fluorine impurities, and then is heated to 110°C by a preheater, and oxygen is added at the same time, and passes through the fixed bed of the reactor from bottom to top. Here, phosphorus and sulfur impurities are catalyzed and oxidized, and the oxidized products such as phosphorus pentoxide, phosphorus trioxide, and sulfur are adsorbed on the surface of the catalyst. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com