Prepn of high-rate lithium ion battery cathode material

A lithium-ion battery and cathode material technology, applied in the field of high-rate lithium-ion battery cathode material preparation, to achieve the effects of narrow particle size distribution, good crystallinity, and uniform particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

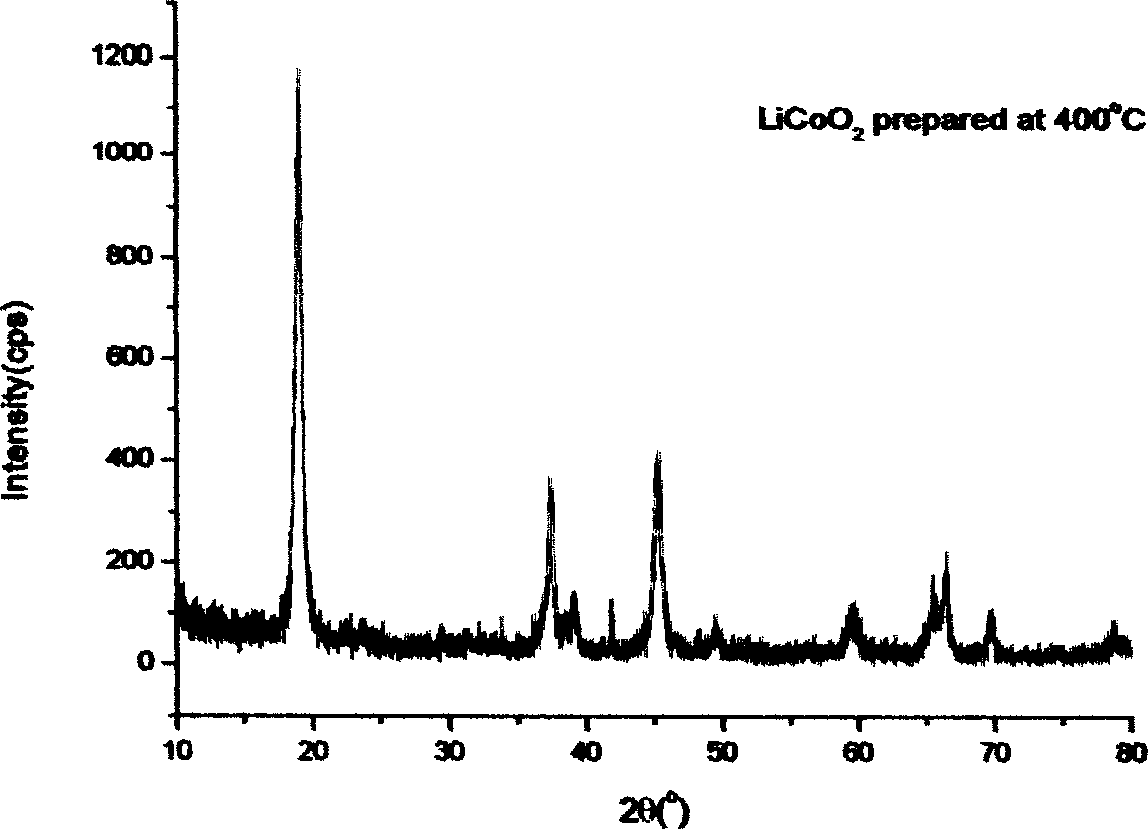

[0017] Accurately weigh 0.1mol LiNO 3 , 0.1mol Co(NO 3 ) 2 , dissolved in 100ml of absolute ethanol to obtain solution A; another accurately weighed 0.3mol NaOH, dissolved in 100ml of absolute ethanol to obtain solution B, and then solution B was dripped into solution A under strong mechanical stirring and ultrasonic vibration to obtain Viscous mixture. After standing still for 24 hours, use a high-speed centrifuge to separate the precipitate, dry it under vacuum at 120°C for 24 hours, and grind to obtain a brown loose reaction precursor. The precursor was calcined in a muffle furnace at 400°C for 10 hours to obtain a black solid product. Wash the product with deionized water until the pH is below 8, then wash and dehydrate with ethanol, at 120°C, in a vacuum of 10 -2 After vacuum drying under Torr and grinding, the final product LiCoO 2 . The particles are analyzed by transmission electron microscope, scanning electron microscope and XRD, and the particle diameter is le...

Embodiment 2

[0019] The brown loose reaction precursor obtained in Example 1 was calcined in an atmosphere sintering furnace at a temperature of 600° C. under an oxygen atmosphere for 5 hours to obtain a black solid product. Wash the product with deionized water until the pH is below 8, then wash and dehydrate with ethanol, at 120°C, in a vacuum of 10 -2 After vacuum drying under Torr and grinding, the final product LiNiO 2 . The product particles are analyzed by transmission electron microscope, scanning electron microscope and XRD, and the particle diameter is less than 30nm, which is square particles with uniform shape.

Embodiment 3

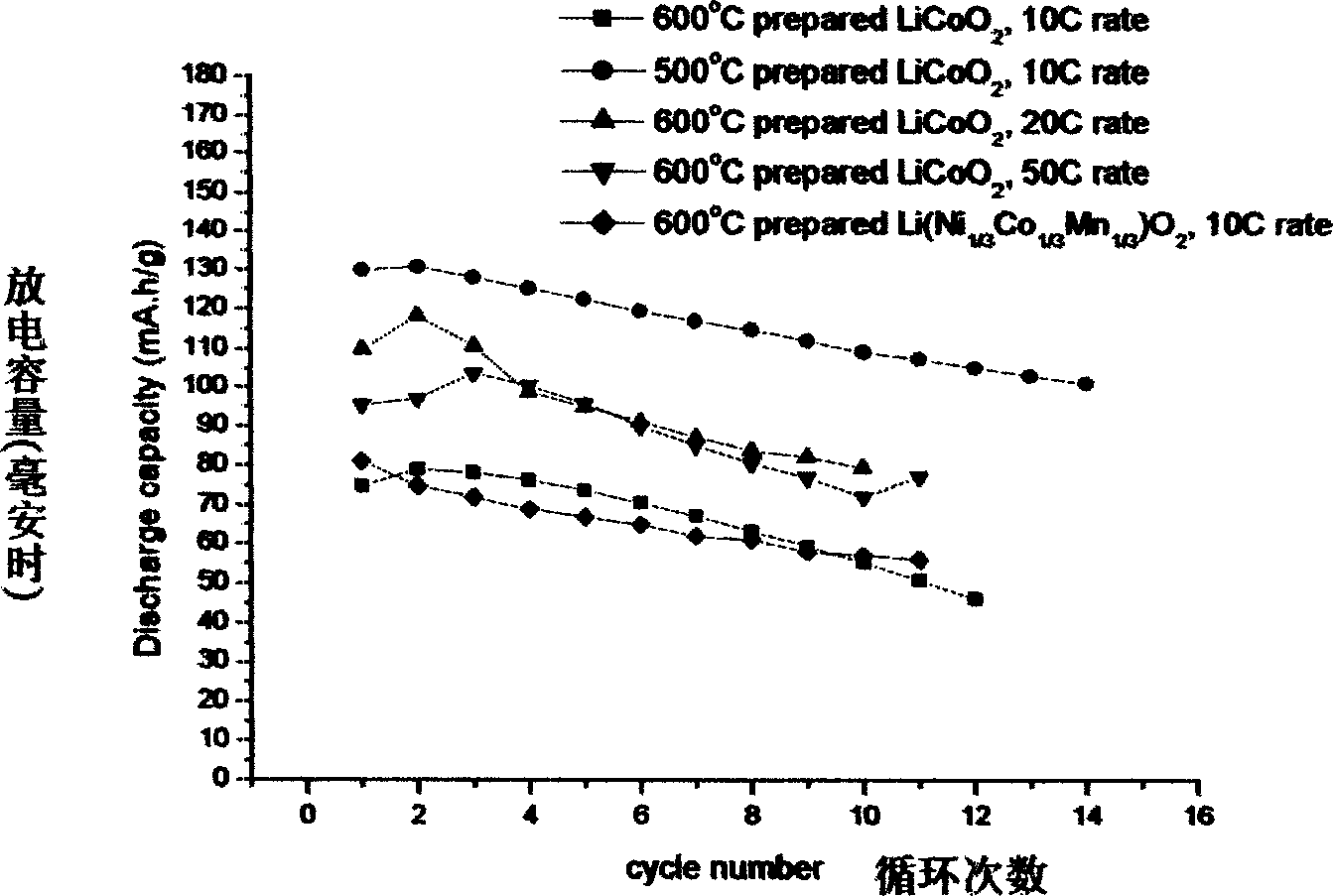

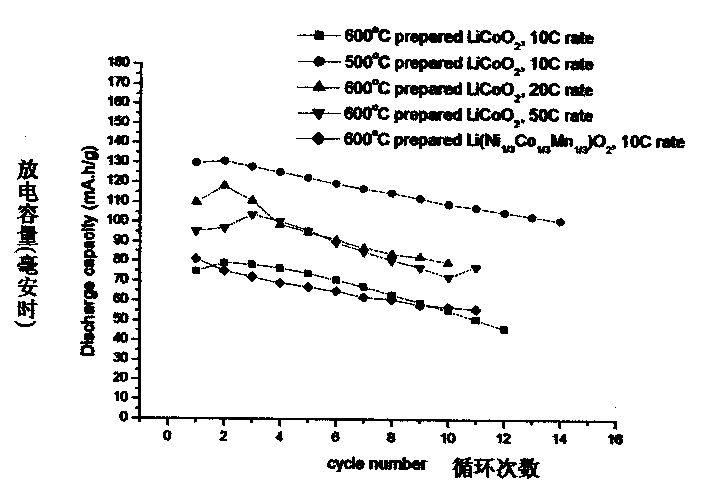

[0021] The brown loose reaction precursor obtained in Example 1 was calcined in a muffle furnace at a temperature of 500° C. for 10 hours to obtain a black solid product. Wash the product with deionized water until the pH is below 8, then wash and dehydrate with ethanol, at 120°C, in a vacuum of 10 -2 The final product was obtained after vacuum drying under Torr and grinding. The particles are analyzed by transmission electron microscope, scanning electron microscope and XRD, and the particle diameter is less than 80nm, which is sheet-like particles with uniform shape and single phase composition.

[0022] Weigh the product powder and carbon black according to the mass ratio of 6:3:1, polyvinylidene fluoride (PVDF), dissolve PVDF in a certain amount of N-methylpyrrolidone (NMP), and then mix the product powder with carbon black After adding, after 24 hours of high-speed mechanical stirring (600 rpm), a uniform slurry was obtained. The slurry is coated on the surface of a cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com