Process for chemical vapor phase depositing titaniam nitride containing silicon using titanium containing organic metal material

A deposition and process technology, applied in the field of chemical vapor deposition of titanium-containing silicon nitride TiSiN diffusion barrier layer, can solve the problems of poor material compatibility, rough surface, low coverage, etc., to improve the level of anti-electromigration , Uniform film thickness uniformity, and the effect of uniform resistance distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

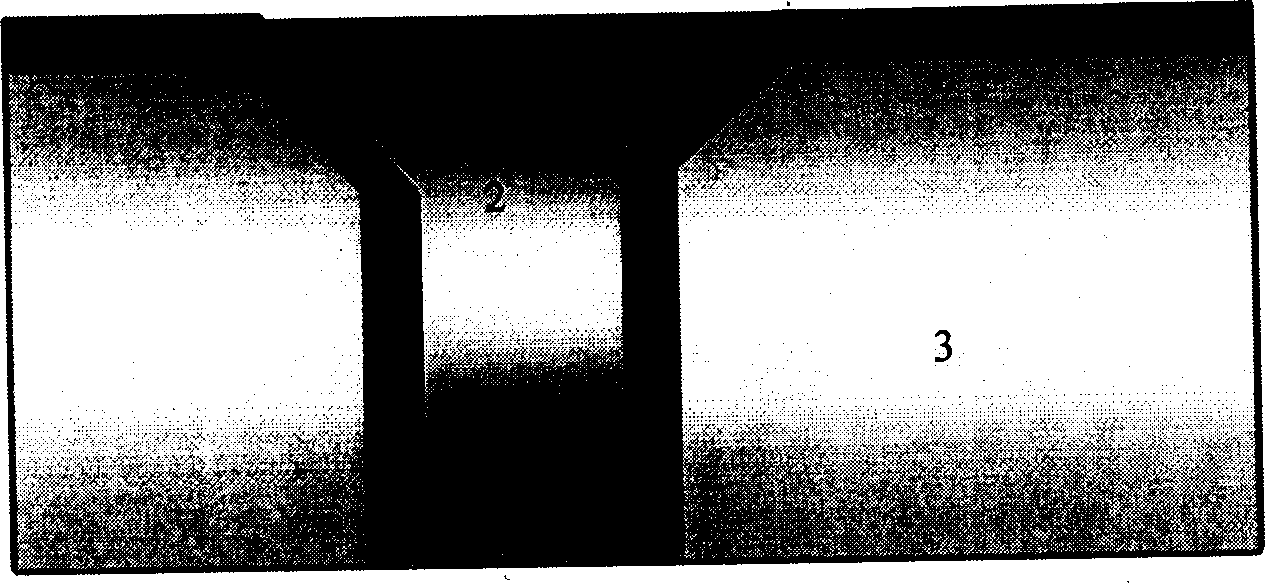

Image

Examples

Embodiment Construction

[0023] 1. Using multi-chamber CVD deposition equipment, such as the Endura TxZ & HP TxZ equipment of Applied Materials, using TDMAT to add methylsilane (3MS) or SiCH4, chemical vapor deposition of TiSiN thin film.

[0024] 2. First, raise the temperature of the silicon wafer to 450C under the condition that the vacuum is set to 5Torr.

[0025] 3. Next, use He 2 TiSiN films were deposited by thermal decomposition with chemicals TDMA and 5% methylsilane (3MS). At a deposition temperature of 450C, a low vacuum of 1.5Torr, a TDMAT flow rate of 225 sccm, a 3MS flow rate of 11 sccm, a SiCH4 flow rate of 4.5 sccm, and a He 2 The flow rate is 275sccm, N 2 The flow rate is 300 sccm, and the deposition time of each cycle is 15 seconds.

[0026] 4. In Situ H 2 -N 2Radio frequency plasma treatment reduces the content of impurities such as carbon, oxygen, and hydrogen in the TiSiN film deposited by CVD, reduces the resistivity, makes the TiSiN grains grow uniformly, densifies the TiSi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com