Piezoelectric element, ink-jet head, angular-rate sensor and its manufacturing method, ink-jet recorder

A piezoelectric element and piezoelectric layer technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, electrical components, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem of slow process PZT film , can not get an orientation film, crystal irregularity and other problems, to achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

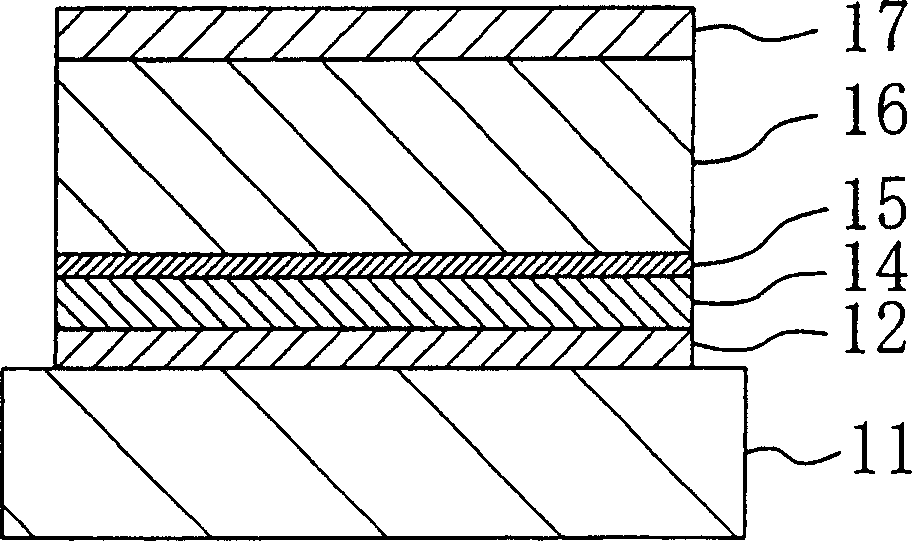

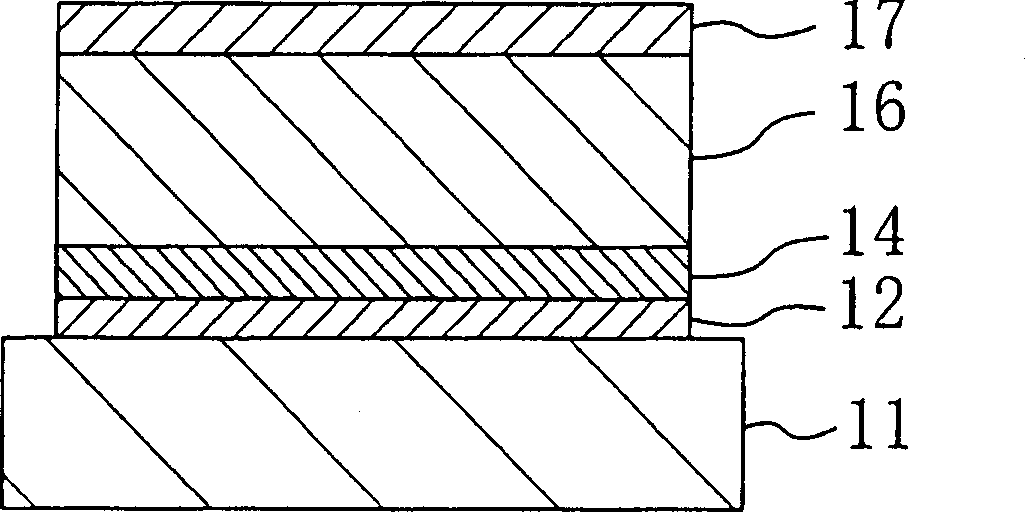

[0119] The material, film thickness, production method, etc. of each film in Example 1 are the same as those described in the above-mentioned embodiment. Cracks or film peeling were not seen in the respective films of the piezoelectric element of Example 1.

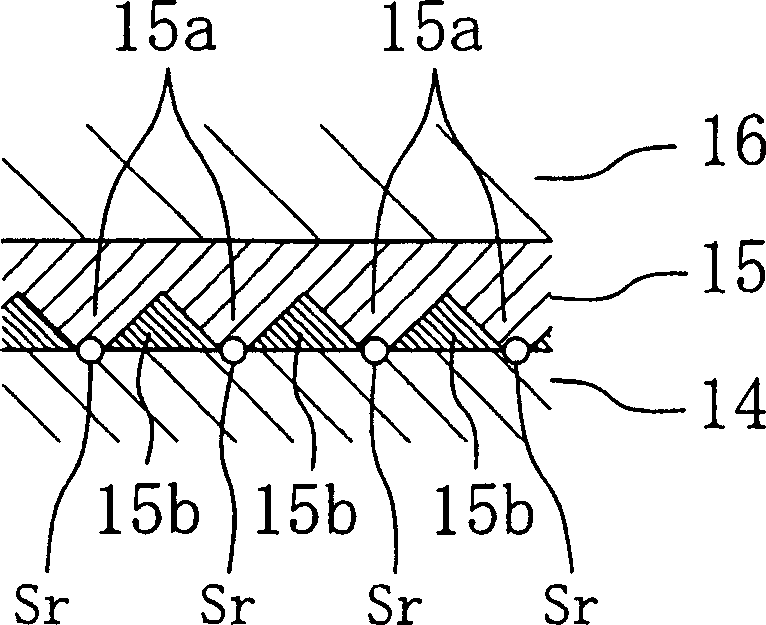

[0120] The crystal orientation and film composition of the piezoelectric layer before forming the second electrode layer were investigated. That is, according to the analysis by the X-ray diffraction method, the piezoelectric layer showed a (100) plane-oriented rhombohedral perovskite type crystal structure, and the (100) plane orientation degree was α=97%. In addition, as a result of composition analysis by an X-ray microanalyzer, the composition of the PZT film was the same as that of the target, and the Zr / Ti ratio was 53 / 47.

[0121] Next, the crystal orientation and film composition of the first electrode layer before forming the orientation control layer were studied. That is, as a result of analysis by the X-ray ...

Embodiment 2

[0126] In Example 2, the substrate is 0.25 mm thick and φ is 4 inches of stainless steel (SUS304), and a tantalum (Ta) film with a film thickness of 0.01 micron is used in the adhesion layer, and a film thickness of 0.01 micron is used in the first electrode layer. 0.25 micron Pt film containing 9 mol% of strontium oxide, 0.03 micron in film thickness, containing 17 mol% of lanthanum and 10 mol% of zirconium in the orientation control layer, and the lead content is excessive compared with the stoichiometric theoretical composition For the 6 mol% PLZT film, a PZT film (Zr / Ti=40 / 60) with a film thickness of 2.8 microns was used for the piezoelectric layer, and a Pt film with a film thickness of 0.1 micron was used for the second electrode layer.

[0127] Using a Ta target, the substrate was heated to 500° C. and a high-frequency power of 100 W was applied, and formed in an argon gas of 1 Pa for 1 minute to obtain the above-mentioned adhesion layer.

[0128] Using a Pt alloy targ...

Embodiment 3

[0139]In Example 3, the substrate is barium borosilicate glass (100 mm square size) with a thickness of 0.5 mm, and a nickel (Ni) film with a film thickness of 0.005 microns is used for the adhesion layer, and a film of nickel (Ni) is used for the first electrode layer. A 0.15 micron thick iridium (Ir) film containing 18 mol% Ca was used in the orientation control layer. The orientation control layer was made of strontium titanate containing 18 mol% Sr and 15 mol% Zr with a lead content equal to A film composed of a solid solution of PZT with an excess of 16 mol% of the stoichiometric composition, a PZT film (Zr / Ti=60 / 40) with a film thickness of 2.5 microns is used for the piezoelectric layer, and a PZT film (Zr / Ti=60 / 40) is used for the second electrode layer Pt film with a film thickness of 0.01 µm.

[0140] Using a Ni target, the substrate was heated to 300° C., and a high-frequency power of 200 W was applied, and formed in an argon gas of 1 Pa for 1 minute to obtain the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com