Synthesis of titania with high specific surface area

A technology with high specific surface area and synthesis method, which is applied in the field of titanium oxide synthesis with high specific surface area, can solve the problems of no specific surface area data and photocatalytic activity, difficult removal of template agent, poor effect of organic matter, etc., and achieve stable organic matter activity and low cost , The effect of high activity of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

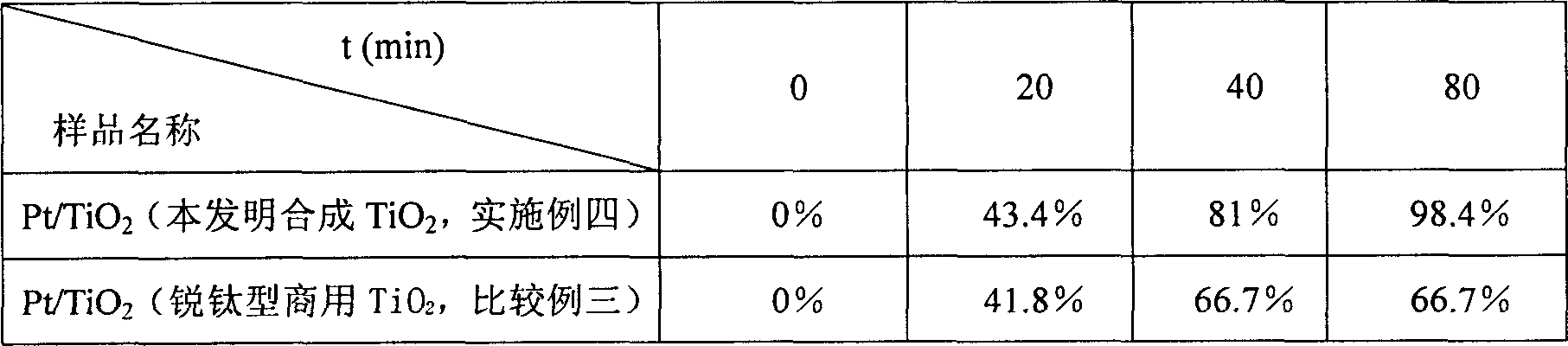

Examples

Embodiment 1

[0017] ① Anatase TiO 2 , Industrial Grade K 2 CO 3 (purity 98wt%), H 2 O is uniformly mixed, where TiO 2 / K 2 O=2.5 (mol ratio), water content 20wt%; ②Apply the mixed reaction materials evenly on the alumina backing plate, the reaction temperature is 1000°C, the reaction time is 2 hours, and the sintered products are potassium dititanate and tetratitanic acid Potassium mixed crystals; ③After the sintered product is dispersed in water, it is placed in an aqueous solution of 50°C and 5 times of pH=8 to react for 8 hours. The amount is less than 5wt% of the product weight; ④Washing, filtering, and drying at 20-50°C for 12 hours to obtain a hydrated product with a specific surface area of 268m 2 / g; ⑤ Crystallized in air at 500°C for 2 hours, the obtained TiO 2 The crystal form is anatase and monoclinic TiO 2 Mixed crystals, the morphology is whisker-like, the specific surface area is 105m 2 / g.

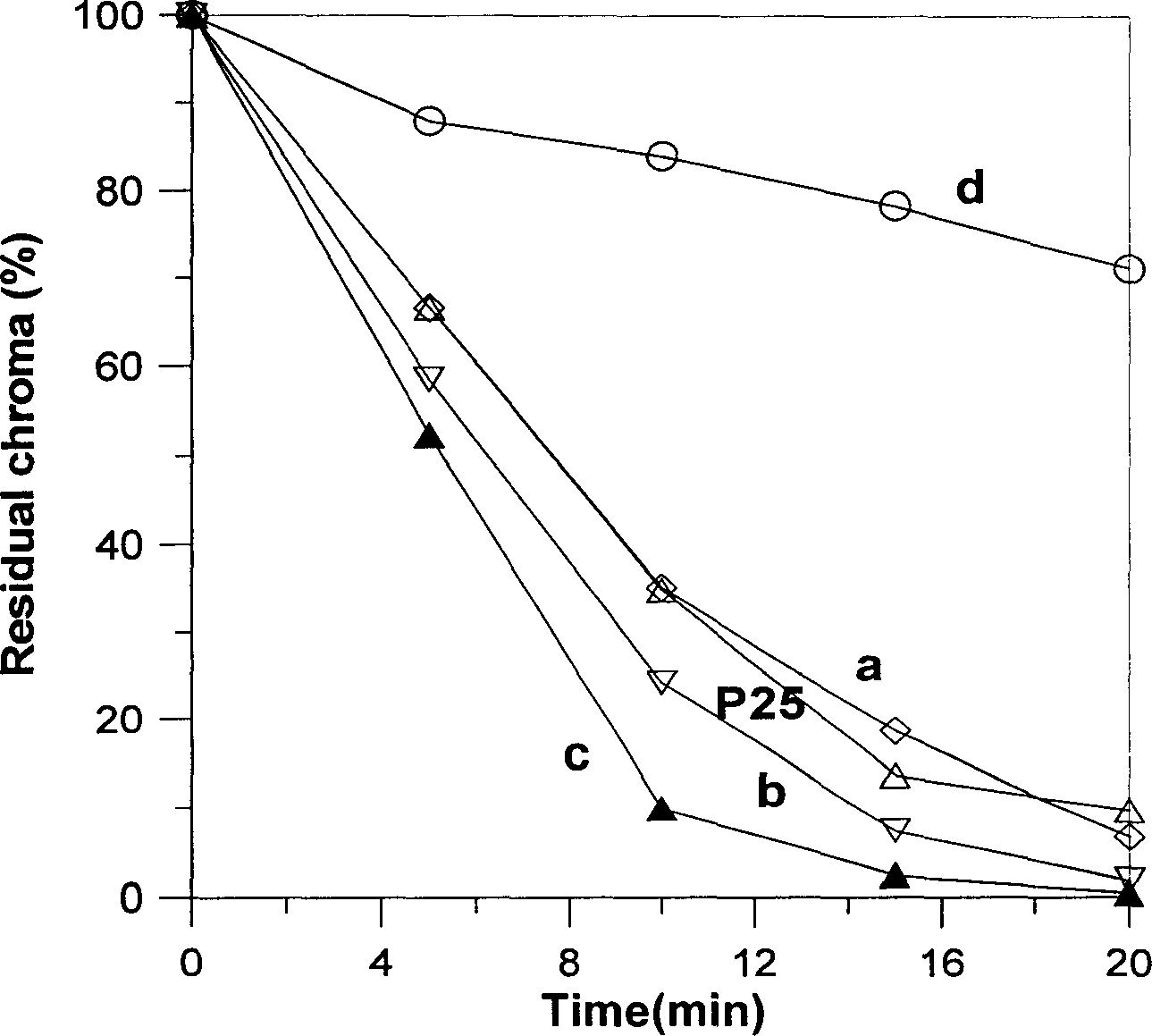

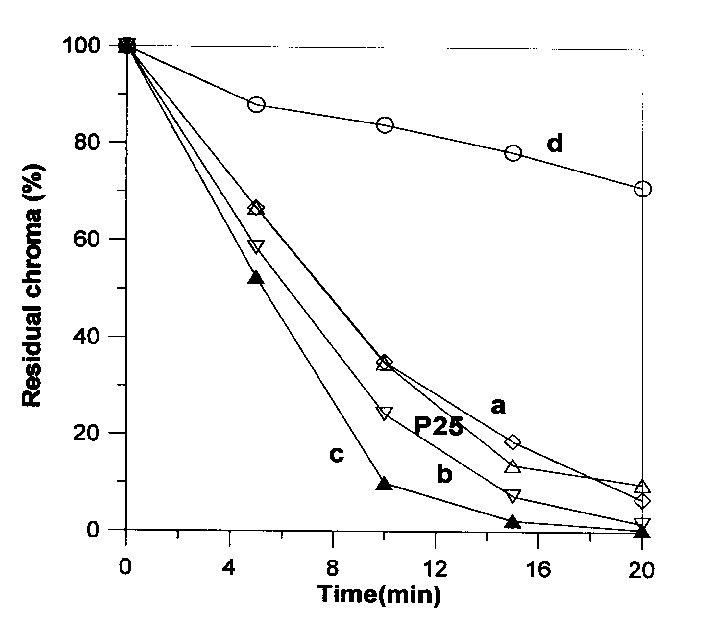

[0018] The photocatalytic experiment uses a cylindrical photochemical rea...

Embodiment 2

[0020] ①Amorphous titanium dioxide, potassium nitrate, H 2 O is uniformly mixed, where TiO 2 / K 2 O=3 (mol ratio); ②Apply the mixed reaction materials evenly on the alumina backing plate, the reaction temperature is 810°C, the reaction time is 1 hour, and the sintered product is potassium dititanate; ③After the sintered product is dispersed in water, Placed at 60° C., 20 times the potassium nitrate solution containing K+ ion concentration of 2mol / L to react for 10 hours, then stirred in an aqueous nitric acid solution with a pH of 1 for 8 hours, until the potassium content in the solid phase was less than 5wt% of the product weight; ④ Wash with water, filter, and dry at 20-50°C for 12 hours to obtain a hydrated product with a specific surface area of 200m 2 / g; ⑤ hydrothermal crystallization at 200°C for 1 hour to obtain anatase TiO 2 and a small amount of rutile TiO 2 , the shape of the product is granular, the equivalent diameter is 1-5μm, and the specific surface area...

Embodiment 3

[0022] Anatase TiO 2 , Industrial Grade K 2 CO 3 (purity 98wt%), H 2 O is uniformly mixed, where TiO 2 / K 2 O=3 (mol ratio), water content 30wt%; ②Apply the mixed reaction materials evenly on the alumina backing plate, the reaction temperature is 1000°C, the reaction time is 3 hours, and the sintered products are potassium dititanate and tetratitanic acid Potassium mixed crystal; ③ After the sintered product is dispersed in water, it is placed in an aqueous solution of 80°C and 40 times of pH = 10 to react for 12 hours. The amount is less than 5wt% of the product weight; ④Washing, filtering, and drying at 20-50°C for 12 hours to obtain a hydrated product with a specific surface area of 150m 2 / g; ⑤ In a round-bottomed flask with a condensing reflux device, dehydrate at a constant temperature of 150-250°C in glycerin (normal pressure) for 24 hours, filter, wash with ethanol, and dry at 80°C. The crystal form of the obtained product is eight Titanic acid type, the shape ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com