Preparation process of polyester carbonate with high molecular weight whole alternant structure

A polycarbonate, alternating structure technology, applied in the field of polymer materials, can solve the problems of long reaction time, low carbonate units, low catalyst activity, etc., and achieve high selectivity of polymerization products, mild reaction conditions, and high catalyst activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

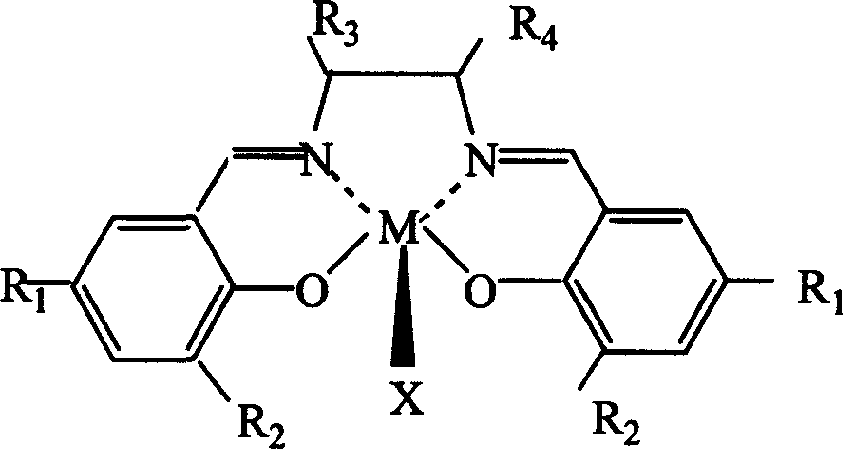

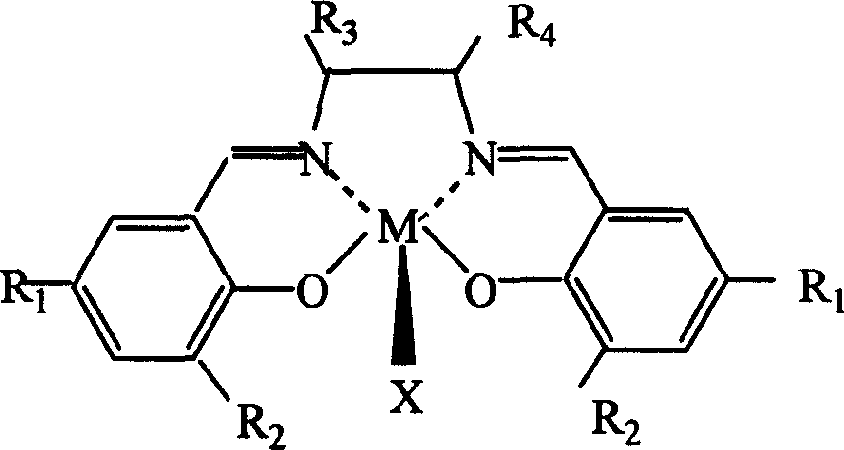

[0025] In a stainless steel autoclave with an effective volume of 200ml, add in the following order at ambient temperature: 0.5×10 -3 mole SalenCoX(R 1 = R 2 =t-Bu,R 3 , R 4 Yes-(CH 2 ) 4 -, X is 2,4-dinitrophenol oxyanion), 0.5×10 -3Mole of tetra-n-butylammonium iodide, 1 mole of propylene oxide, and then pass through carbon dioxide gas and maintain a constant pressure of 2.0MPa. Control the temperature at 25°C, react under magnetic stirring for 4 hours, slowly release unreacted carbon dioxide in the autoclave, collect unreacted propylene oxide in a cold trap at -20°C under low pressure, and then add a certain amount of methanol / chloroform The mixture dissolves the polymer, and then a large amount of ether is added to precipitate polycarbonate. It was filtered, washed several times with ether, and dried in vacuo to constant weight to obtain 38 g of polypropylene carbonate as a white solid. The average molecular weight of this polymer measured by gel permeation chromat...

Embodiment 2

[0027] In the same apparatus as used in Example 1, under the same conditions, only tetra-n-butylammonium bromide was used instead of tetra-n-butylammonium iodide. After reacting at 25° C. for 4 hours, 41 grams of polypropylene carbonate was obtained with a molecular weight of 32,000 and a molecular weight distribution of 1.53, and the carbonate units in the polymer exceeded 99%.

Embodiment 3

[0029] In the same apparatus as used in Example 1, under the same conditions, only tetra-n-butylammonium chloride was used instead of tetra-n-butylammonium iodide. After reacting at 25° C. for 4 hours, 34 g of polypropylene carbonate was obtained, the molecular weight was 32300, the molecular weight distribution was 1.55, and the carbonate units in the polymer exceeded 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com