Multiple step method for preparing intelligence type degradable macromolecular microgel

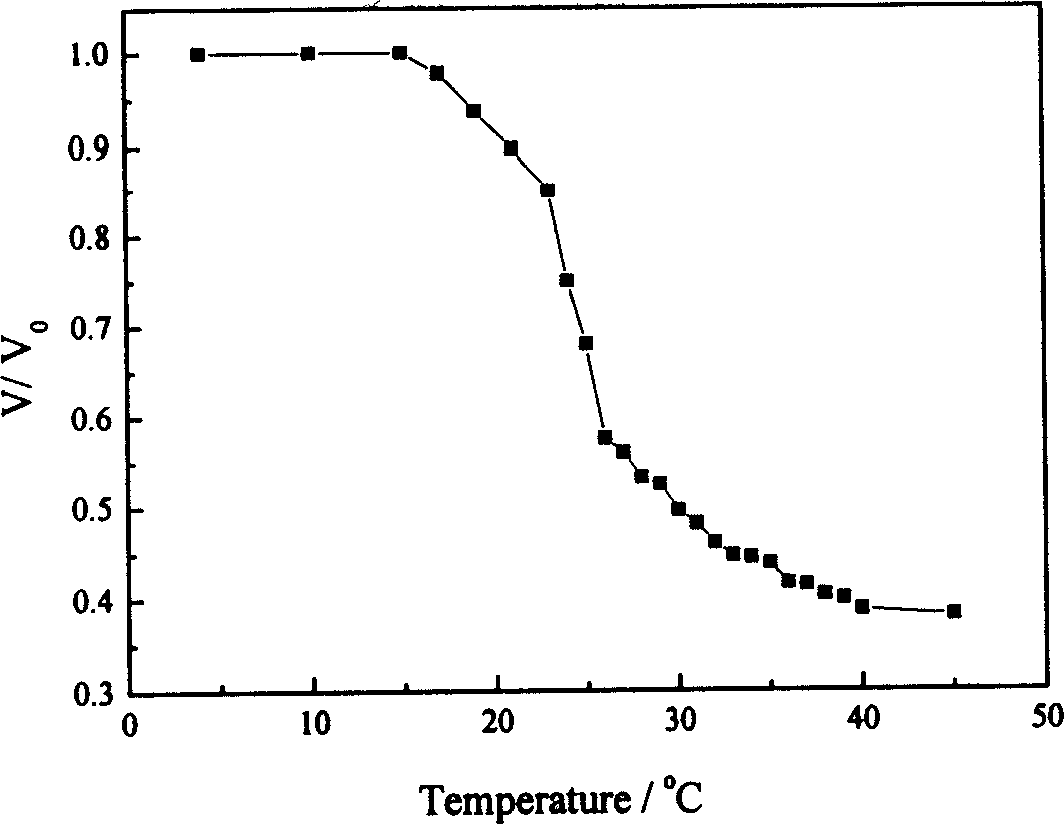

A microgel and macromonomer technology, applied in the field of microgel preparation, can solve problems such as unfavorable protein activity, and achieve the effects of remarkable temperature sensitivity, wide application range and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 20g of PEO 100 -PPO 65 -PEO 100 1.84g of lactide and 1.3ml of 10mg / ml stannous octanoate in benzene solution were packed in a 50ml pre-vacuum-dried ampoule tube, and the ampoule tube was evacuated in a 60°C oil bath for 6hr to remove volatile matter. Replace with argon several times during this period, then heat-seal the ampoule under vacuum, react in an oil bath at 150°C for 24 hours, dissolve with dichloromethane after cooling, and then precipitate with excess anhydrous ether to remove excess stannous octoate , obtained by suction filtration to obtain F127 / oligoester copolymer, and vacuum-dried at room temperature for 2-3 days. The dichloromethane solution of the copolymerization product is reacted with acryloyl chloride (molar ratio: 1:10), filtered after the reaction, and the filtrate is precipitated in anhydrous ether (-10~0°C), the precipitate is collected, and vacuum-dried to obtain a macromonomer (PEO 100 -PPO 65 -PEO 100 )-LA 8 -DA.

[0041] Add Span 80...

Embodiment 2

[0044] Same operation as in Example 1, the molar ratio of the reactant feed is PEO 129 -PPO 56 -PEO 129 : ε-caprolactone: stannous isooctanoate=1:8:0.02, after mixing evenly, vacuumize at 60°C for 6 hours to remove volatile matter, then replace with inert gas (nitrogen or argon) several times, and finally The ampoule was heat sealed under vacuum (0.1 mmHg). The copolymerization reaction was carried out at 150° C. for 24 hours. The dichloromethane solution of the copolymerization product is reacted with methacryloyl chloride (molar ratio: 1:20), filtered after the reaction, and the filtrate is precipitated in anhydrous ether (-10~0°C), the precipitate is collected, and vacuum-dried to obtain a macromolecule Monomer (PEO 129 -PPO 56 -PEO 129 )-CL 4 -DMA.

[0045] Add Span 80 and Tween 80 (weight ratio is 84: 16) and cyclohexane successively in the four-necked flask of nitrogen protection, (the weight ratio of emulsifier and cyclohexane is 10%), stir in ice bath , the st...

Embodiment 3

[0047] Same operation as in Example 1, successively add Span 80 and xylene in a four-necked flask protected by nitrogen, (the weight ratio of emulsifier to xylene is 12%), stir in an ice bath, and the stirring speed is 250 rpm , drop 20% concentration of (PEO 103 -PPO 39 -PEO 103 )-(CL 4 -LA 4 )-DA macromonomer aqueous solution (containing 3% ammonium persulfate and 2.5% ascorbic acid by macromonomer weight), 1-2 drops per second, and the weight ratio of xylene and macromonomer aqueous solution is 10:1. After stabilizing in an ice bath for 20 minutes, heat the water bath to 50°C, stop stirring after 2 hours, filter with a sieve while it is hot, wash with deionized water, and store in a refrigerator to obtain a microgel with a particle size range of 30 -400 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com