Series special fertilizer prepared by urban sludge and its preparation method

A technology of municipal sludge and special fertilizer, applied in the directions of sewage/sludge fertilizer, sludge treatment, chemical instruments and methods, etc., to achieve the effect of wide application, enhanced stress resistance and early maturity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

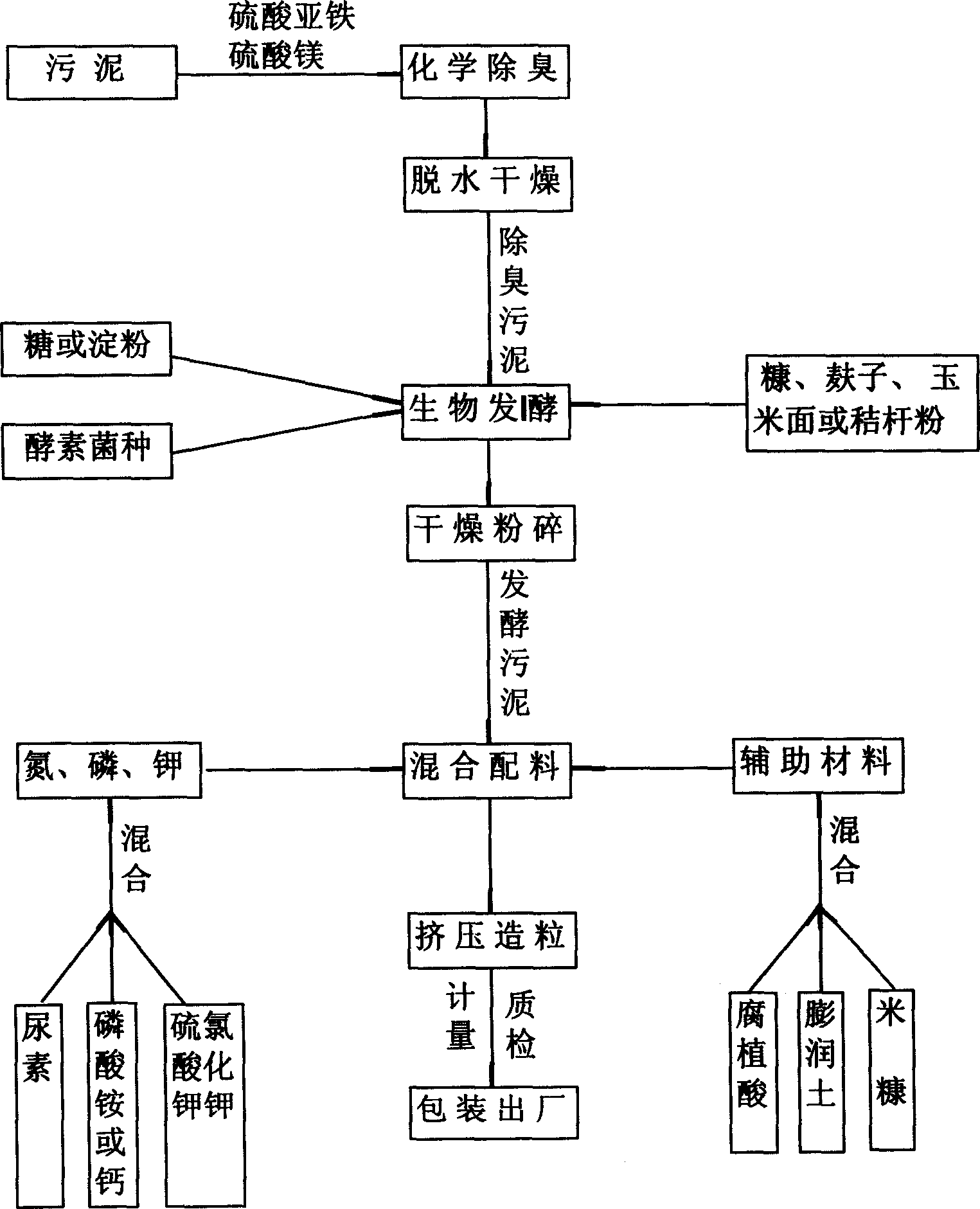

[0027] Embodiment 1: According to figure 1 The process shown

[0028] a. Do chemical deodorization treatment to the sludge first, and add 0.5% ferrous sulfate (FeSO 4 .7H2o) and 0.1% magnesium sulfate (MgSO 4 ), stir evenly after mixing, let stand for 1-2 hours, and then transport the odorless sludge to a dry site for precipitation drying.

[0029] b. Dehydration and drying: the drying field uses plastic greenhouses, spreads the deodorizing sludge into a 15cm thickness in the greenhouse, in a wave shape, and naturally dries at room temperature until the water content is 40-50%, and then becomes the deodorizing sludge for use;

[0030] c. Biological fermentation: Weigh 1000kg (200 parts) of deodorized sludge with a water content of 40-50%, 50kg (10 parts) of rice bran, 10kg (2 parts) of bran, 5kg (1 part) of brown sugar and enzyme strains (Commercially available) 5kg (1 part) mixed and stirred evenly, spread out on the cement floor into a long mountain shape with a width of ...

Embodiment 2

[0038] Embodiment 2, according to figure 1 The process shown

[0039] a. Chemical deodorization: Add ferrous sulfate (FeSO 4 .7H2o) and 0.3% magnesium sulfate (MgSO 4 ), stir evenly after mixing, and others are with embodiment 1;

[0040] B, dehydration drying: with embodiment 1;

[0041] c, biological fermentation: 1000kg of deodorized sludge with a water content of 40-50%, add 60kg (12 parts of straw powder, 6.5kg (1.3 parts) of white sugar and 7.5kg (1.5 parts) of enzyme bacteria (commercially available) , after fully stirring evenly, with embodiment 1;

[0042] D, dry crushing: with embodiment 1;

[0043] e, mixed ingredients: take 50kg of urea, 20kg of monoammonium phosphate, and 20kg of potassium sulfate to make mixed potassium sulfate for subsequent use;

[0044] Take by weighing 45kg of humic acid, 20kg of bentonite, 35kg of rice bran and mix the auxiliary materials prepared by stirring evenly for subsequent use;

[0045] Weigh 45kg of powdery fermented sludge, ...

Embodiment 3

[0048] Embodiment 3, according to figure 1 The process shown

[0049] a. Chemical deodorization: Add ferrous sulfate (FeSO 4 .7H2o) and 0.2% magnesium sulfate (MgSO 4 ), stir evenly after mixing, and others are with embodiment 1;

[0050] B, dehydration drying: with embodiment 1;

[0051] c, biological fermentation: be 40-50% deodorizing sludge 1000kg with water content, add 55kg (11 parts) cornmeal, 7.5kg (1.5 parts) starch and 7.5kg (1.5 parts) ferment bacterial classification (commercially available), Fully stir evenly, other is with embodiment 1;

[0052] D, dry crushing: with embodiment 1;

[0053] E, mixing ingredients: take by weighing 35kg of urea, 35kg of monoammonium phosphate, and 30kg of potassium sulfate to make mixed potassium sulfate for subsequent use;

[0054] Take by weighing 35kg of humic acid, 25kg of bentonite, 40kg of rice bran and stir the auxiliary material prepared evenly for subsequent use;

[0055] Weigh 55kg of powdery fermented sludge, add 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com