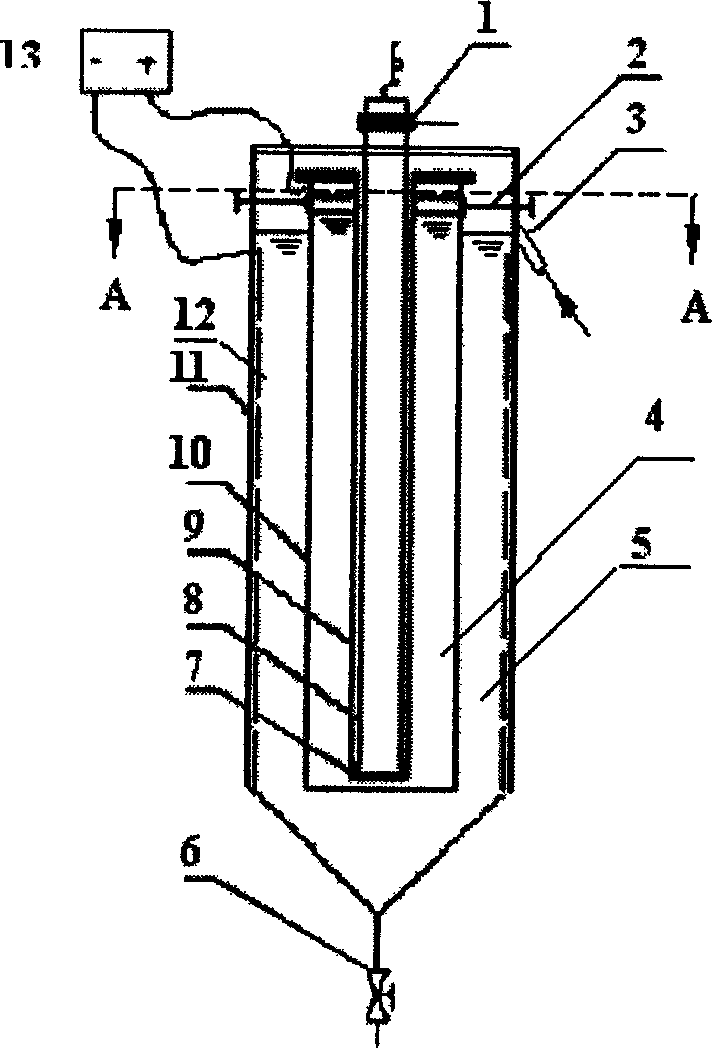

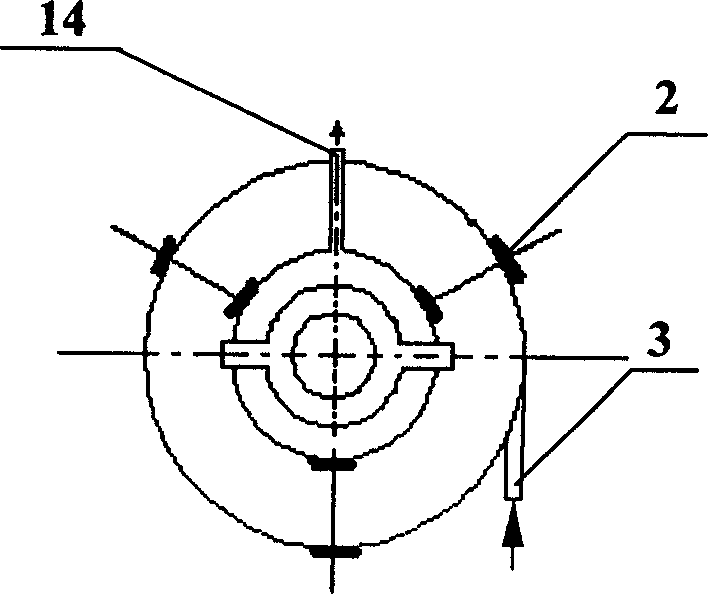

Equipment and method of homogeneous photochemistry and electrochemical oxidation unit for processing organic waste water

A technology for organic wastewater and oxidation treatment, applied in the direction of electrochemical water/sewage treatment, light water/sewage treatment, etc., to achieve long hydraulic retention time, promote photochemical oxidation, and ensure efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0036] Add sodium chloride to the wastewater containing 1mM p-nitrophenol to be treated, so that the concentration of sodium chloride is 5g / L, then add 5mM hydrogen peroxide, and adjust the pH of the wastewater to 3.0, and control the flow rate of the wastewater to 20mL / s At the same time, the ultraviolet lamp with a power of 8W and the electrochemical DC power supply were connected, the current was adjusted to 1.0A, and the treatment was performed for 60 minutes. Under the action of photoelectric integration, the removal rate of chemical oxygen demand (COD) is 32.2%. However, with single photochemical oxidation or electrocatalytic oxidation, the COD removal rates are 11.5% and 18.9%, respectively. Therefore, the photoelectric integration degradation effect of the present invention is better than the sum of the two single methods. This shows that the combined process of the present invention has a certain synergistic effect.

example 2

[0038] Add sodium sulfate to the wastewater containing 1mM p-nitrophenol (PNP) to be treated to make the concentration of sodium sulfate 3g / L, then add 0.5mM iron sulfate, and adjust the pH of wastewater to 3.0, and control the flow of wastewater to 20mL / L s, turn on the ultraviolet lamp with a power of 8W and the electrochemical DC power supply at the same time, adjust the current to 0.5A, and treat for 120min. The results show that the apparent kinetic constant k for PNP removal in optoelectronic integration is 1.07 × 10 -3 the s -1 , much larger than the kinetic constant (0.19×10 -3 the s -1 ) and the kinetic constant of the individual electrocatalytic oxidation (0.36×10 -3 the s -1 ) shows that the present invention has an obvious synergistic effect on the removal of PNP, and its synergistic effect factor is 123%.

example 3

[0040] Add sodium sulfate in the waste water that contains 1mM p-nitrophenol (PNP) to be treated, make its sodium sulfate concentration be 3g / L, add the hydrogen peroxide of 0.5mM iron sulfate and 5mM again, and regulate waste water pH3.0, Control the waste water flow rate to 30mL / s, simultaneously turn on the ultraviolet lamp with the power of 8W and the electrochemical DC power supply, adjust the current to 0.5A, and treat for 120min. In the single photochemical oxidation, except that no direct current is passed, the rest is the same as the photoelectric integration. In the single electrochemical oxidation, except that ferric sulfate and hydrogen peroxide are not added, and the ultraviolet lamp is not turned on, the remaining conditions are the same as those of photoelectric integration. The removal results of COD by the above three treatment methods are shown in Table 1:

[0041] time (minutes)

[0042] It can be seen from the above table that photoelectric integ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com