Fire-retarded material of polypentaerythritol kind phosphate ester melamine salt expended type and its preparation process

A technology of phosphate melamine salt and phosphate melamine, which is applied in the field of flame retardant materials, can solve problems such as unsatisfactory and oxygen index retention, and achieve the effects of good moisture resistance, small amount of addition, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

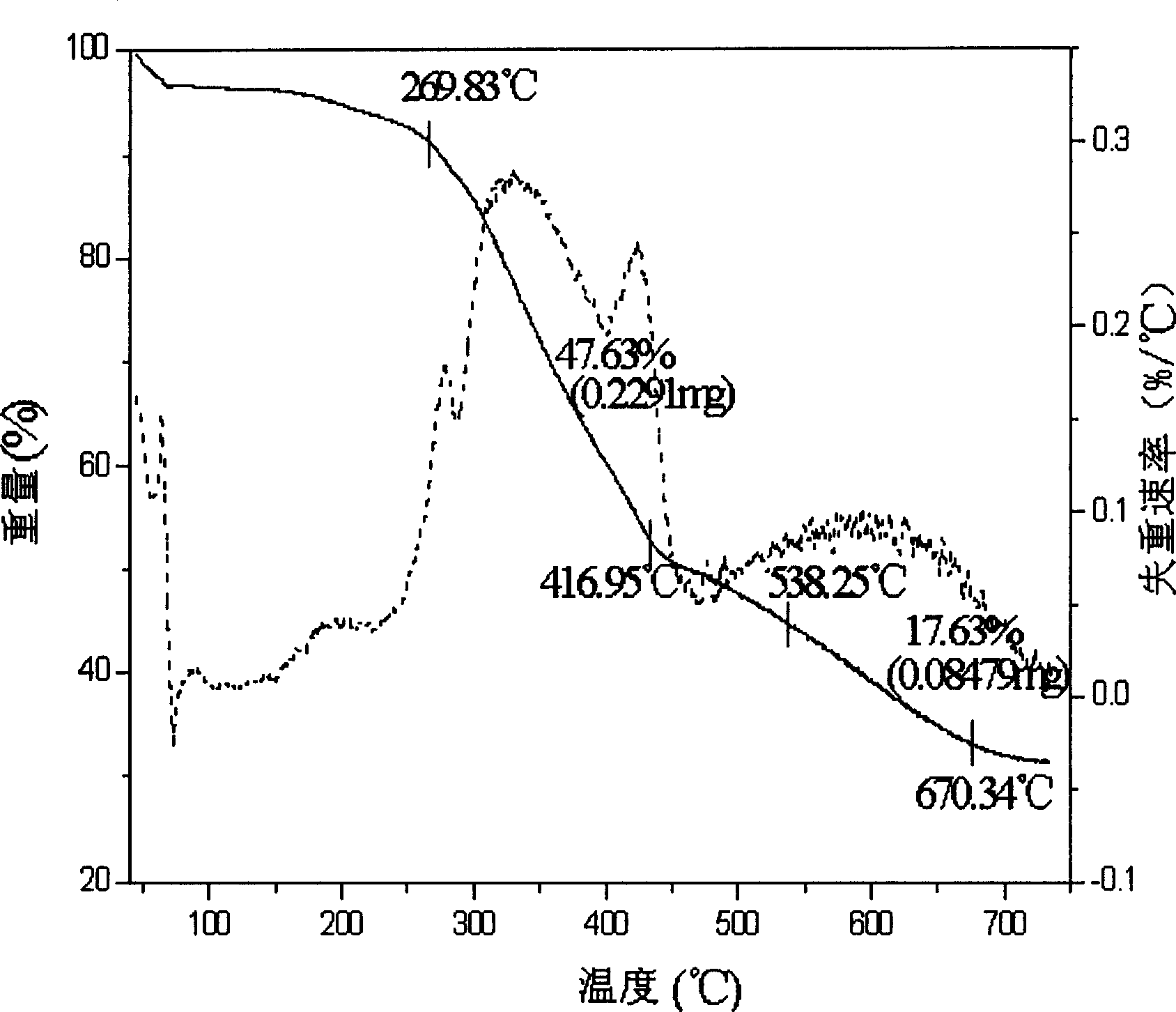

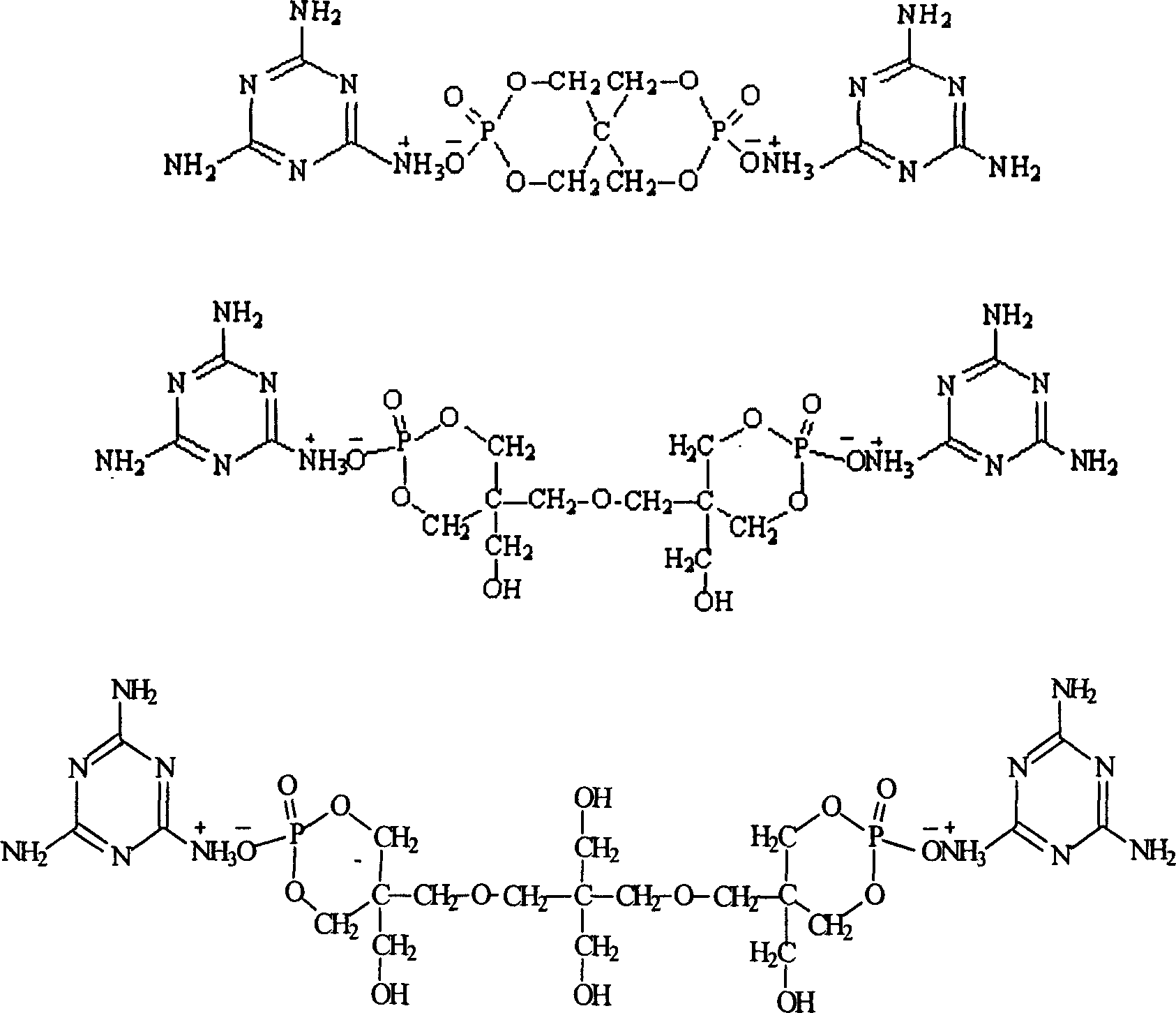

[0061] Add 190g of pentaerythritol, 25g of water, and 100g of phosphorus pentoxide into a three-necked flask, place it in an oil bath at 75°C, and stir vigorously for 6 hours; add 126g of melamine, and perform homogenization under rapid stirring. Then put it into a muffle furnace for reaction at a temperature of 250° C., keep it warm for 45 minutes, take it out, and crush it.

[0062] After the polypropylene is plasticized on a two-roller plastic mixer, add 20% flame retardant, knead at 160°C for 10 minutes to make it evenly mixed, and hydraulically form it on a hot press at 185°C. The oxygen index of flame-retardant polypropylene was measured according to GB / T 2406-93, and the test result showed that the oxygen index was 23.

Embodiment 2

[0064] Add 180g of dipentaerythritol, 50g of water, and 100g of phosphorus pentoxide into a three-neck flask, place in an oil bath at 90°C, and stir vigorously for 4 hours; add 126g of melamine, and perform homogenization under rapid stirring. Then put it into a muffle furnace for reaction at a temperature of 250° C., keep it warm for 45 minutes, take it out, and crush it. According to the method of Example 1, the ratio of polypropylene to the dipentaerythritol-based phosphate melamine salt flame retardant obtained above was 75:25, and a flame-retardant polypropylene sample was prepared, and its flame-retardant performance was measured. The test result showed that the oxygen index was 29. According to UL94-1996, the horizontal and vertical flame retardant performance of flame retardant polypropylene is measured, the vertical combustion performance reaches 94V-0 level, and the horizontal combustion performance is HB.

Embodiment 3

[0066] 100 grams of melamine, 250 grams of formaldehyde (36%) are added successively in the round bottom flask that reflux condenser is housed, then add the water of 400 grams, adjust the pH value of solution with 20% sodium hydroxide solution to be about 9, Then the temperature was raised to 80°C, and after the solution became clear, the temperature was continued for 15 minutes to obtain a melamine-formaldehyde polymer.

[0067] In a three-necked flask equipped with a reflux condenser and vigorously stirred, add a certain amount of toluene, then add 500 grams of dipentaerythritol phosphate melamine salts obtained by the above reaction (prepared according to Example 2 and pulverized to more than 500 orders) ) and 40 grams of styrene-maleic anhydride copolymer resin, stirred vigorously at a speed of 3000r / min for 15min, then heated up to 60-70°C, added 500 grams of melamine-formaldehyde prepolymer, and stirred at a speed of 1000r / min After 2h, cool slowly at room temperature. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com