Process for preparing ceftriaxone sodium

A ceftriaxone sodium and preparation process technology, applied in the field of compound preparation, can solve the problems of large solvent usage, high production cost, and long production cycle, and achieve the advantages of less solvent usage, low production cost, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

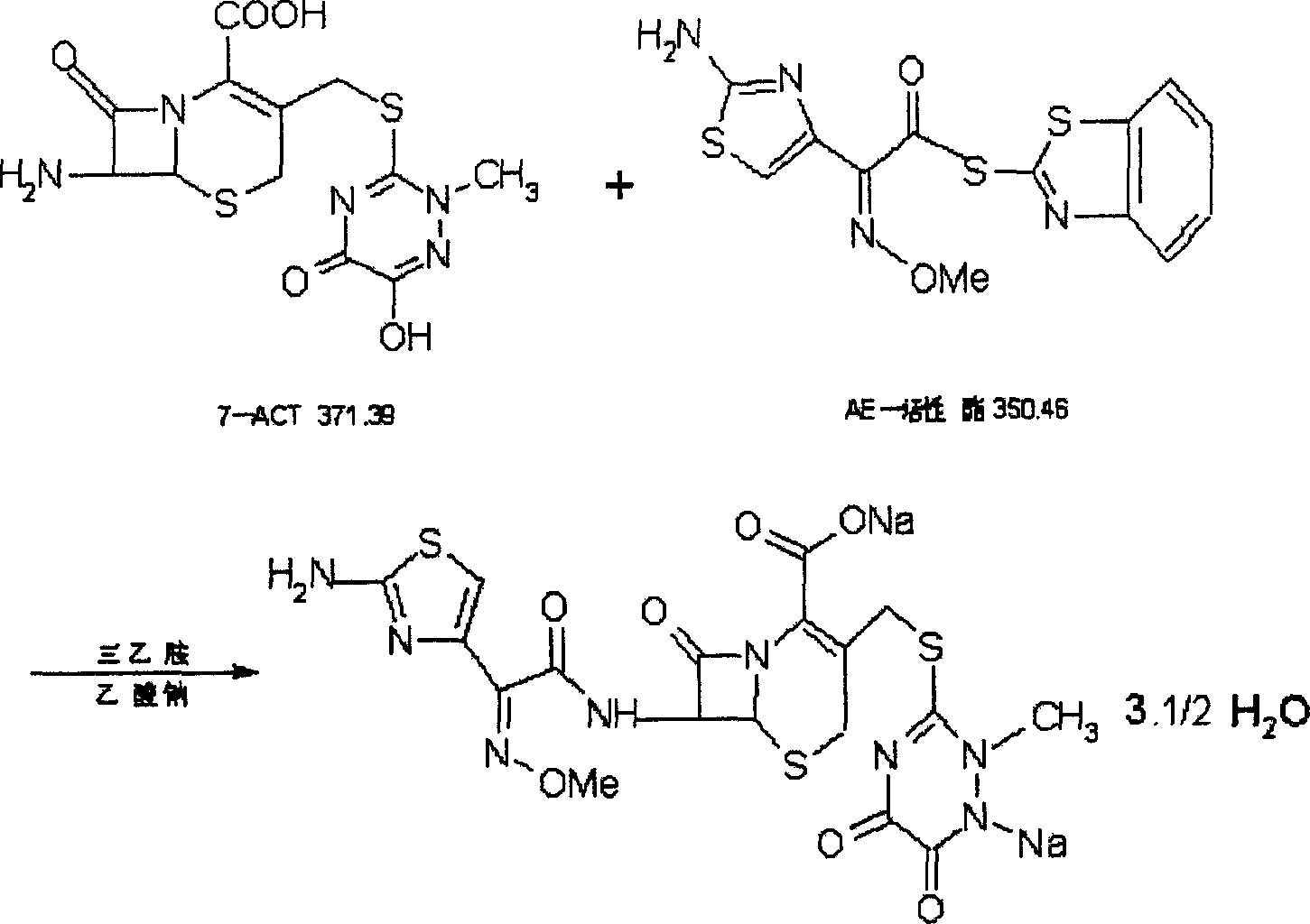

Image

Examples

Embodiment 1

[0022] The preparation technology of ceftriaxone sodium of the present invention is recorded as follows by operation time:

[0023] 7:30 Add 50ml of dichloromethane, 50ml of ethanol, 18ml of triethylamine, and 5ml of water into the three-necked bottle, stir and cool down under nitrogen protection;

[0024] 7:32 At 5°C, add 20g of 7-ACT, 20g of AE-active ester, and 0.5g of sodium bisulfite antioxidant:

[0025] 7:35 stirring reaction, temperature 6°C;

[0026] 9:30 The reaction was clarified, diluted with 30ml of ethanol, and filtered;

[0027] 9:45 Add sodium acetate aqueous solution dropwise;

[0028] 9:50 The solution is slightly muddy, add ceftriaxone sodium powder seed crystals to grow crystals;

[0029] 10:20 Add acetone dropwise to crystallize, share 400ml of acetone, temperature 10°C;

[0030] 11:50 Suction filtration to obtain a crystallization filter cake, washed with acetone;

[0031] 12:25 50 ℃ hot air drying;

[0032] 12:55 Drying is complete.

[0033] The d...

Embodiment 2

[0035] The preparation technology of ceftriaxone sodium of the present invention is as follows:

[0036] Add 50ml of dichloromethane, 50ml of ethanol, 18ml of triethylamine, and 5ml of water into a three-necked flask, stir and cool down under nitrogen protection until the temperature is 5°C, add 20g of 7-ACT, 20g of AE-active ester, and 0.5g of hydrogen sulfite Sodium antioxidant; stir until the reaction is clear, add 30ml of ethanol to dilute, filter; then add dropwise sodium acetate aqueous solution, the solution is slightly cloudy, add ftriaxone sodium powder seed crystals to grow crystals, then add dropwise acetone to crystallize, and suction filter to obtain crystals The filter cake was washed with acetone and dried to obtain the finished product.

Embodiment 3

[0038] The preparation technology of ceftriaxone sodium of the present invention is as follows:

[0039] Add 50ml of dichloromethane, 40ml of ethanol, 18ml of triethylamine, and 8ml of water into a three-neck flask, stir and cool down under nitrogen protection until the temperature is 8°C, add 20g of 7-ACT, 20g of AE-active ester, and 0.45g of bisulfite Sodium antioxidant; stir until the reaction is clear, add 35ml of ethanol to dilute, filter; then add dropwise sodium acetate aqueous solution, the solution is slightly cloudy, add ftriaxone sodium powder seed crystals to grow crystals, then add dropwise acetone to crystallize, and suction filter to obtain crystals The filter cake was washed with acetone and dried to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com