New use of gene reconstituted urokin as origin

A technology of pro-urokinase and gene recombination, which can be applied to medical preparations containing active ingredients, drug combinations, blood diseases, etc., and can solve the problems that there is no Pro-uk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

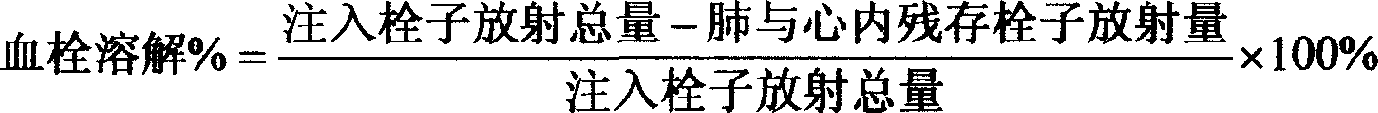

Method used

Image

Examples

Embodiment

[0082] Cloning of Prourokinase Gene and Construction of Expression Vector

[0083] (1) Construction and cloning of the full-length cDNA gene of human prourokinase: Detroit 562 cells were induced with myristyl ester (PMA), and the total RNA of the cells was extracted by the acid thiocyanate-phenol-chloroform method, and Oligo(dT)-fiber Separation of poly(A) by plain column chromatography + ) RNA, the cDNA library of Detroit 562 cells was constructed by reverse transcription and dG·dC tailing recombination technology, and the positive clones containing the gene fragment encoding urokinase were obtained by screening. Using artificially synthesized oligonucleotide fragments and DNA recombination technology, the full-length cDNA gene of human prourokinase was constructed and cloned into the pUC19 plasmid, and the PMM-UK recombinant plasmid was obtained, which was confirmed by sequencing. The 5' end of the gene contains Hind III and EcoR1 single restriction sites, and the 3' end co...

Embodiment 2

[0088] Transfection and screening of highly expressed CHO engineered cells

[0089] Transfect 20-40 μg of pMTSV-du plasmid DNA into CHO-dhfr- cells by calcium phosphate co-precipitation method, first screen with HAT selection medium, and then replace with 1-3×10 -8 The selection medium of M MTX is double-selected by dhfr and MTX, and the positively transformed cells expressing pro-urokinase activity are subjected to multiple subcloning and MTX pressurized amplification of the gene, induced by zinc ions, and finally screened to highly express urokinase original cell line.

Embodiment 3

[0091] Cultivation and scale-up of CHO engineered cells

[0092] CHO engineered cells consist of square flask (monolayer adherent culture)-spinner bottle (monolayer adherent culture)-stirred flask (porous microcarrier culture)-5L Celligen reactor (porous microcarrier culture)-30L Biostat UC reactor ( Porous microcarrier culture) step by step scale-up culture. Since the cells can be automatically transferred between the carrier full of cells and the empty carrier, when each stage of scale-up culture is carried out, an appropriate amount of medium and treated porous microcarriers are pre-added in a larger-scale reactor, and the porous microcarriers full of cells The microcarriers are directly approached to the next-stage reactor through the pipeline. The control pH is 7.0±0.5, DO is 7%-40%, temperature is 37.0±0.1°C, stirring speed is 70r / min-90r / min. The concentration of porous microcarrier is 2g / L-g / L culture medium. The continuous culture method of batch type medium exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com