Method for preparing crystal of lycopene and concentrate

A technology of lycopene and concentrate is applied in the field of food processing, which can solve the problems of low product purity, long process flow, increased loss, etc., and achieve the effects of high crystal purity, simple and easy process flow and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

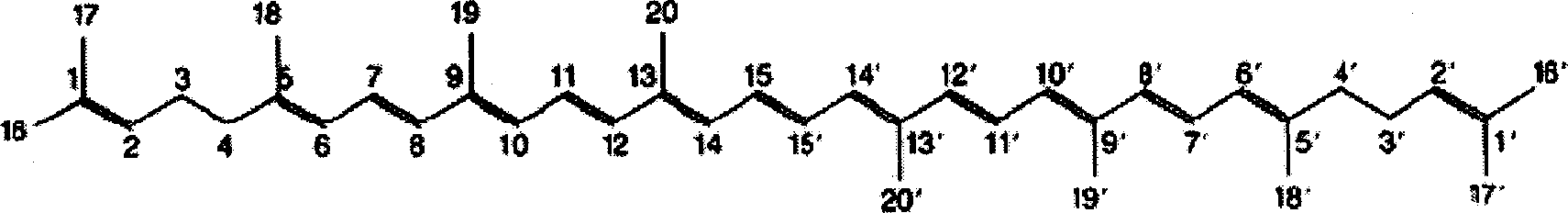

Image

Examples

Embodiment 1

[0030] Mix 100g of tomato paste with 200ml of sodium carbonate solution with a concentration of 0.5mol / L, and keep the temperature at 35°C for 40 minutes while stirring;

[0031] Then slowly add dilute sulfuric acid solution to neutralize and foam until the pH value of the solution is 4.0, and the mixed solution is centrifuged, and the rotating speed of the centrifuge is 5500 rpm;

[0032] Add 100ml of 95% ethanol to the centrifuged solid part, stir at 40°C for 10 minutes, centrifuge, the speed of the centrifuge is 6000 rpm, and the centrifuged ethanol solution recovers ethanol through vacuum distillation;

[0033] Add 200ml of acetone to the tomato paste residue obtained after alcohol treatment and centrifugal separation, extract at 50°C for 1 hour, and the stirring speed is 120 rpm, then suction filter the resulting mixed solution, and rinse the tomato paste residue with 30ml of acetone to obtain 210ml of extract, and the remaining tomato paste residue was extracted for the ...

Embodiment 2

[0037] Mix 100g of tomato paste and 200ml of sodium carbonate solution with a concentration of 0.1mol / L, and keep the temperature at 30°C for 30 minutes while stirring;

[0038] Then slowly add dilute sulfuric acid solution to neutralize and foam until the pH value of the solution is about 4.5, and the mixed solution is centrifuged, and the rotating speed of the centrifuge is 5500 rpm;

[0039] Add 300ml of methanol to the centrifuged tomato paste residue, stir at 25°C for 30 minutes, then filter the mixture with suction, and recover the methanol from the separated methanol solution through vacuum distillation;

[0040] Put the tomato paste residue separated by alcohol treatment into 200ml of methyl acetate for extraction, extract at 55°C for 60 minutes, the stirring speed is 200 rpm during the extraction process, and obtain 185ml of extract by suction filtration, and continue to add the extracted filter residue 100ml of methyl acetate was extracted for the second time, and th...

Embodiment 3

[0044] Mix 100g of tomato peels separated from the seeds by skin and 100ml of saturated potassium carbonate solution, and keep the temperature at 20°C for 60 minutes under stirring;

[0045] Then slowly add 200ml of sulfuric acid solution for neutralization and foaming until the pH of the solution is 5.0, then filter with suction;

[0046] Add 200ml of isopropanol to the obtained tomato skin residue, stir at a constant temperature of 40°C for 15 minutes, filter with suction, and recover isopropanol from the separated isopropanol solution by vacuum distillation;

[0047] The alcohol-treated tomato pomace was extracted with 700ml of n-hexane, extracted at 55°C for 60 minutes, and then suction filtered to obtain a lycopene extract;

[0048] Evaporate the lycopene extract to 10ml on a rotary evaporator, add 5ml of absolute ethanol and crystallize at 0°C for 3 hours, filter, and dry at 15°C to obtain 26.9mg of lycopene crystal product, lycopene The content is 74.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com