Thermosetting resin composition, multilayer body using same, and circuit board

A resin composition, thermosetting technology, applied in the direction of circuit substrate materials, multilayer circuit manufacturing, synthetic resin layered products, etc., can solve the problem of not being obtained, and achieve excellent dielectric properties, high thermal decomposition temperature, and small thermal expansion coefficient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0329] Hereinafter, the present invention will be explained more specifically based on examples and comparative examples, but the present invention is not limited to these. A person skilled in the art can make various changes, corrections and changes to the present invention without departing from the scope of the present invention.

[0330] In addition, the fluidity, layerability, and volatile content of the resin sheet containing the thermosetting resin composition of the present invention are calculated, and the dielectric properties, glass transition temperature, and soldering properties of the cured resin sheet obtained by heating and curing the resin sheet The heat resistance and flame retardancy were measured and evaluated according to the following methods.

[0331] [fluidity]

[0332] Using a shear system dynamic viscoelasticity measuring device (CVO, manufactured by Bohling), the complex viscosity (Pa·s) of the resin sheet before heat curing was measured under the follow...

Synthetic example 1

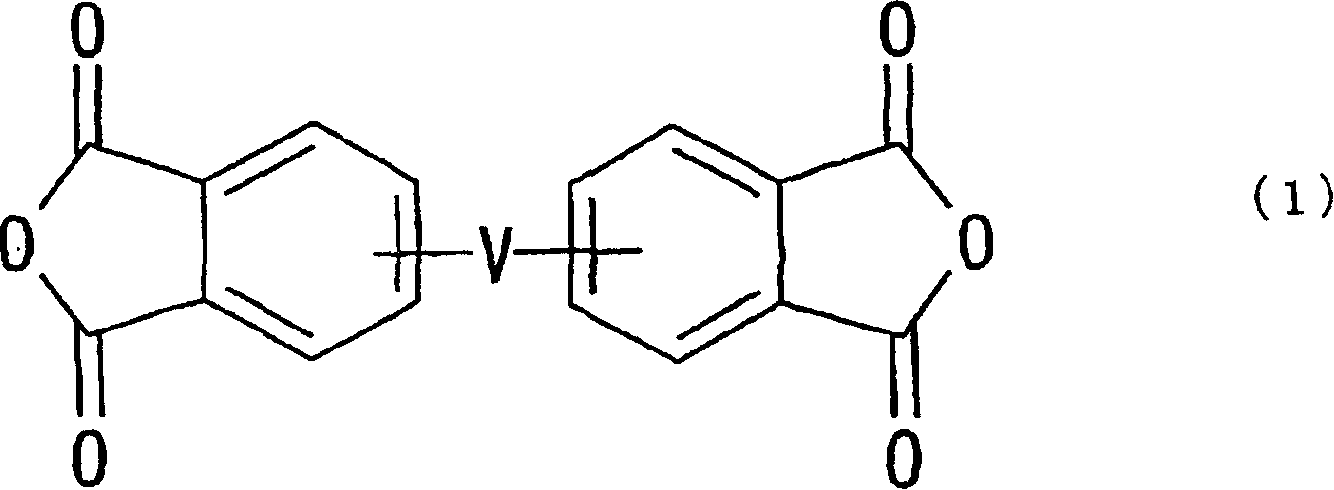

[0362] [Synthesis Example 1; Polyimide resin]

[0363] In a 2000ml glass flask, add 0.95 equivalents of 1,3-bis(3-aminophenoxy)benzene (hereinafter called APB) and 0.05 equivalents to dimethylformamide (hereinafter referred to as DMF) 3,3'-dihydroxy-4,4'-diaminobiphenyl (manufactured by Wakayama Seiki Co., Ltd.), stirred and dissolved in a nitrogen atmosphere to make a DMF solution. Next, make the inside of the flask into a nitrogen atmosphere, while stirring the DMF solution with ice water, add 1 equivalent of 4,4'-(4,4'-isopropylidene diphenoxy) diphthalic anhydride (Hereinafter referred to as IPBP), and further stirred for 3 hours to obtain a polyamic acid solution. In addition, the amount of DMF used is determined so that the monomer concentration of APB, 3,3'-dihydroxy-4,4'-diaminobiphenyl and IPBP is 30% by weight.

[0364] Transfer 300 g of the above polyamic acid solution to a container coated with fluororesin, and heat it under reduced pressure for 3 hours in a vacuum ove...

Synthetic example 2

[0365] [Synthesis Example 2; Synthesis of phosphazene compound as raw material]

[0366] In a 5L flask equipped with a reflux cooler, a thermometer, a stirrer, a phosphorus trichloride dropper, and a chlorine gas blowing pipe, 2.5L of chlorobenzene, 182.5g (3.4 mol) of ammonium chloride and 2.5g of zinc chloride are charged to obtain a mixture Dispersions. The dispersion was heated to a temperature of 130°C, and 425.5 g of phosphorus trichloride was dropped at a rate of 9 g / min over 48 minutes under reflux, and 227 g of chlorine gas was supplied at a rate of 5 g / min over 46 minutes. After supplying phosphorus trichloride and chlorine gas, reflux (131°C) was performed for another 150 minutes to complete the reaction. Next, unreacted ammonium chloride was removed by suction filtration, and the filtrate was distilled off chlorobenzene at 30 to 50°C under a reduced pressure of 1.0 to 3.0 hPa to obtain 352 g of a reaction product. Based on phosphorus trichloride, the yield of the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com