Apparatus for controlling thickness of digital optical film

An optical film thickness and controller technology, applied in optics, optical components, program control, etc., can solve problems such as affecting signal processing, inability to achieve, changing filtering parameters, etc., to improve detection sensitivity and signal-to-noise ratio, and improve yield. and repetitive, simple hardware design effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

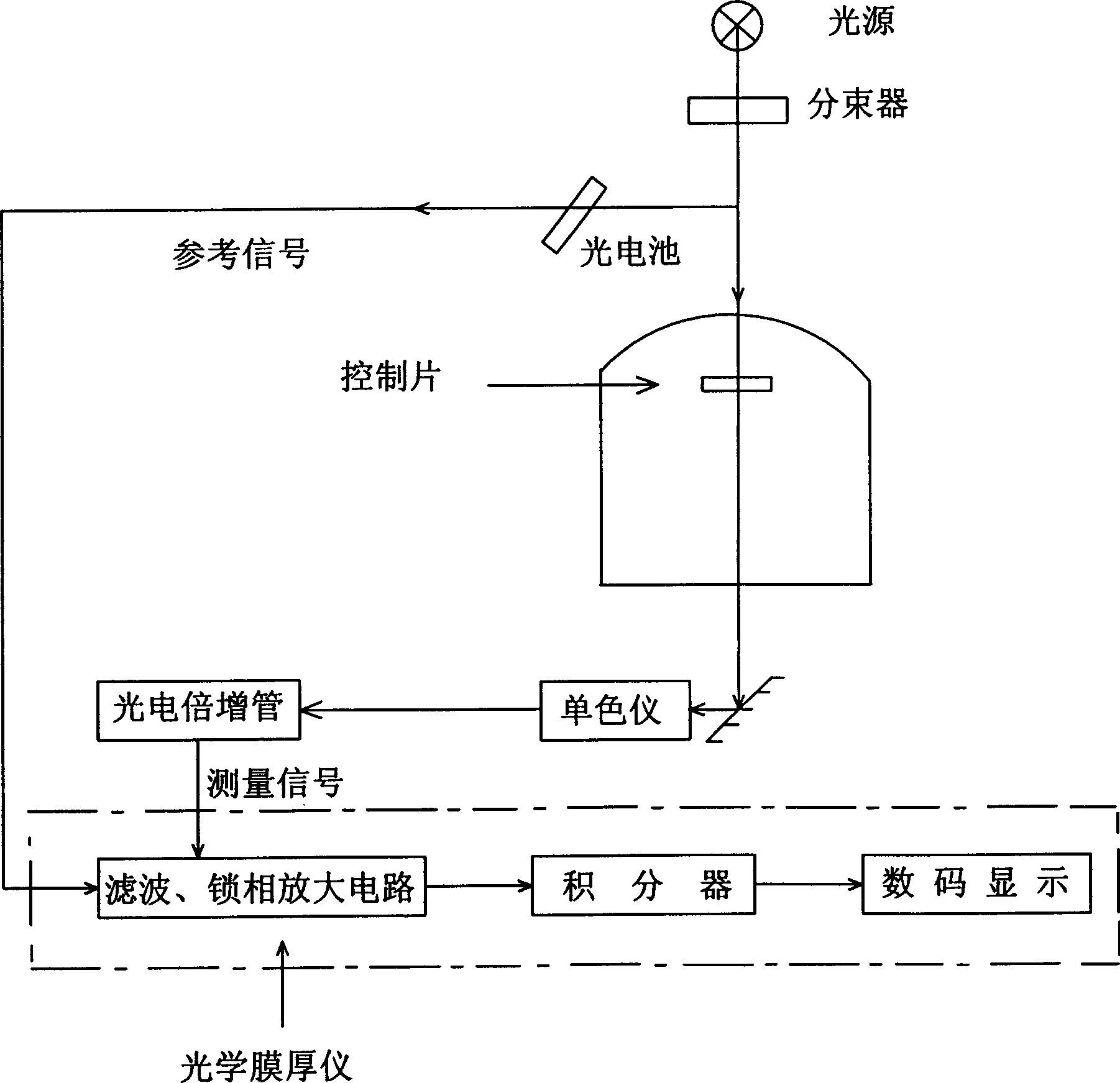

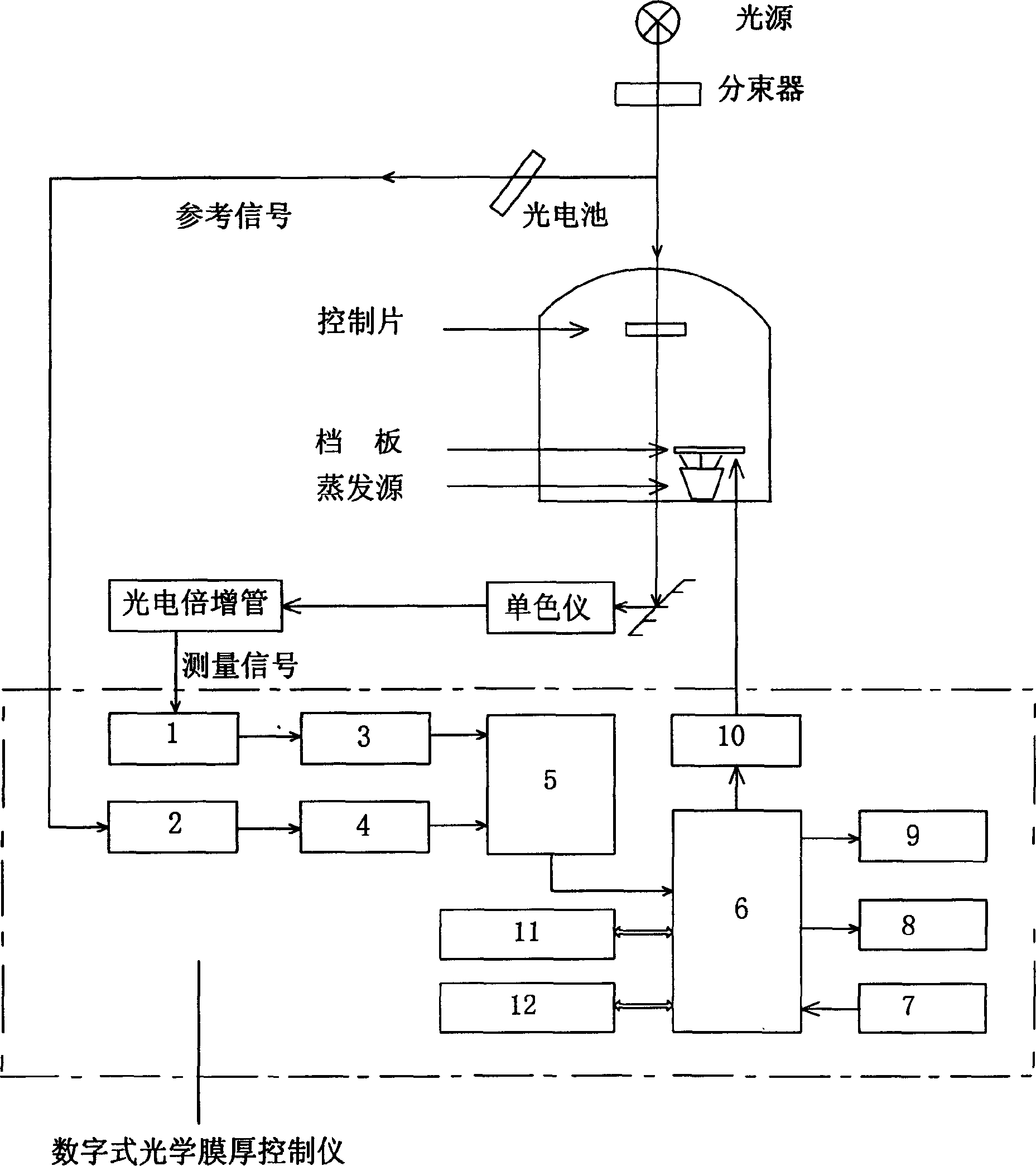

[0033] see figure 2 , image 3 , the digital optical film thickness controller of the embodiment of the present invention is provided with measuring amplifier 1, reference amplifier 2, measuring filter 3, reference filter 4, A / D module 5, embedded computer system 6, touch keyboard 7, LCD liquid crystal Display 8, LED digital tube display 9, switch 10, memory 11 and communication interface 12, measurement amplifier 1 is connected with measurement signal and measurement filter 3, reference amplifier 2 is connected with reference signal and reference filter 4, measurement filter 3, The reference filter 4 is connected with the A / D module 5, and the embedded computer system 6 is connected with the A / D module 5, the touch keyboard 7, the LCD liquid crystal display 8, the LED digital tube display 9, the switch 10, the memory 11 and the communication interface 12 , the LED digital tube display 9 is used to display the light value, and the LCD liquid crystal display 8 is used to disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com