Method for preparing Nano platinum carried catalysis electrode in Nano crystal sensitized solar battery

A technology of solar cells and nano-platinum, applied in battery electrodes, capacitor electrodes, photosensitive equipment, etc., can solve the problems of high platinum loading, limit the amplification and preparation of platinum loading electrodes, and unfavorable battery practicality, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Add 4ml of sodium acrylate aqueous solution with a concentration of 1.0mol / L to 250ml with a concentration of 8.23×10 -4 K in mol / L 2 PtCl 6 50ml of ethanol was added to 40ml of the above solution. After bubbling nitrogen for 15 min, heat in an autoclave at 100 °C for 12 h to make PtCl 6 2- Reduction, to obtain dark brown acrylate-protected nano-platinum colloid solution.

[0027] Preparation is the dodecylmercaptan of solvent with toluene: stearic acid=5: 1 blend solution, wherein the concentration of stearic acid is 5.0 * 10 -3 mol / L. On the L-B film instrument (JC-1 type), the monomolecular film of the blend solution is transferred to the FTO conductive glass (SnO doped with F) with a surface pressure of 30mN / m and a lifting speed of 6mm / min. 2 , Sheet resistance is 20 ~ 30Ω / □) on the surface. The conductive substrate after hanging the film was immersed in the nano-platinum hydrosol for self-assembly, and the self-assembly time was 4 days. After the electrode...

Embodiment 2

[0035] By replacing the alkyl mercaptan in Example 1 with hexadecyl mercaptan and the ratio of stearic acid to 7:1, a nanometer-loaded platinum catalytic electrode with similar performance can be prepared.

Embodiment 3

[0037] The preparation of nano-platinum colloid is the same as in Example 1.

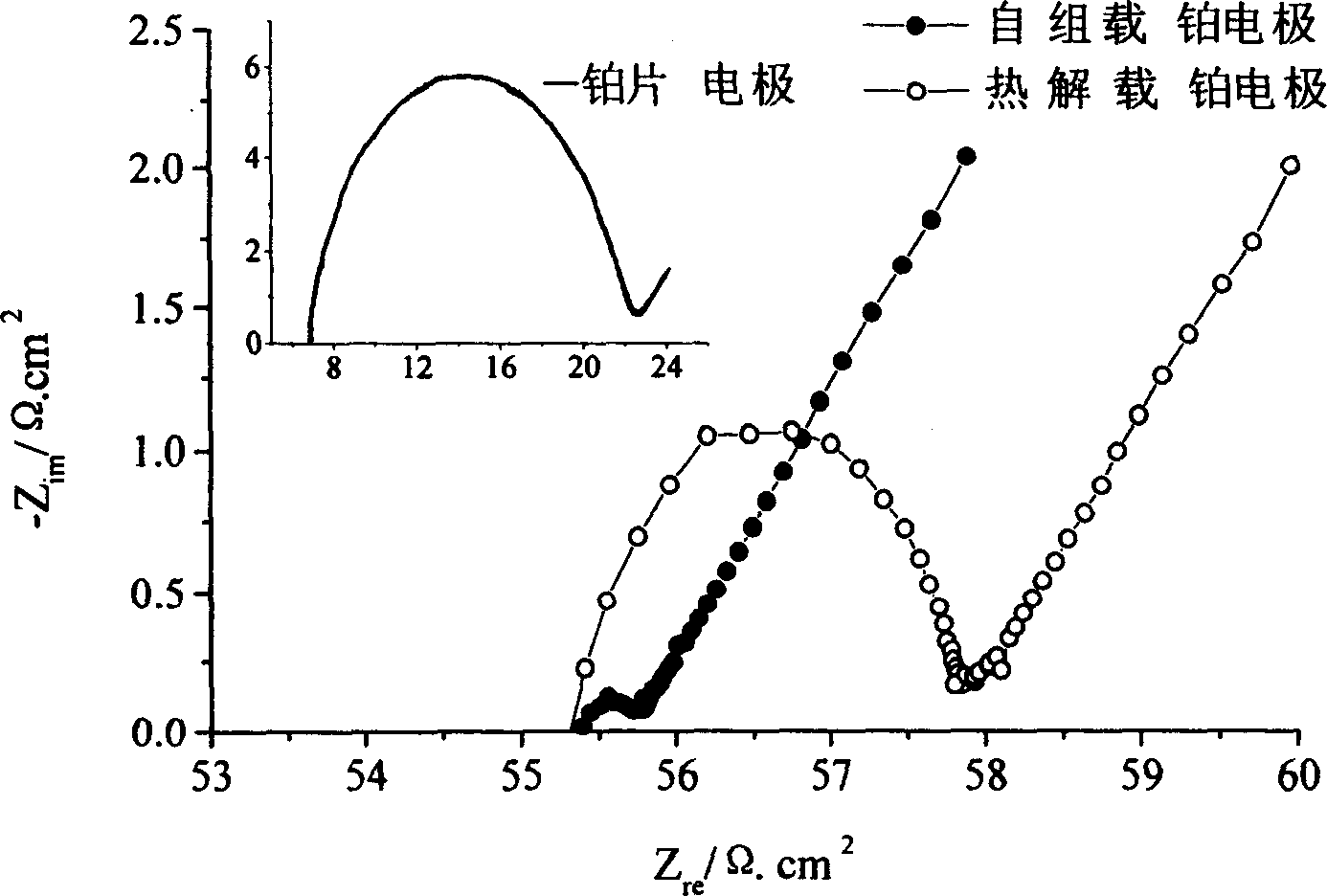

[0038] Prepare 50ml, the xylene solution of 10% (volume ratio) silane coupling agent, conduction glass is immersed in the above-mentioned solution, under N 2 Under the protection of , reflux at 100-150□ for 12 hours. The electrodes after silanization modification were in N 2 Washed with xylene and methanol in turn under the protection of the protection, and then immersed in the prepared nano-platinum colloid solution for self-assembly, the self-assembly time is 1 to 4 days. After the electrode was taken out, it was rinsed with twice distilled water to remove the physically adsorbed nano-platinum particles on the surface of the electrode, dried in air at room temperature, and then placed in a muffle furnace for sintering at 380°C for 15 minutes. The charge transfer resistance R of the prepared platinum-loaded catalytic electrode ct 0.6Ω.cm 2 (using the same test conditions as in Example 1), the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com