Method for preparing highly active Fe/Sn ion co-doped nano phtocatalyst of titanium dioxide

A co-doping, photocatalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of large loss of active components, difficult recovery, and low photogenerated current-carrying interface transfer rate, etc. Achieve the effect of improving photocatalytic activity and photocatalytic degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

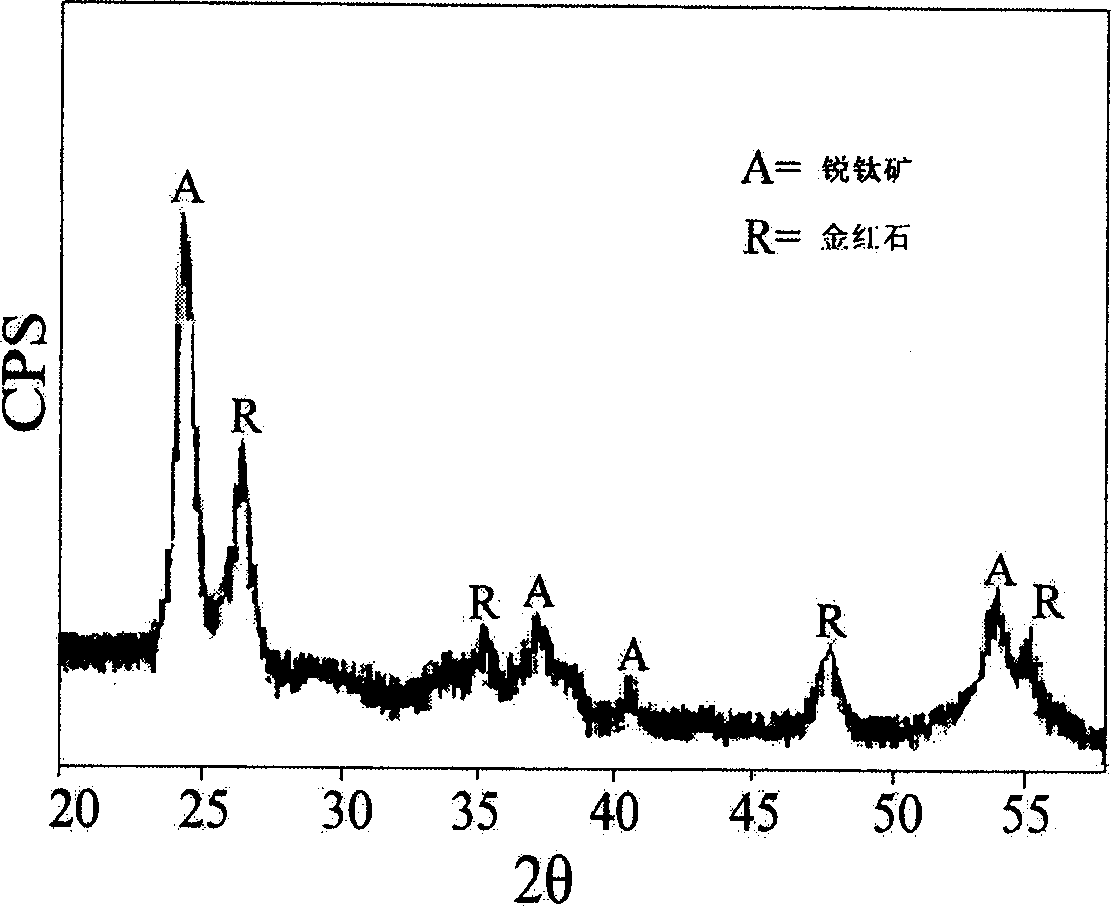

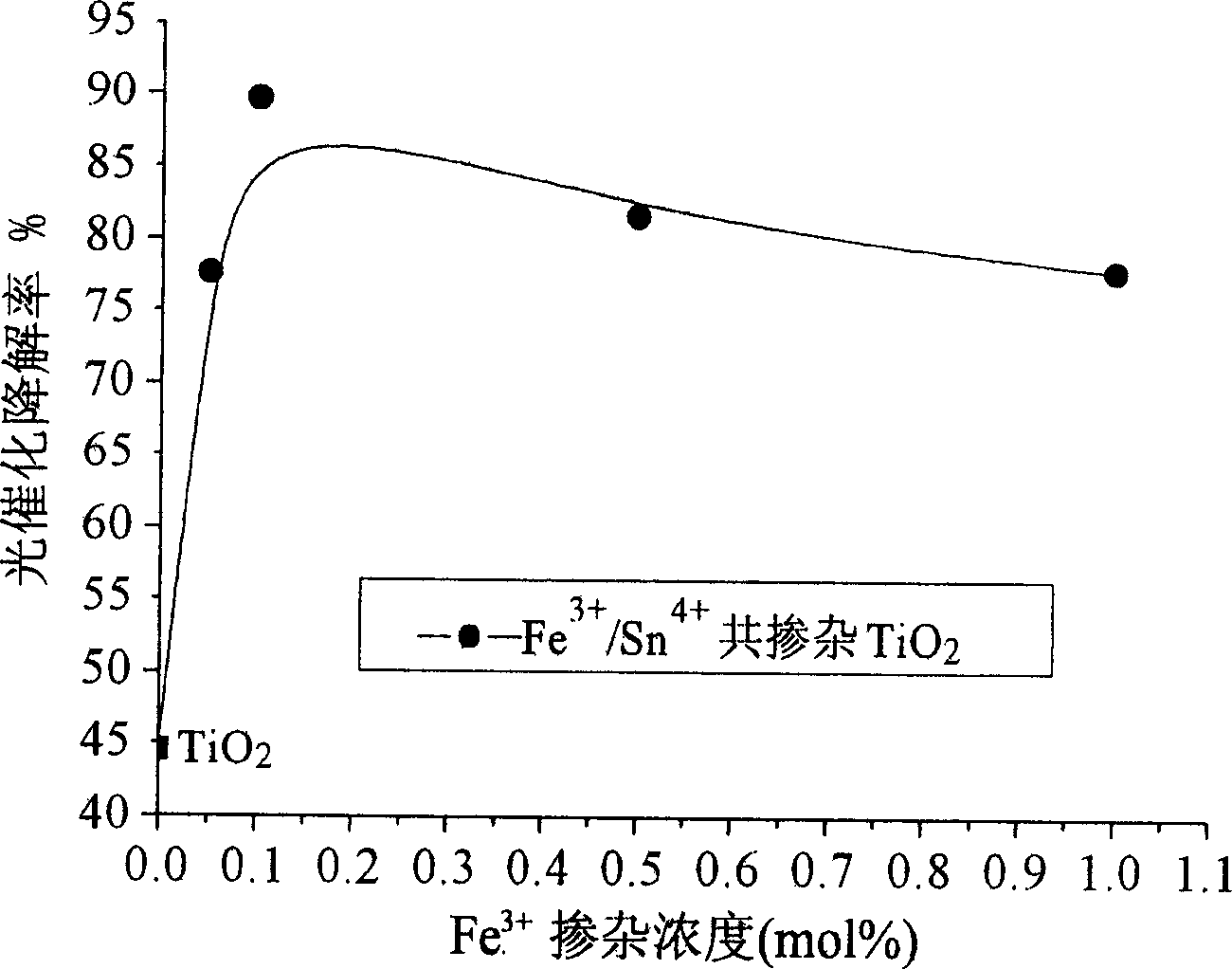

[0018] First drop 17ml of tetrabutyl titanate into 23ml of absolute ethanol, continue magnetic stirring, then slowly add 11ml of acetylacetone as a complexing agent, and obtain a uniform solution a after full reaction; add 2.00g of SnCl 4 ·5H 2 O and 0.02g Fe(NO 3 ) 3 9H 2 O was dissolved in 47ml of absolute ethanol, then 2ml of distilled water and 0.2ml of nitric acid were added dropwise, and magnetically stirred to obtain a uniform solution b. The reaction temperature is controlled at 30°C, and the solution b is slowly added dropwise to the solution a to carry out the hydrolysis reaction. Fe will eventually form 3+ / Sn 4+ ion doped TiO 2 The sol was sealed and aged at room temperature.

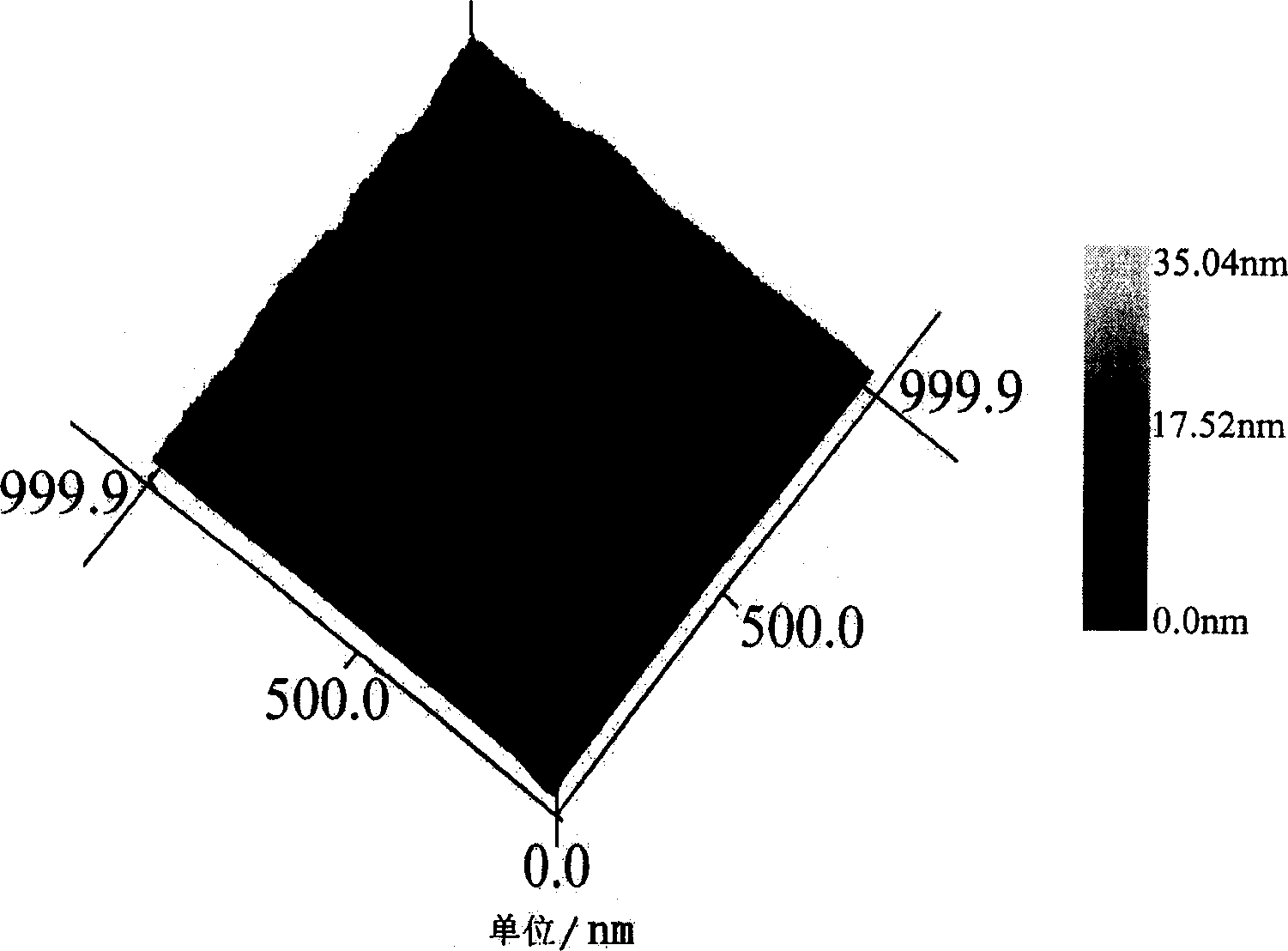

[0019] Immerse the pretreated clean glass tube (1cm×2.5cm) into the prepared sol solution at a speed of 4cm / min and let it stand for 2min. After the liquid level is stable, pull it vertically upward at the same pulling speed, and the wet film Place it at room temperature for 5 minute...

Embodiment 2

[0022] The processing step of the present embodiment is basically the same as that of embodiment 1, the difference is that Fe(NO 3 ) 3 9H 2 The doping amount of O was 0.10 g. The photocatalytic activity test test shows that the 0.5% Fe of the present embodiment 3+ / 11.41%Sn 4+ co-doped TiO 2 The photocatalytic degradation rate of photocatalyst film to methyl orange solution was 81.56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com