Cleaning production process of extracting L-isoleucine from fermented liquor using ion-exchange

An ion exchange method and isoleucine technology are applied in the field of zero discharge of ammonium-containing wastewater, which can solve the problems of treating symptoms but not the root cause, difficulty in offsetting project construction capital investment and operation costs, and difficulty in rooting out the problems, so as to reduce production costs and reduce environmental protection treatment. Difficulty and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

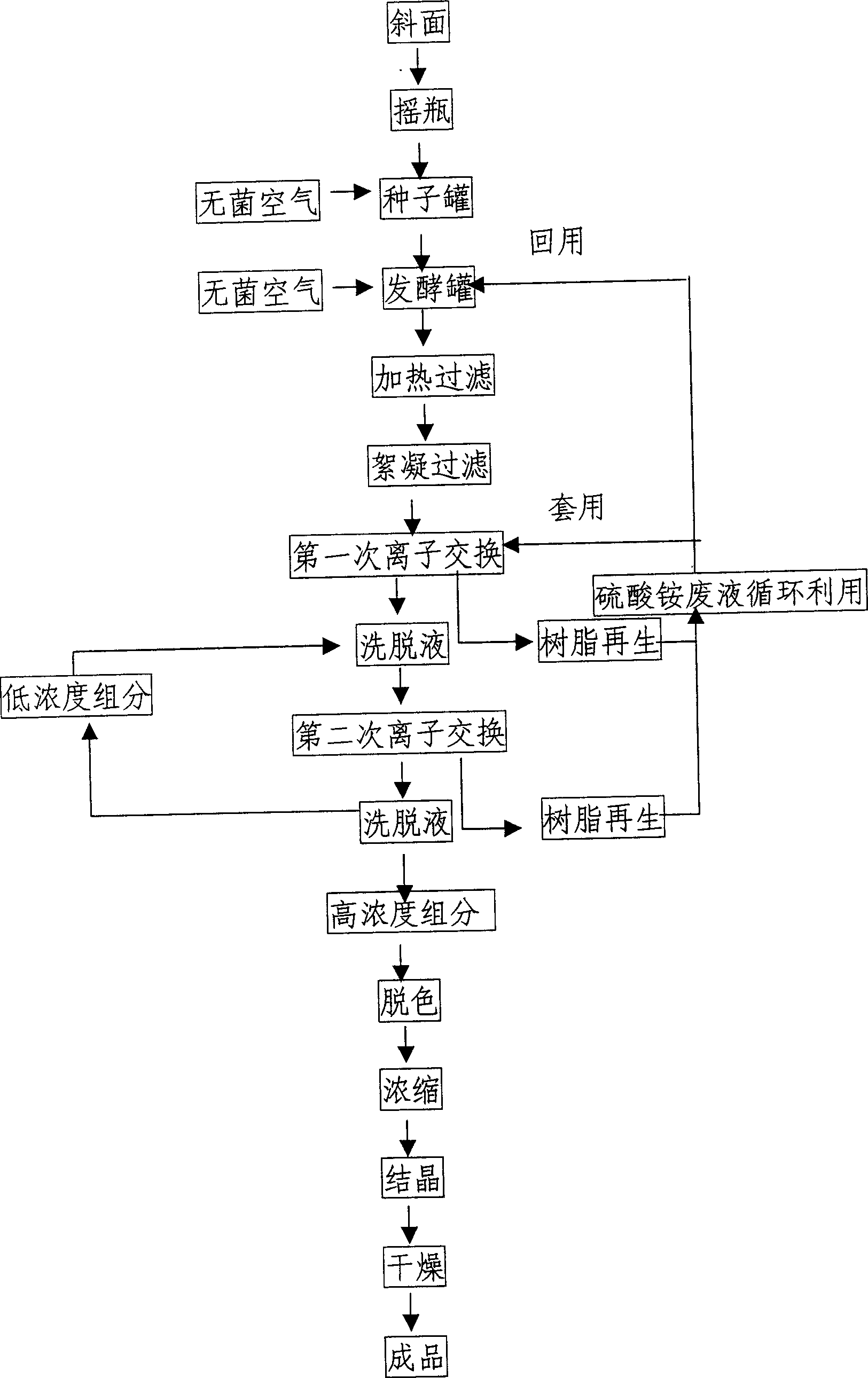

Method used

Image

Examples

Embodiment 1

[0025] The extraction of embodiment 1, L-isoleucine

[0026] 1) After the fermentation of L-isoleucine is completed, directly heat the fermenter to 80-85° C. for 15-20 minutes, then filter, remove the slag to obtain the filtrate, and store it in the flocculation tank.

[0027] 2) Adjust the pH of the filtrate to 2.0-2.5, add chitosan to a concentration of 30-100mg / L, let stand at 20-50°C for 30-60 minutes, then filter, and store the filtrate in a storage tank.

[0028] 3) Adsorption with strong acidic hydrogen ion exchange resin column, flow rate 0.5 ~ 10m 3 / m 3 resin hours.

[0029] 4) After the adsorption is saturated, rinse with hot water to remove impurities, and then use 0.2-1.0 molar concentration of ammonia water, add ammonium-containing wastewater (ammonia water: ammonium-containing wastewater volume ratio is 1:0.5-1.5) to elute, and the flow rate is 0.5-10m 3 / m 3 resin hours.

[0030] 5) Add the low-concentration eluted components in step 6 to the eluent to adj...

Embodiment 2

[0033] Embodiment 2, the shaking flask fermentation test that replaces ammonium sulfate in the culture medium with ammonium-containing waste water

[0034] Get the ammonium sulfate in the ammonium sulfate in the fermented medium that the ammonium-containing waste water that ion-exchange resin regeneration produces among the embodiment 1 replaces partly, be used for the shake flask test of fermentative production:

[0035] 1) The strain used, Brevibacterium lactofermentum (Brevibacterium lactofermentum) ATCC 13869;

[0036] 2) Fermentation medium formula, glucose 140g / L, corn steep liquor 20g / L, ammonium sulfate 10g / L, ammonium-containing wastewater 100ml / L, biotin 50μg / L, KH 2 PO 4 1g / L, MgSO 4 ·7H 2 O0.5g / L, CaCO 3 15g / L, adjust the pH to 6.8-7.0 with NaOH;

[0037] 3) Liquid volume, 25ml fermentation broth in 50ml triangular bottle;

[0038] 4) Fermentation conditions, the vibration frequency of the reciprocating shaker is 100 times / min, and the fermentation temperatur...

Embodiment 3

[0041] Embodiment 3, the fermentation test of the 5L fermenter that replaces ammonium sulfate in the culture medium with ammonium-containing waste water

[0042] 1) The strains used are the same as in Example 2;

[0043] 2) Seed medium, glucose 25g / L, corn steep liquor 40g / L, ammonium sulfate 5g / L, KH 2 PO 4 10g / L, MgSO 4 ·7H 2 O5g / L, CaCO 3 10g / L;

[0044] 3) Inoculation amount, 5%;

[0045] 4) fermentation medium, with embodiment 2;

[0046] 5) Liquid volume, 3L;

[0047] 6) Fermentation conditions, ventilation rate 180L / hour; stirring speed 500-600 rpm, fermentation temperature 32°C;

[0048] 7) Fermentation cycle, 72 hours;

[0049] 8) Acid production rate, 24.7g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com