Process for preparing bismuth silicate nano powder and use

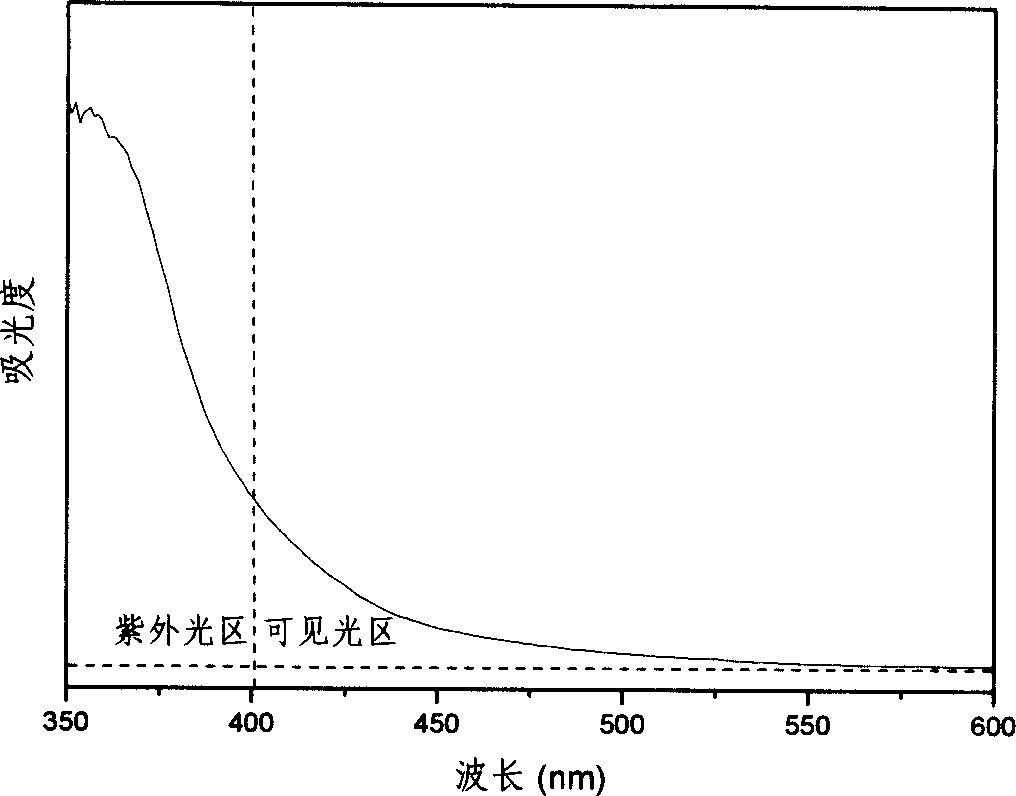

A technology of nano-powder and bismuth silicate, which is applied in the direction of chemical instruments and methods, silicon compounds, bismuth compounds, etc., can solve the problems that there are no relevant literature reports on nano-powder, achieve good application prospects, simple process flow, excellent The effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

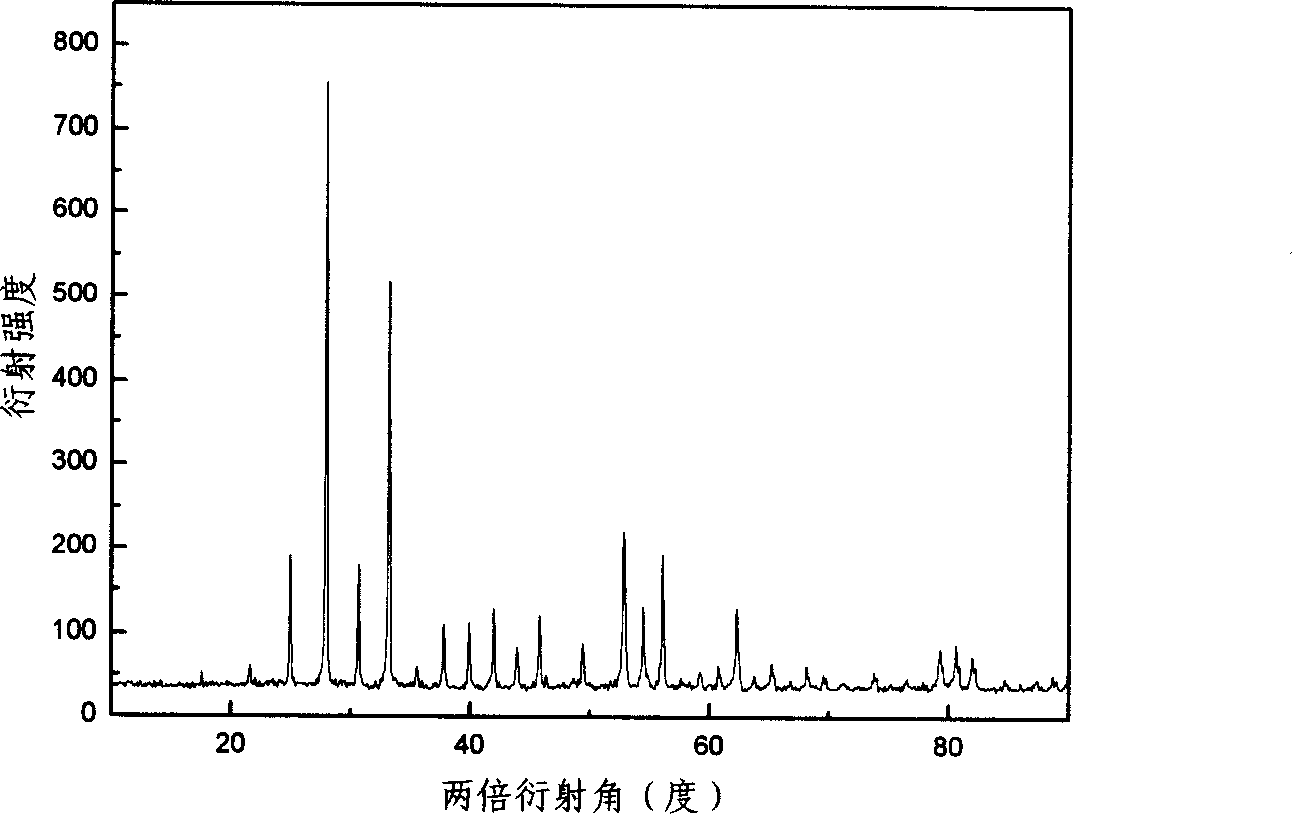

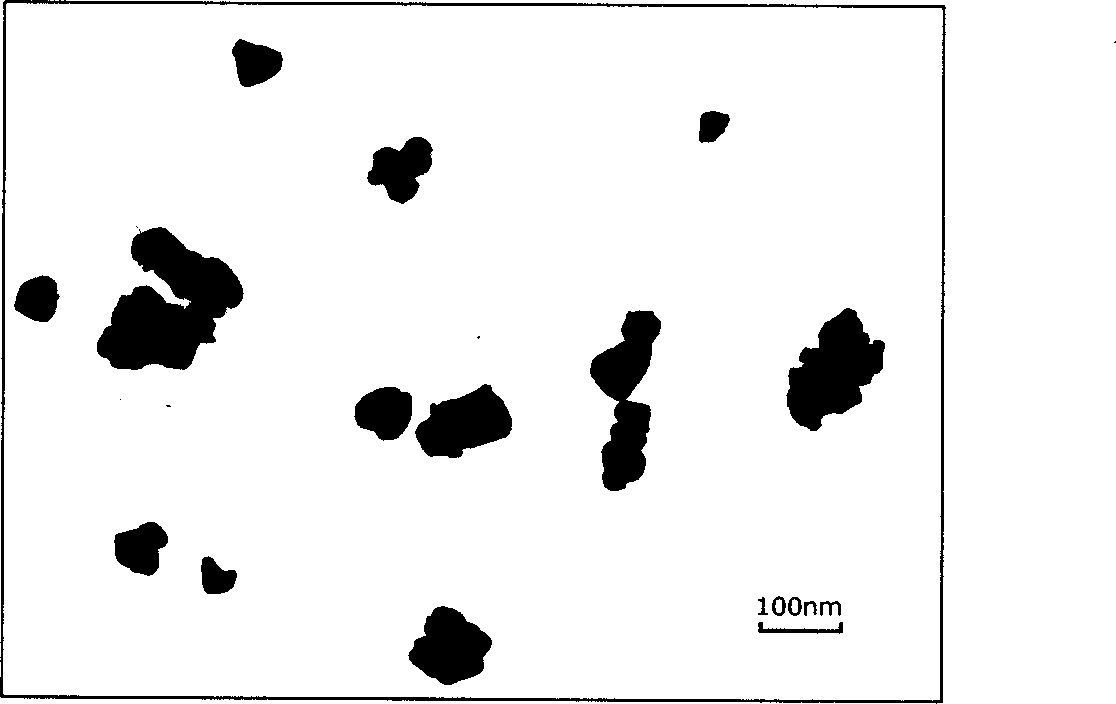

Embodiment 1

[0032] 0.12mol bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) dissolved in 180ml glacial acetic acid (CH 3 COOH), and then dropwise added 0.01mol tetraethoxysilane ((C 2 h 5 O) 4 Si), while adding 60ml ethylene glycol dimethyl ether (CH 3 OCH 2 CH 2 OH) as a co-solvent to adjust the viscosity of the solution, fully stirred to form a uniform sol. The aforementioned sol was evaporated and dried at 150° C. to obtain a precursor powder. The resulting precursor powder was sintered at 650 °C under normal pressure for 0.75 hours to obtain Bi 12 SiO 20 Nano powder.

Embodiment 2

[0034] 0.12mol bismuth acetate (Bi(CH 3 COO) 3 ) was dissolved in 60ml absolute ethanol (CH 3 CH 2 OH), then add 0.01mol tetrapropoxysilane ((C 3 h 7 O) 4 Si), fully stirred to form a uniform sol. The aforementioned sol was evaporated and dried at 250° C. to obtain a precursor powder. The resulting precursor powder was sintered at 550 °C under normal pressure for 1.5 hours to obtain Bi 12 SiO 2 0 nanometer powder.

Embodiment 3

[0036] 0.12mol bismuth carbonate (Bi(CO 3 ) 3 ) dissolved in 100ml anhydrous isopropanol ((CH 3 ) 2 CHOH), then add 0.01mol tetramethoxysilane ((CH 2 O) 4 Si), while adding 20ml ethylene glycol dimethyl ether (CH 3 OCH 2 CH 2 OH) as a co-solvent to adjust the viscosity of the solution, fully stirred to form a uniform sol. The aforementioned sol was evaporated under negative pressure at 100° C. with a vacuum degree of -0.1 MPa to obtain a precursor powder. The resulting precursor powder was sintered at 700 °C under normal pressure for 0.5 hours to obtain Bi 12 SiO 20 Nano powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com