Method for producing biological diesel oil from leftover of edible oil process

A biodiesel and scrap technology, applied in the field of oleochemical industry, can solve the problems of harsh acid catalytic reaction conditions, and achieve the effects of controlling urban air pollution, ensuring oil safety, and reducing the amount of methanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

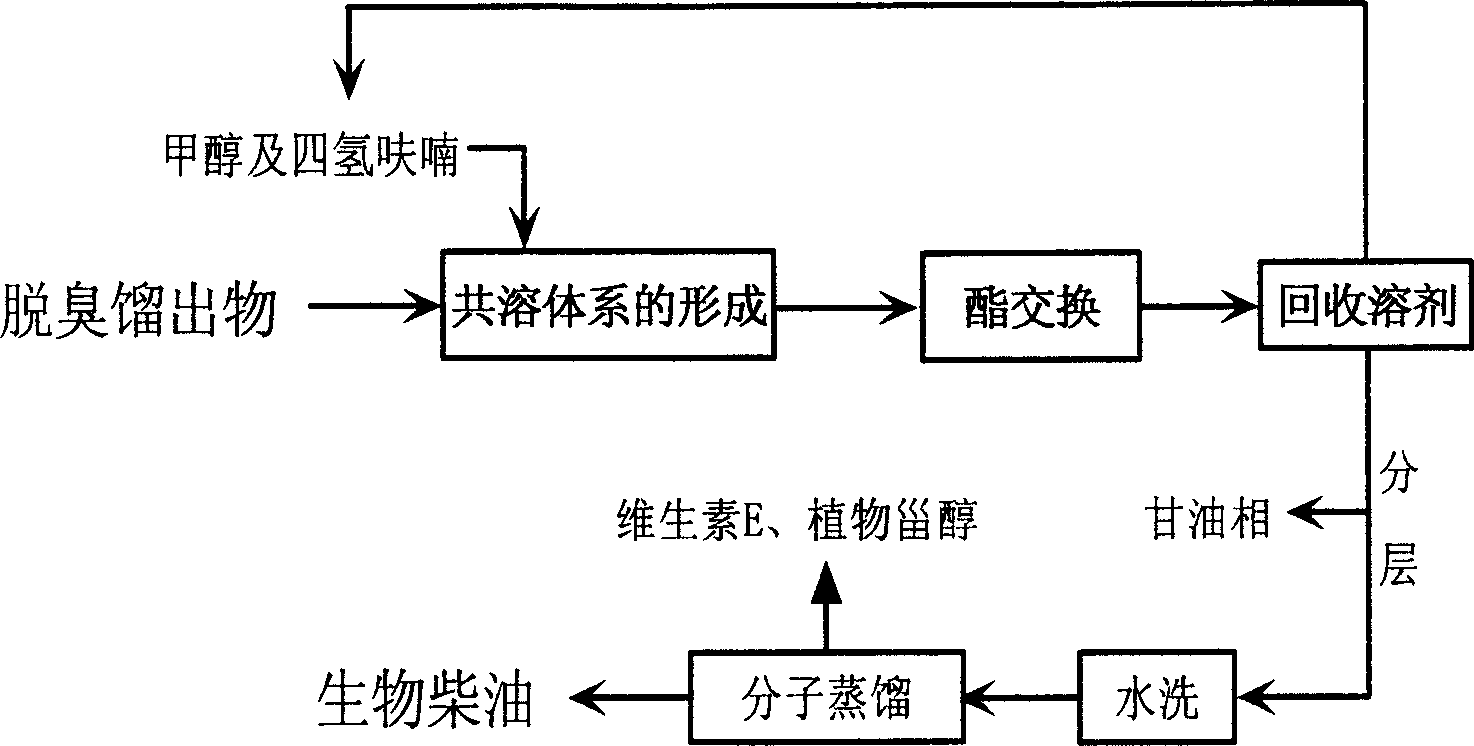

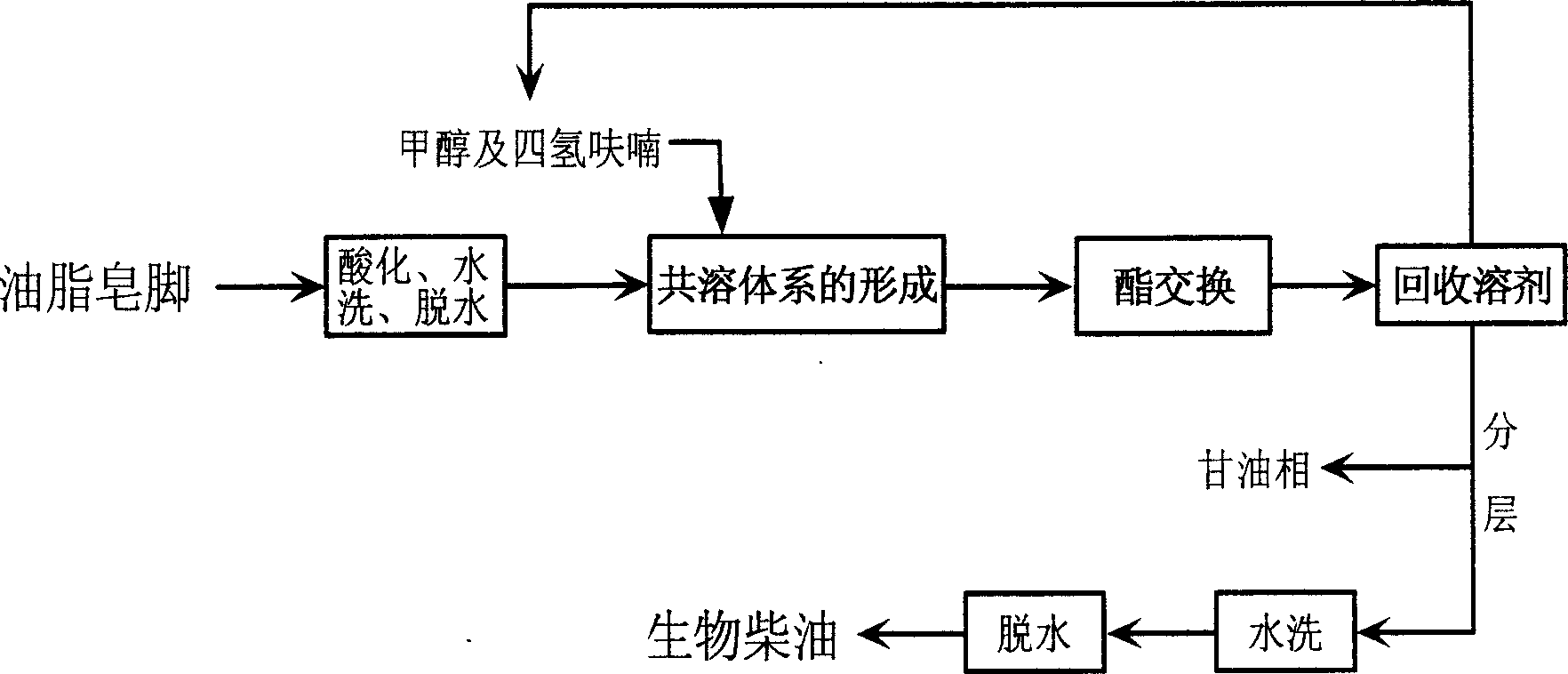

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the optimization of transesterification reaction condition

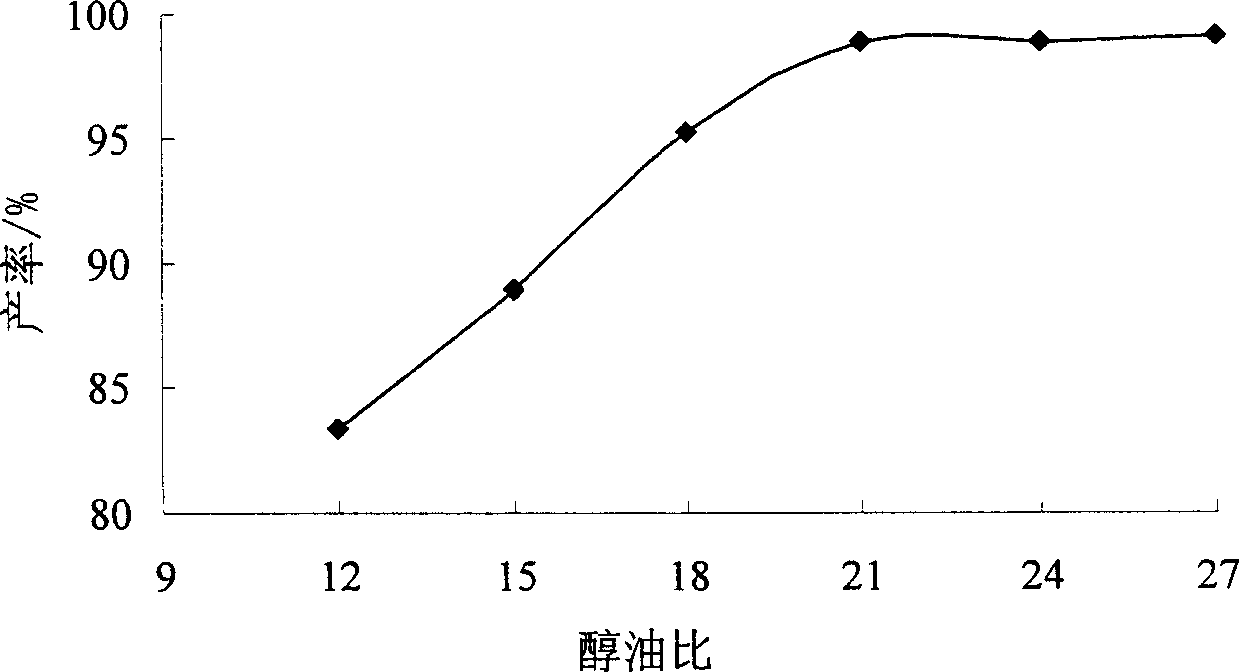

[0030] Investigate respectively the influence of alcohol-oil ratio, catalyst consumption, reaction temperature and reaction time on reaction yield by single factor optimization, see respectively Figure 3-6 .

[0031] Effect of alcohol-oil ratio on reaction yield: by image 3 It can be seen that the reaction yield reaches the optimum value when the alcohol-oil ratio reaches 21:1, and further increasing the alcohol-oil ratio has little effect on the reaction yield. According to the regression curve y=-0.021X 2 +1.3885X+11.401 (y is the amount of tetrahydrofuran (THF) added, X is the ratio of alcohol to oil), it can be seen that the amount of THF added is about 31% when the ratio of alcohol to oil reaches 21:1, and the amount of methanol added in the co-solvent system is about 31%. The volume ratio of the volume of solvent added to the system to the volume of edible oil offal is about 1.8:1. In...

Embodiment 2

[0050] Embodiment 2: Analysis of biodiesel physicochemical properties

[0051] Because the produced biodiesel will be used as an alternative fuel for diesel engine combustion, so in order to ensure that the biodiesel has good combustion performance, the physical properties of the product were analyzed according to the E DIN 51606 quality standard formulated by Germany.

[0052] main indicators

Standard Test Method

scope

detection value

iodine value

Acid value (mgKOH / g)

Monoglyceride (W%)

Diglycerides (W%)

Triglycerides (W%)

Moisture content (mg / kg)

DIN53241-1

DIN 51558-1

E DIN 51609

E DIN 51609

E DIN 51609

DIN 51773

DIN 51777-1

<115

<0.5

<0.8

<0.4

<0.4

>49

<300

105.7

0.087

0.39

0

0

53.4

132

[0053] The cetane number in the product can reflect the combustion performance of biodiesel. The cetane number of b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com