Short peptide protein powder preparation method using livestock blood as material

A protein powder and short peptide technology, which is applied in animal protein processing and other fields, can solve the problems of low amino nitrogen content, difficult digestion and absorption, and low dissolution rate of nutrients, so as to increase amino acid content, ensure biological safety, and shorten production. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

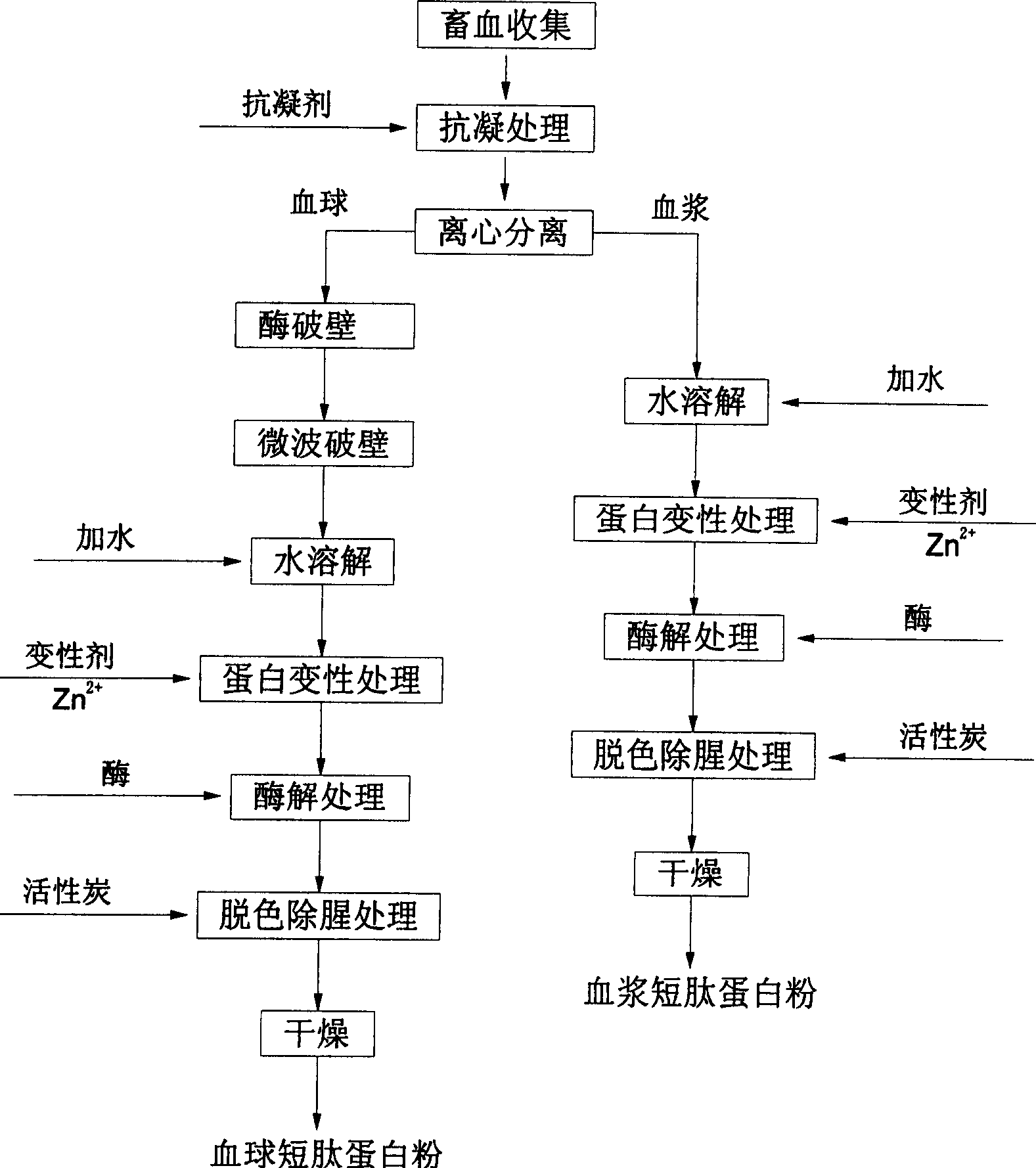

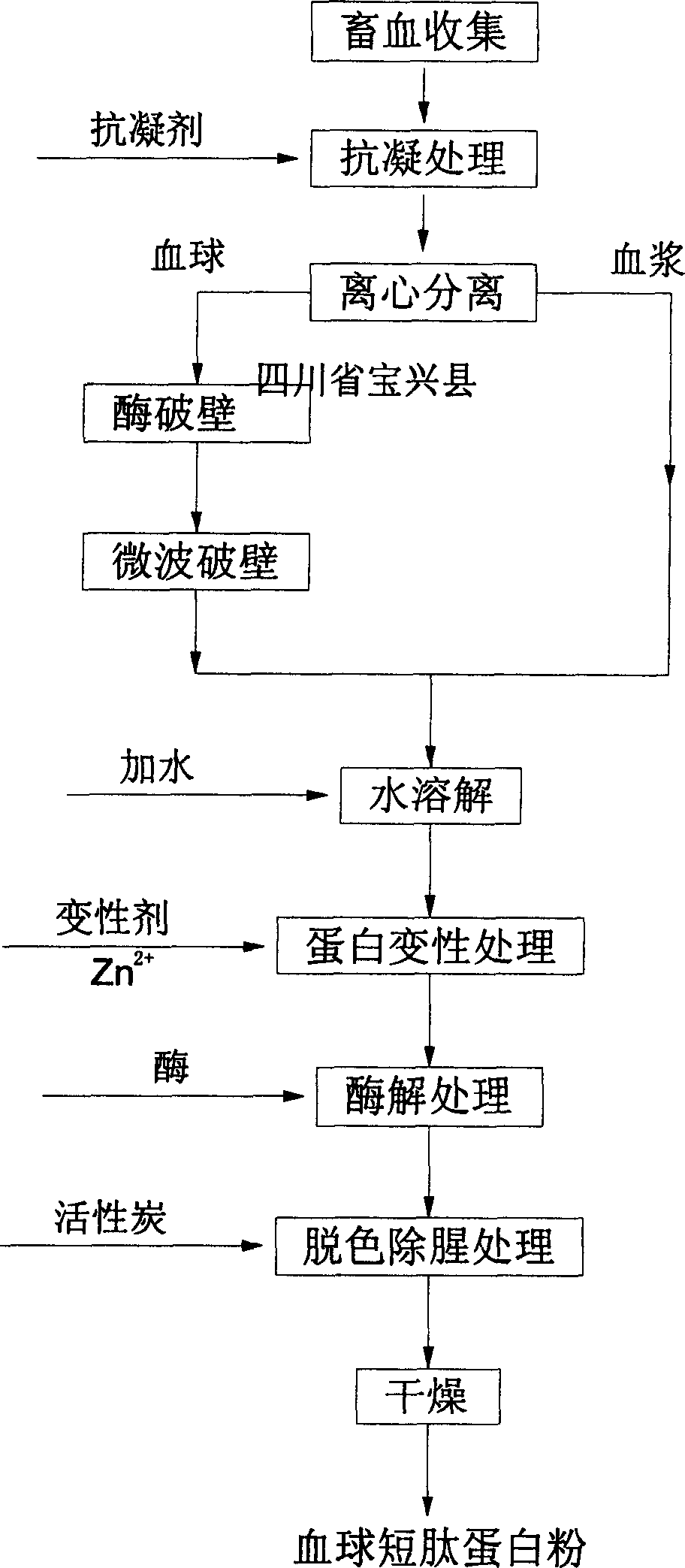

Method used

Image

Examples

Embodiment 1

[0039] A production method for preparing plasma short peptide protein powder and blood cell short peptide protein powder from livestock blood, comprising the following process steps:

[0040] 1. Use aseptic method to collect fresh livestock blood from slaughterhouses qualified for health and quarantine, and then quickly add sodium citrate for anticoagulation, and the amount added is about 6g per liter of blood.

[0041] 2. Transport the livestock blood prepared in the previous process to the processing plant with a stainless steel car, and centrifuge it with a high-speed centrifuge at a speed of about 16,000r / min for about 8 minutes. The livestock blood is divided into two parts: plasma and blood cells, and the upper layer is light yellow. Plasma raw material solution, the lower layer is dark red blood cell raw material solution.

[0042] 3. After the separation in the previous process, the blood cells are firstly lysozyme-lysed, and then treated with microwaves. The lysozyme...

Embodiment 2

[0050] A production method for preparing plasma short peptide protein powder and blood cell short peptide protein powder from livestock blood, comprising the following process steps:

[0051] 1. Use aseptic method to collect fresh livestock blood from slaughterhouses qualified for health and quarantine, and then quickly add trisodium citrate anticoagulant, and the amount added is about 8g per liter of blood.

[0052] 2. The livestock blood prepared in the previous process is transported to the processing plant with a stainless steel car, and centrifuged in a high-speed centrifuge with a speed of about 12,000r / min for about 6 minutes. The livestock blood is divided into two parts: plasma and blood cells, and the upper layer is light yellow plasma. Raw material solution, the lower layer is dark red blood cell raw material solution.

[0053] 3. For the hemocytes separated by the previous process, microwave irradiation is used to break the wall, and then lysozyme is used to break ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com